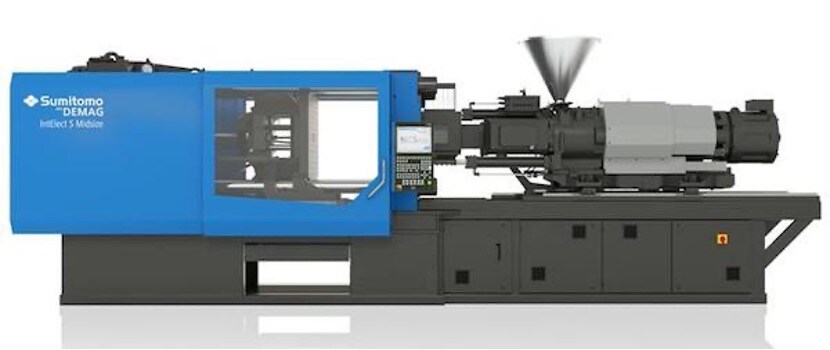

Plastic injection molding is a well-reckoned manufacturing process through which different parts can be produced with great accuracy. This process entails putting hot melt plastic in a mold, then cool and solidify to reach the intended shape. Plastic injection molding is widely adopted by various industries such as automotive, electronics and consumer products. By using highly reflective molds in rapid injection molding, production rates are significantly increased.

Selecting the appropriate plastic injection molding machine plays an important role for production especially for low volume manufacturing. Plastic injection molding machines come in various classes, each of which can meet particular manufacturing needs. Manufacturers will also be in a position to choose the right technology given the strengths of each machine so that they can produce quality parts efficiently and at lesser cost.

Types of Plastic Injection Molding Machines

1. Hydraulic Injection Molding Machines

These are the oldest and dominant type of injection machines available in the market. These machines employ the use of hydraulics to apply pressure and control the injection process. The higher clamping force is one of the important benefits of this method, which allows them to manufacture large parts. The automotive industry as well as manufacturing of heavy equipment often use hydraulic machines for making strong, high tensile structures.

Looking at cost hydraulic machines are comparatively cheaper and long lasting and they perform heavy work. However, in comparison to other machine types, they are not as energy-efficient, which over time may increase the cost of operation, particularly in high-volume production environments.

2. Electric Injection Molding Machines

These are relatively new and utilize electric motor for their functioning as opposed to combustion engines. These machines are also faster and highly accurate as compared with the other types of machines used in various projects. Electric injection machines are particularly useful in having rapid injection molding due to speed and accuracy.

3. Hybrid Injection Molding Machines

Hybrid machines are machines that have features of both hydraulic and electric injection molding machines. Hydraulic power is used where there is need of high force and electric power where there is need of precision. This combination of attributes makes hybrid machines suitable and flexible for nearly any production requirement in terms of speed, power, and power consumption. Low volume manufacturing is where hybrid machines are most commonly used since flexibility and cost per unit are both factors. Hybrid systems are a perfect fit for manufacturers, which require the power of hydraulic equipment but prefer the accuracy of electric drives.

4. Two-Shot Injection Molding Machines

Two-Shot Injection Molding Machines are useful in the manufacture of articles that are formed from two different materials or two different colors in one molding process. This technique is more common in industries that involve consumer products, electronics, and automotive engineering, where parts include different materials for different uses or looks.

Two-shot molding avoids the necessity of assembling the components later, thus making it more time efficient and less costly in terms of labor. For instance, a simple product such as a toothbrush handle might have a hard, rigid core of plastic for strength and an outer layer of rubberized soft material for comfort; all in a single cycle of manufacturing. This type of machine is also suitable for times when a product requires the use of two or more materials, which have to fuse together smoothly without the need to install glue between them.

Benefits of Plastic Injection Molding Machines

The plastic injection molding machines offer high accuracy and productivity making them useful in the manufacturing processes where precision is paramount as in the manufacturing of medical equipment, electrical devices among others. These machines generate parts of consistent quality manufactured with high tolerance, especially when it comes to intricate geometry. This is improved on by the fast bottom injection molding as it makes production of prototypes or small quantities easier hence helping the manufacturers to serve their customers or test new designs in the market.

Another advantage of injection molding is that it is highly economical for large production runs as well as for short production runs. The volume cost of molds is relatively high but once the mold is developed, the cost per part is relatively low hence suitable for large scale production. In low volume production, the efficiency and time taken to skill injection molding is low and the setting costs are low and do not affect small industries and also it has minimal wastage recipes which is essential to organizations in need of many small parts.

Injection molding machines can use several types of thermoplastics and need special mechanical or chemical properties for the parts that are manufactured. It also provides the manufacturers with all the flexibility that is required to meet various application requirements ranging from heat resistance to strength to flexibility without compromising on the quality aspect.

Also, the current injection molding machines particularly the electric and the hybrid types use low energy in the manufacturing process, hence saving energy. With the resource conservation climbing to the agenda in manufacturing, these machines assist in reduction of impacts on the environment besides achieving the aim of minimizing the costs of production.

Conclusion

Plastic injection molding machines provide various advantages such as high accuracy and productivity, flexibility in material usage, and minimal wastage. These various categories of machines help the manufacturers to buy the most suitable technology that fits their need whether they are focused on rapid injection molding for prototyping or low volume manufacturing for smaller, more customized production runs. By acquiring the proper machine, owners can improve the performance of the manufacturing line, cut costs, and deliver quality components for present industries.