In the world of electronics, understanding the various types of PCB pins is crucial for designing effective and reliable circuits. These small yet essential components serve as connectors that facilitate communication between different parts of a circuit board. As technology advances, so do the types and functionalities of these pins, making it important for engineers and hobbyists alike to stay informed.

From through-hole pins to surface mount options, each type offers unique advantages depending on the application. Whether it's for enhancing signal integrity or optimizing space on a compact design, knowing which pin type to use can significantly impact performance. This article explores the different types of PCB pins available and their specific uses in modern electronic designs.

What Are PCB Pins?

PCB pins are essential components that connect different elements of a printed circuit board, enabling communication and power distribution between them. They come in various types, each designed for specific applications and functionalities.

- Through-Hole Pins: Through-hole pins insert through holes in the PCB, providing strong mechanical connections. These pins suit high-stress environments due to their robust soldering capabilities.

- Surface Mount Pins: Surface mount technology (SMT) utilizes pins soldered directly onto the surface of the PCB. This method supports smaller designs and allows for higher component density.

- Pogo Pins: Pogo pins are spring-loaded connectors that provide temporary electrical connections during testing or programming phases. Their design ensures reliable contact even with minor misalignments, making them ideal for portable devices.

- Magnetic Connectors: Magnetic connectors utilize magnets to establish connections between PCBs without physical contact points, reducing wear and tear while enhancing durability.

- Header Pins: Header pins consist of multiple aligned pins used for connecting headers to sockets on a PCB. They facilitate easy plug-and-play functionality for modular designs.

Promax’s manufacturing capabilities in China focus on delivering high-quality pogo pins and other connector solutions tailored to meet specific industry needs across consumer electronics, aerospace, and medical sectors. Their expertise ensures precision engineering and adherence to stringent quality standards necessary for modern electronic applications.

Types of PCB Pins

Understanding the different types of PCB pins is essential for selecting the right connectors for specific applications. Each type has unique characteristics that suit various electronic designs.

Through-Hole Pins

Through-hole pins feature long leads inserted into holes drilled on a PCB, providing robust mechanical stability. They excel in high-stress environments due to their strong connections and resistance to vibration. These pins support soldering from both sides, enhancing durability. Applications often include power supplies and larger components where reliability is crucial.

Surface-Mount Pins

Surface-mount pins are designed for mounting directly onto the surface of PCBs, allowing for compact circuit designs. Their smaller size enables higher component density, which reduces overall board space requirements. This pin type supports automated assembly processes and enhances manufacturing efficiency. Common applications include consumer electronics where miniaturization is essential.

Edge Connector Pins

Edge connector pins align along the edge of a PCB, facilitating connections with corresponding sockets or backplanes. These connectors support easy insertion and removal, making them ideal for modular systems that require frequent updates or replacements. Applications range from computer memory modules to peripheral devices requiring reliable data transfer.

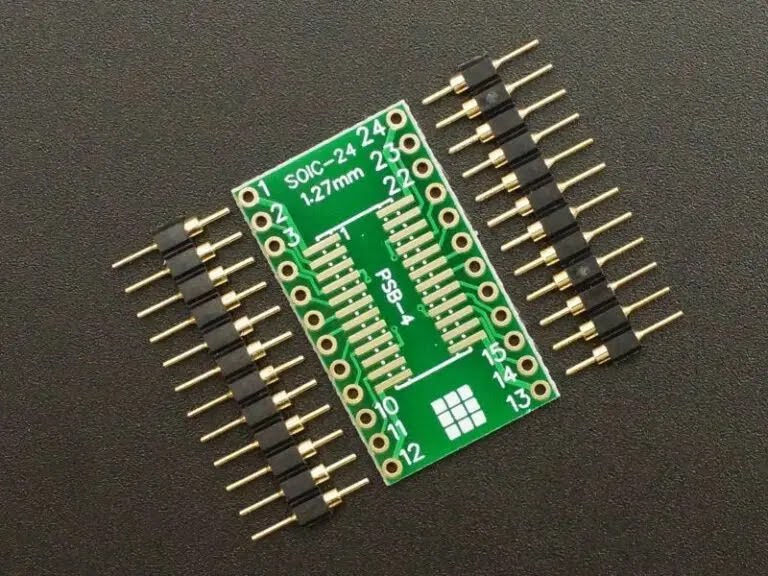

Pin Headers

Pin headers consist of multiple aligned pins used for connecting wires or other components securely. They come in various configurations, including single-row and double-row options, accommodating diverse design needs. Often found in prototyping boards and development kits, these headers allow quick connections between different circuit elements while simplifying assembly processes.

Terminal Blocks

Terminal blocks provide secure wire-to-board connections through removable screw terminals or spring clamps. They enable easy wiring changes without soldering, promoting flexibility during installation and maintenance tasks. Commonly used in industrial control systems and automation equipment, terminal blocks improve safety by preventing accidental disconnections while allowing straightforward electrical integration.

Applications of PCB Pins

PCB pins play a crucial role across multiple industries, providing reliable connections for electronic devices. Their specific designs cater to different applications, ensuring optimal performance.

Consumer Electronics

In consumer electronics, PCB pins facilitate essential functions in devices like smartphones, tablets, and laptops. Through-hole pins offer robust mechanical stability for components that experience frequent handling. Surface mount pins enable compact designs necessary for modern gadgets with limited space. Promax manufactures high-quality pogo pins that support temporary connections in testing scenarios and ensure precise alignment in assembly processes.

Automotive Industry

The automotive industry relies on durable PCB pins to connect sensors, control units, and other critical components. Pogo pins provide reliable electrical contact points while accommodating movement due to vibrations and thermal fluctuations. Header pins allow easy modular design for rapid assembly and repairs. Promax's manufacturing capabilities in China ensure adherence to quality standards required for automotive applications, delivering connectors that withstand harsh environments.

Industrial Equipment

Industrial equipment requires sturdy pin connections for power distribution and signal transmission in machinery and automation systems. Terminal blocks offer secure wire-to-board connections that withstand heavy loads and vibrations. Edge connector pins simplify integration into larger systems by facilitating quick installation or removal of boards without soldering. Promax specializes in producing connectors tailored to the industrial sector's demanding specifications, ensuring longevity and reliability under challenging conditions.

Conclusion

Understanding the various types of PCB pins is crucial for anyone involved in electronics. Each type serves a specific purpose and can significantly influence circuit performance and reliability. Engineers and hobbyists alike benefit from knowing when to use through-hole, surface mount, pogo pins, or other options based on their project needs.

As technology continues to advance, staying informed about these connectors ensures optimal design choices. With manufacturers like Promax providing high-quality solutions tailored for diverse industries, selecting the right PCB pin has never been more accessible. This knowledge not only enhances effective communication between components but also contributes to the overall success of electronic projects.