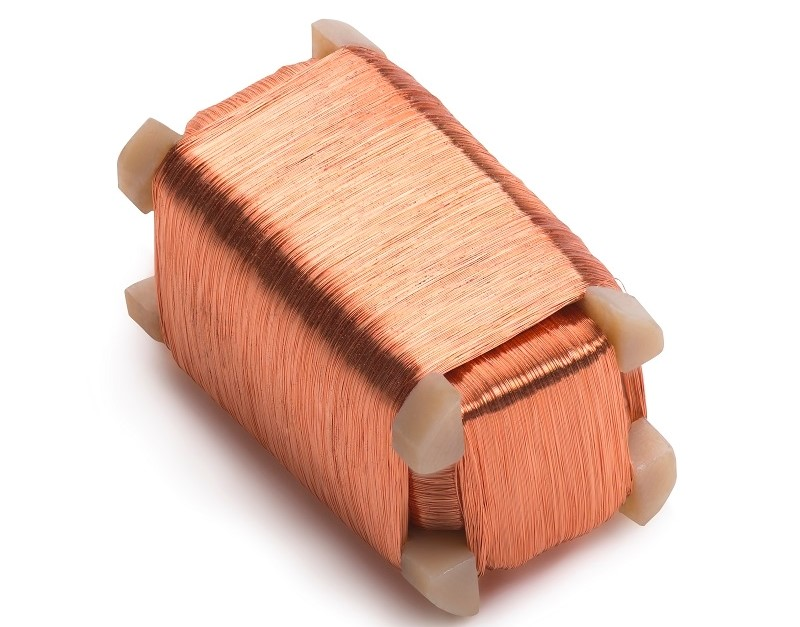

At its heart, the coil winding process is exactly what it sounds like: taking an insulated wire and winding it around a core, pin, bobbin or form to create an electromagnetic component.

You start with an electrical conductor (often copper) that’s coated with insulation.

You mount the core or form (could be a mandrel, a bobbin, or even no core for some designs) and wind the wire around it with precise geometry.

The winding geometry, number of turns, layer spacing, insulation, and overall shape will determine the coil’s electrical properties, inductance, resistance, field strength, heat generation, etc.

So when we talk about the coil winding process, we’re not just “wrapping wire” – we’re shaping a component that will function electromagnetically, and the details matter if you want reliability and good performance.

How the process works – step by step

Since you’re likely involved in specifying, managing or inspecting coil winding operations, let’s run through a typical sequence of what happens, and what you’ll want to keep an eye on:

Wire & insulation preparation

Choose the right copper (or other conductor) wire gauge, insulation material, verify that insulation quality, diameter, coating thickness are correct. As one source notes: for medical-grade micro-coils the wires may go as thin as 8 microns.

Core or form setup

Mount the bobbin, mandrel, core or pin around which you will wind. Ensure it’s secured, the spindle runs true, core dimensions are correct.

Threading & tension control

Feed the wire through guides, tensioners, ensure consistent tension. If tension is too loose you’ll get slack, crossing wires, poor fill; too tight and you risk damaging insulation.

Actual winding/layering

The winding mechanism (machine or manual) wraps the wire in the desired pattern: could be helical, orthocyclic (upper layer wires fitting in grooves of lower layer), etc. The process must maintain spacing, geometry, thickness, avoid wire contact self-touching if that’s a requirement.

Finalizing the coil

After winding the required number of turns, you cut the wire, terminate ends (solder, bond), add insulation/varnish if needed, maybe remove the core (for coreless coils) and inspect.

Quality check & application integration

Test the coil for electrical properties, insulation resistance, look for defects, and then integrate it into the device (transformer, sensor, motor, etc.)

Key considerations when specifying or managing coil winding

Here are some of the specifics you’ll want to be sure of, when working with suppliers or setting up your own process:

- Winding method & geometry: Specify whether you need orthocyclic winding (higher fill factor, better performance) or simpler helical methods depending on your application.

- Wire gauge & insulation: For a given application determine the correct wire gauge (AWG or microns) and insulation materials (temperature rating, voltage rating). As example: micro coils may require insulation for very thin wires.

- Machine capability & custom equipment: If you have ultra-fine or miniature coil requirements, you might need specialized machines – standard off-the-shelf won’t cut it.

- Tension control & winding accuracy: Machines must maintain proper tension and layering; you need to verify supplier’s quality controls.

- Post-winding finishing: Soldering/terminals, removal of core (if applicable), insulation varnish or sealing – make sure these steps are included.

- Testing & inspection: You should have specification of tests (insulation resistance, shorts, inductance, heat test) and supplier must provide QA reports.

- Integration and packaging: How the wound coils are to be handled, packaged, protected, and integrated into final assemblies matters for field reliability.

Real-world application hints

If you’re working on sensors (medical, aerospace) you may be dealing with micro-coils where size, weight, precision are critical. That means you’ll demand very fine wire (8 microns or so) and winding machines that are custom.

If you’re working on motors or transformers for industrial use you may be less extreme on micro scale but you’ll care a lot about heat dissipation, fill factor, reliability under load. Winding method (orthocyclic vs basic) becomes more important?

If you’re procuring or distributing coils, always ask: What winding method is used? What machine/automation? What QC? What specs can you see for the finished coil? At the end, the coil winding process you choose will reflect on your product quality, reliability, and cost.

Summary:

The coil winding is an essential element in the process of electromagnetic component production. Specifying, managing, distributing or designing, knowing how it works, what factors to consider, what are the risks, will you have the edge. Do not put winding together as a round of wrap on a core. Address it as an accurate engineering task.

And do that, then your coils, and your projects, work better and last longer and yield less surprises.

FAQs

How important is the winding geometry in the coil winding process?

Very important. The geometry (how the wire is layered, whether the upper layer sits in grooves of the lower, spacing between wires) influences how well the coil conducts, how it handles heat, how stable it is. For example, orthocyclic winding yields higher fill factor and better performance.

Can I just use a standard winding machine for all coils?

No. For many standard coils you may use semi-automated machines. But for specialty (micro-coils, ultra-fine wires, unusual shapes) you’ll need custom machinery, high precision control of tension, guides, wire handling.

What are the biggest risks if the coil winding process is done poorly?

If winding is done without proper control, you risk wire insulation failure, poor fill factor (so less performance), overheating, inconsistent inductance/resistance, and ultimately failure in the field. From a product perspective you’ll lose reliability and reputation.