It’s impossible for a car to be perfect right out of the box. Even some of the best-built vehicles on sale today are subject to recalls. The term “recall” tends to carry a negative connotation, as it identifies a fault that, for passenger cars, means a legitimate safety risk.

But it shouldn’t.

Lately, it feels like there have been a lot of recalls. Does that mean cars are getting less reliable? Or less safe? Or does it mean manufacturers are stepping up their accountability, tackling issues they wouldn’t have before?

Simple questions with complicated answers.

Have There Been More Recalls Lately?

The short answer is yes. Last year, the National Highway Traffic Safety Administration (NHTSA) released a swath of data on recalls from 2003 to 2023, showing a general upward trend in both the number of recalls and the number of vehicles recalled.

Last year was a bit of an outlier, though. In 2024, automakers issued just 445 recalls, encompassing around 29 million vehicles—a drop in both metrics versus 2023.

This year is also trending downward, at least in the number of vehicle recalls. Automakers have recalled just over 10.7 million vehicles through the first half of 2025, according to BizzyCar, a recall-focused service management system for dealerships.

The number of recalls issued in 2025 is up through the first two quarters, though, with 229 campaigns issued. That’s thanks mostly to Ford, which has issued 88 of those recalls alone, or around 36 percent. Ford products represent just over 40 percent of all vehicles recalled in 2025 so far.

But why have there been more recalls?

There are a host of reasons why the number of recalls and the amount of vehicles recalled have increased over the past 22 years. While the number of new cars sold in the US each year usually hovers between 14 and 17 million vehicles, the cars themselves have grown significantly in complexity.

Your average passenger car is far more complex than it was 20 years ago. And because cars are more complex, there’s more potential for things to go wrong. Active safety systems, adaptive suspensions, brake & steer by wire, multi-screen infotainment systems, hybrid drivetrains—these are just a few of the reasons why your car might be back in the shop shortly after it leaves the lot.

Then there’s the ever-increasing complexity of the automotive sector’s global supply chain. As environmental disposal service Valicor points out, even a small issue with a non-critical component can trigger a large-scale recall across multiple continents and different manufacturers.

Recalls have also increased due to customer expectations. Back in the 1980s, the average buyer likely expected their car to break down more often than the average buyer in 2025. Nowadays, people expect their new car to work 100 percent of the time, complexity be damned. So even if something small goes wrong, manufacturers are held to a higher standard, pushing them to issue recalls they may not have issued 30 years ago.

Similarly, regulatory bodies are expecting more than ever from manufacturers. Oversight is as stringent as it’s ever been, with the NHTSA closely monitoring incidents and complaints from buyers in order to recognize patterns and hold carmakers accountable.

Why More Recalls Are a Good Thing

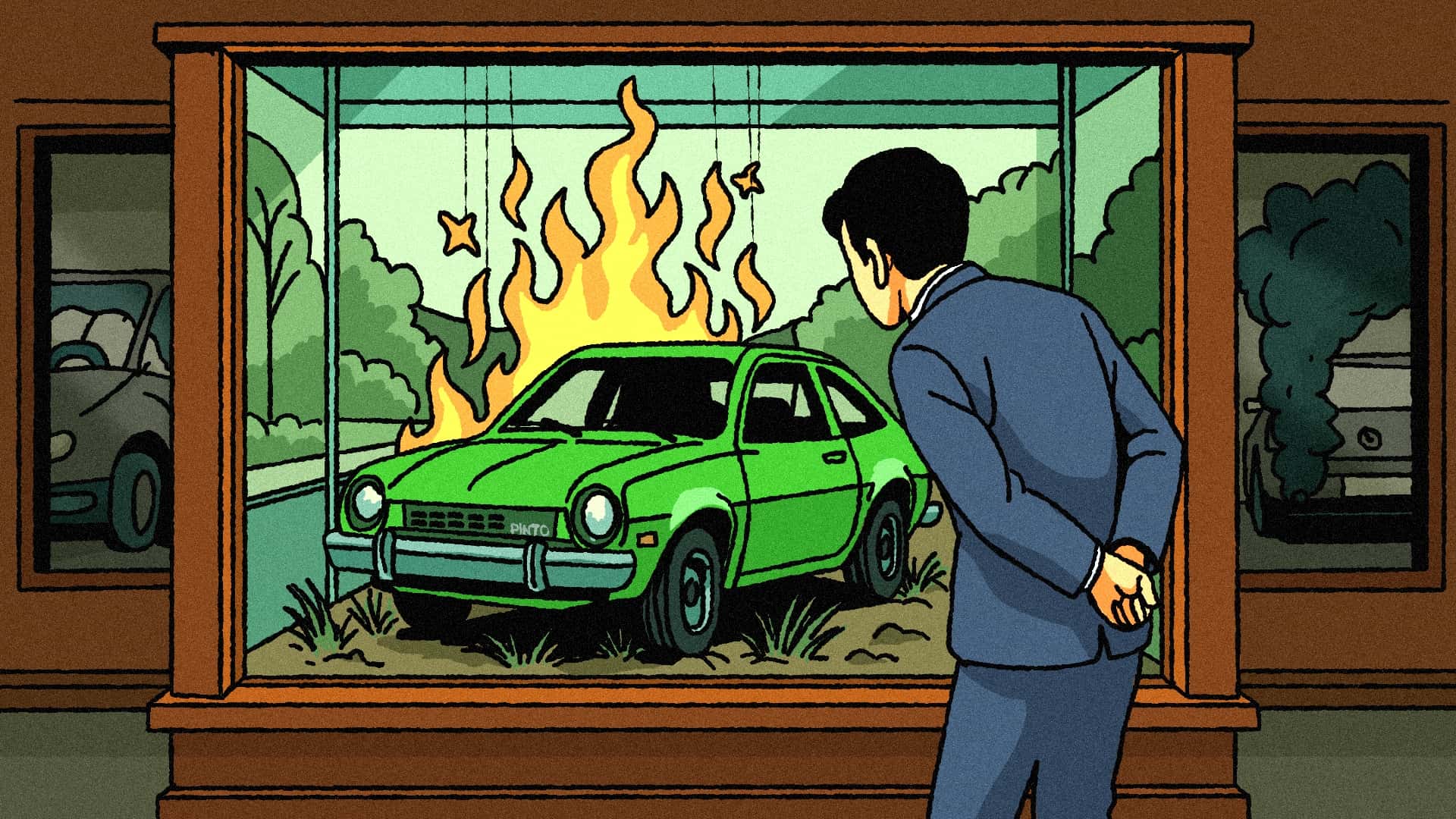

When the average person hears the words “car recall,” a few moments probably come to mind. Ford’s Pinto fire fiasco, Takata’s massive airbag debacle, GM’s ignition-switch problem, or Volkswagen’s Dieselgate scandal, just to name a few.

All of those incidents generated a ton of bad press for their respective brands. While GM has mostly escaped with its reputation unscathed, the name Takata will forever be associated with shrapnel-loaded airbags. Volkswagen, meanwhile, is still dealing with the fallout from Dieselgate 10 years later. The first Ford Pinto recall happened nearly 50 years ago. And here we are, still talking about it.

The point is, huge, headline-grabbing recalls are bad for business. They erode trust with consumers and tarnish brand image. Having witnessed all of these controversies and the resulting negative impact on their bottom lines, manufacturers across the board now take a more proactive approach to recalls and overall quality.

Still, back to my original point, no car is perfect from the get-go. There will always be issues that need fixing. But instead of waiting for problems to fester and grow into gigantic, unmanageable messes—like the issues mentioned above—carmakers have gone in the opposite direction, issuing more recalls than ever to cover their bases. So while automakers recall more cars, it’s usually for less dramatic reasons, and in smaller numbers.

Tesla, weirdly, is the best example for this. The electric carmaker recalled a staggering 5.1 million vehicles in 2024—the most of any automaker in the US. But a majority of those “recalls” were solved simply by issuing software updates over the air, without the owner having to drive to a service center (or even leave their garage).

Stomping out problems before they become destructive is great for brand reputation, but it’s also good news for the end user. Because brands are holding themselves more accountable, buyers end up with a better product. And if something does go wrong, it’s more likely the issue will be addressed quickly and properly, before it gets any worse.

Recalls Can Still Point to Bigger Issues

Car recalls carry far more reach than huge safety or emissions concerns—especially now. Recalls can mean anything from a do-not-drive order due to a leaking brake system to a simple software update. Tesla’s huge recall numbers are proof of that.

But recalls can still signal a bigger issue, even if the campaigns themselves don’t point to one specific problem. Just look at Ford. In 2023, it was among the most recalled brands in the country, with 54 recalls potentially affecting over 5.6 million vehicles. The company didn’t fare much better in 2024, recalling 4.7 million cars across 67 different campaigns.

Things are getting even worse for the American automaker in 2025. Ford has issued an incredible 94 recalls in 2025 as of this writing, potentially affecting 6.35 million vehicles. That means it’s on track to double the number of cars recalled by the end of the year. It’s also a record for the most recalls ever issued by a manufacturer in a single year—and there’s still six months to go in 2025.

There’s no one reason for the huge jump in recall numbers—the data above highlights numerous sources, ranging from electrical problems, backup camera faults, powertrain issues, and more. The sheer number of vehicles being affected is, then, indicative of a persistent quality-control issue at Ford.

The company is aware of this, of course. “I think we all have regrets and that’s a big one for me,” CEO Jim Farley said last year, highlighting his mistake not to focus on revamping the company’s development cycle to improve quality. "It needed a much more fundamental reset than I had realized."

Farley has since promised big gains in quality for Ford come 2025, though obviously, those gains haven’t materialized.

A swell of recalls doesn’t just hurt your customers. It costs money, too. Over the last three years, Ford’s given up millions in profit to cover warranty and recall repairs. The brand’s 90th recall, a fix for a fuel injector problem on Bronco Sports and Escapes, is estimated to cost the company over half a billion dollars, according to Reuters. Nine-figure mistakes like this aren’t sustainable.

Our advice? Look to rival Volkswagen. In 2022, it was the second-most recalled brand in the country, with over 1 million vehicles recalled. The next year, it had recalled just 332,000 cars, dropping all the way to 18th place.

"Volkswagen Group of America has been working diligently to improve the quality of its vehicles, which in turn reduces the potential for recalls,” the company told Motor1 back in 2023. “Recently, quality problems have been reduced significantly, warranty claims are at a historical low and our regional Quality Testing and Validation program is showing positive results."

The lesson here, then, is not to fret too much when cars get recalled. Usually, it’s a sign that manufacturers are on top of things, rather than panicking to fix defects.