The power supply unit (PSU) is the most important part of every electronic device, including, of course, computers. It is the heart of your system since it feeds energy to the other components. Consequently, if the PSU fails, everything else fails with it. This is the reason most experienced technicians start a failure investigation from the PSU before proceeding to the rest of the components. And, consequently, this is why you should pay extra attention to your choice of PSU and not make a decision based exclusively on price. After all, a good PSU will do its job for quite a long time, far outlasting the rest of your expensive system components.

To properly review a PSU, expensive equipment is required, and the reviewer needs to know not only how to operate it, but also have sufficient knowledge about electronics and a PSU's design. The knowledge part is especially crucial since not even the most expensive equipment can make a good PSU review if the reviewer doesn't know how to properly use it and what tests to conduct with it.

In our reviews, we examine the PSU's performance, noise, and temperature ratings, along with the build quality of the units. We also judge the PSU's individual components, cables, connectors, and even product specifications and packaging while providing a performance per dollar comparison.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

Effective PSU evaluation requires specialized equipment and controlled procedures, far beyond basic multimeters and ad-hoc load tests. The setup used incorporates programmable electronic loads, precision oscilloscopes, power analyzers, thermal/acoustic instrumentation, and custom fixtures of our own design to ensure repeatable and standards-compliant results.

Electronic Loads

Two high-precision Maynuo M9714 (1200 W) and two Maynuo M9711 (150 W) programmable DC loads are used. This configuration allows up to 2400 W to be drawn from the +12 V rails and 150 W from each of the +3.3 V and +5 V rails. Their fast response enables both static and transient load testing. We also have two Vantec CA5015 loads (150W each) for secondary tests (e.g. 5VSB checks, etc).

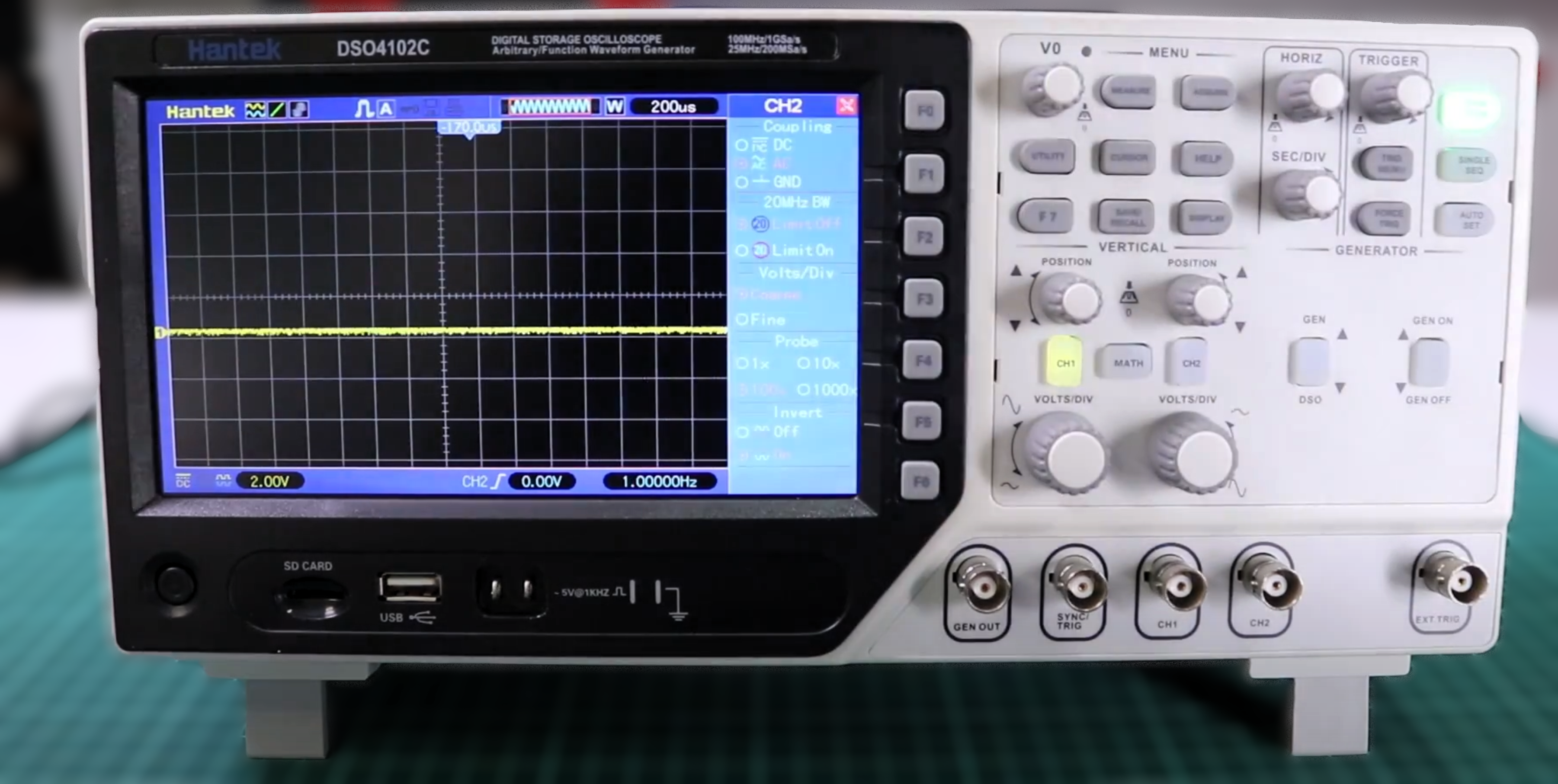

Oscilloscope

A Hantek DSO4102S is used, with a maximum bandwidth of 100 MHz and digital acquisition capabilities.

A Rigol DS5042M digital oscilloscope is also employed, featuring 40 MHz bandwidth and a 500 MSa/s real-time sampling rate. Both are suitable for ripple and noise testing as per the ATX design guide.

Power Measurement

Input power is monitored with an Extech 380803 power analyzer, which provides true RMS readings and accounts for harmonic distortion generated by switching PSUs. The AC input is regulated via a 3000 VA VARIAC, maintaining precise 230 V/50 Hz conditions. We also test the units at 115 V/50 Hz. At present, 110 V/60 Hz testing is not supported due to the absence of a high-output programmable AC source.

Thermal Monitoring

Thermal performance is tracked using UNI-T UT-325 digital thermometers with four probes: ambient air, PSU exhaust, and primary/secondary heatsinks. This allows detailed temperature mapping under different operating conditions.

Acoustic Testing

Fan speed is recorded with a laser tachometer, while acoustic output is measured using an Extech HD600 sound level meter. Since active load equipment generates noise, acoustic testing is performed separately with the PSU fan powered by a custom fanless DC power supply. Noise is correlated against RPM data, with a measurement environment baseline of ~30.4 dB(A).

Environmental Simulation

A custom-built hot box simulates in-case thermal conditions. It consists of a closed chamber with a controlled air-heating element, managed via a DAQ and software. Tests are performed at both room temperature (~25 °C) and elevated hot box conditions (45–50 °C) to evaluate efficiency and stability under realistic system thermals.

Test Procedures

All testing follows Intel’s ATX Design Guide and the Generalized Test Protocol for Internal AC-DC and DC-DC Power Supplies, ensuring standardized methodology. Where guidelines are insufficient (e.g., transient and cross-load testing), custom procedures are applied, such as loading rails independently to simulate demanding scenarios. Efficiency is tested from 5% to 100% load, exceeding the standard 20%–100% certification points to reflect modern idle power behavior.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

A PSU should be able to keep all of its rails within some predefined voltage ranges at all cases/loads. In Table 1, you will find these ranges (following the ATX v2.53 specification). With the introduction of ATX v3.0, there are some differences in load regulation since the new standard allows for higher voltage drops at +12V, up to 7% on all connectors but PCIe ones, where the voltage drop can go up to 8%.

DC Output Voltage Regulation

Voltage Name |

Range |

Minimum |

Nominal |

Maximum |

|---|---|---|---|---|

+12V1 |

±5% |

11.40V |

12.00V |

12.60V |

+12V2 |

±5% |

11.40V |

12.00V |

12.60V |

5V |

±5% |

4.75V |

5.00V |

5.25V |

3.3V |

±5% |

3.14V |

3.30V |

3.47V |

-12V |

±10% |

-10.80V |

-12.00V |

-13.20V |

+5VSB |

±5% |

4.75V |

5.00V |

5.25V |

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

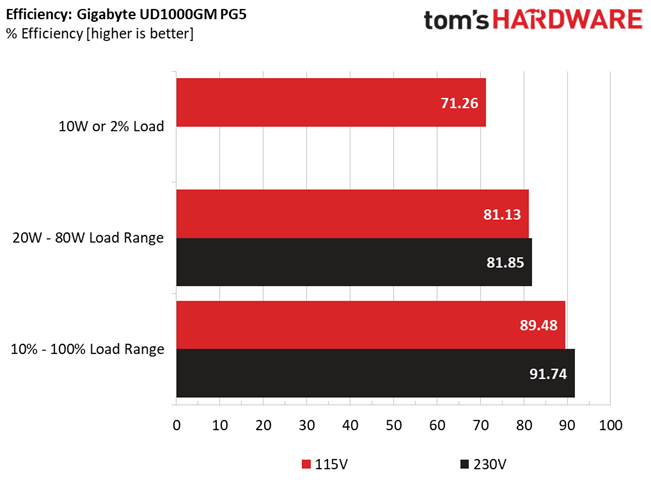

The 80 PLUS certification measures efficiency at 20%, 50%, and 100% load of the PSU's maximum-rated capacity, up to the Gold efficiency certification. For the Platinum and Titanium levels, efficiency is also measured at 10 percent of the PSU's maximum-rated capacity load.

Simply put, if a PSU has an 80 PLUS certification, then it must have the equivalent efficiency required by the corresponding certification. However, 80 PLUS measures at a mere 23 °C (73.4 °F) ambient, whereas we measure efficiency at a higher ambient temperature. This means that, in many cases, a PSU that is certified to a certain efficiency category fails to deliver the same efficiency at higher temperatures in our tests.

Besides the 80 PLUS standard, there is also the Cybenetics efficiency and noise measurements standard, which tests with more than 1450 different load combinations at higher temperatures (30 °C ± 2 °C) for more accurate results. Cybenetics has evaluated more than 1,000 PSUs to date, providing comprehensive evaluation reports on its database.

A third certification body, the PPLP (originally marketed as the “PSU Performance Level Plan” and recently rebranded as the Pro Performance Level Plan), is an independent evaluation laboratory and star-rating scheme that issues model-level Efficiency ratings for power supplies, as well as complementary Silent (acoustic) and component-efficiency star ratings. PPLP publishes full per-model test reports and applies segmented, scenario-based evaluations (medium/heavy/extreme load profiles) for acoustic ratings using equivalent continuous sound level (LAeq), and it has expanded its scope to include DC-axial fan and case-cooling efficiency star standards; PPLP’s reports and sample-management procedures are intended to support repeatability and OEM certification workflows.

Feature |

80 PLUS |

Cybenetics (ETA / LAMBDA) |

PPLP (Pro Performance Level Plan) |

|---|---|---|---|

Testing organisation |

CLEAResult (80 PLUS program operator). (CLEAResult) |

Cybenetics Labs (independent testing + public database). (Cybenetics) |

PPLP Lab / Pro Performance Level Plan (operated by PPLP Lab / Guangzhou Chaoneng Tech Service Co., Ltd.). (pplp.info) |

Load points / scope |

Fixed set points (typically 20%, 50%, 100% of rated output; 10% included for Platinum/Titanium variants per program rules). |

Comprehensive multi-rail/load mapping — results derived from >1,450 tested load combinations with interpolation to many more data points. |

Programmatic star ratings across operational ranges; tests and reports are scenario/segment-based (includes acoustic segmented-load tests and electrical performance reporting per model). |

Ambient / thermal conditions |

Standardized chamber temperature: 23 °C ±5 °C per 80 PLUS test protocol. |

Evaluations conducted in higher ambient conditions (≈30 °C ±2 °C) to better represent in-chassis operation. |

Emphasises representative, in-system conditions (thermal simulation inside chassis and controlled acoustic/thermal environments are described in PPLP reports). |

Noise / acoustic evaluation |

Not part of core 80 PLUS efficiency certification (efficiency only). |

Includes LAMBDA (noise) ratings and quantifies average noise over many load combinations. |

Provides a dedicated “Silent Star” acoustic rating using LAeq across medium/heavy/extreme load scenarios; results reported per model. |

Reporting & database |

Certificate listings and model database on 80 PLUS site; limited per-model public test data beyond certification entries. (CLEAResult) |

Public database with detailed per-model test pages (efficiency, noise, PF, ripple, etc.). (Cybenetics) |

Publishes full model test reports and star ratings on pplp.info; offers efficiency, acoustic and component (fan/case) reports. (pplp.info) |

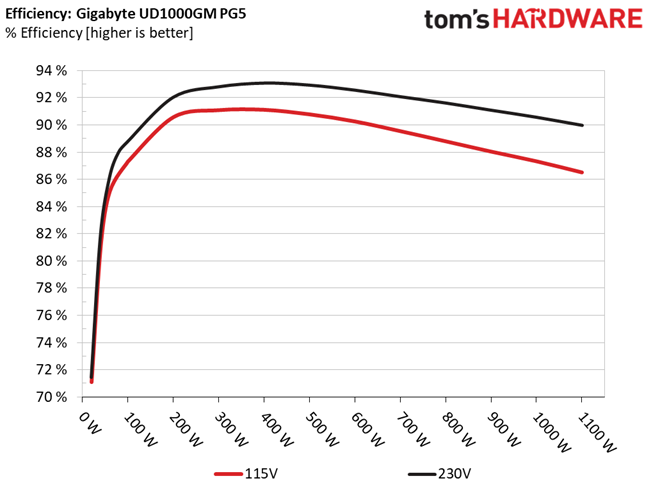

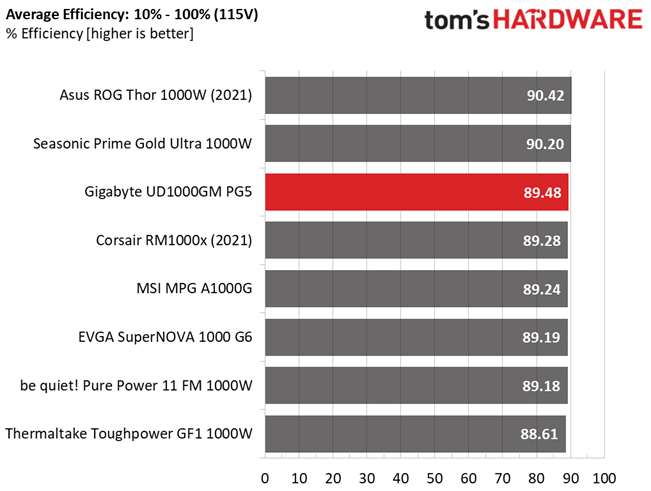

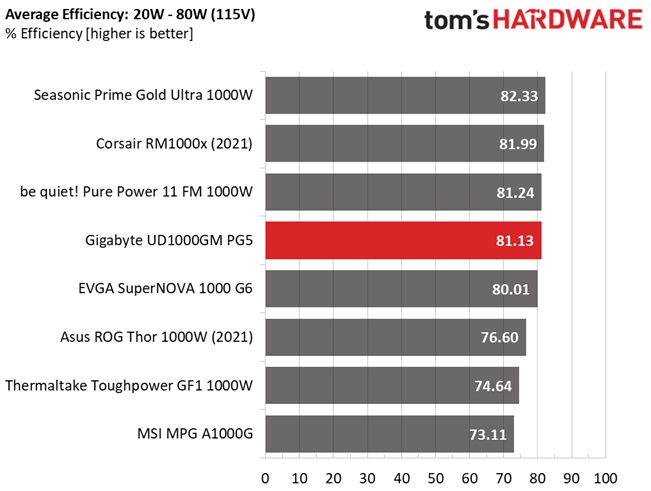

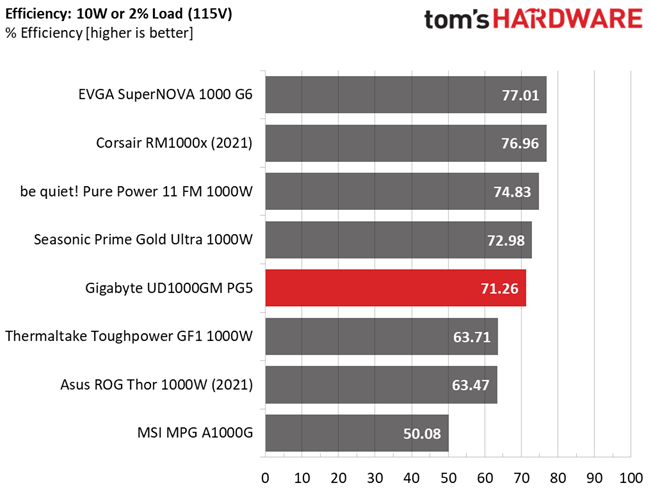

In our reviews, we measure efficiency with a super light load of 5% of the PSU's max-rated capacity, and along its nominal loading range of (10%-100%) in steps of 10%. We calculate average efficiency as the average between 10% and 100% loading. Efficiency is tested both in room temperature and in hotbox temperature conditions.

The ATX specification also states that the efficiency of the 5VSB rail should be measured, too. In the table below, you will find the minimum 5VSB efficiency levels that the ATX specification recommends.

Recommended System DC And AC Power Consumption

Load |

Efficiency |

|---|---|

≤0.225W |

< 0.5W to meet 2013 ErP Lot 6 requirement (100V~240V) |

≤0.45W |

< 1W to meet ErP Lot 6 requirement (100V~240V) |

≤2.75W |

< 5W to meet 2014 ErP Lot 3 requirement (100V~240V) |

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

Ripple represents the AC fluctuations (periodic) and noise (random) found in the DC rails of a PSU. Ripple significantly decreases the life span of capacitors since it increases their temperature; a 10 °C increase can cut into a capacitor's life span by 50 percent. Ripple also plays an important role in overall system stability, especially when it is overclocked.

The ripple limits, according to the ATX specification, are 120mV for the +12V and -12V rails, and 50mV for the remaining rails (5V, 3.3V, and 5VSB). Nonetheless, in modern PSUs, we expect to find a much lower ripple. It should be just a small fraction in high-end platforms with quality components and the proper amount of filtering capacitors.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

In practical operation, a PSU is constantly subjected to changing loads, depending on the activity of the CPU, GPU, and other system components. To properly evaluate performance under such conditions, our reviews include transient load testing.

Our procedure is as follows: while the PSU operates at a steady 20% and 50% load, we apply a transient load of 10 A at +12 V, 5 A at +5 V, and 5 A at +3.3 V for 200 ms. Each test is repeated 50 times at a rate of 5 Hz. This allows us to observe how well the unit can maintain regulation under sudden load fluctuations.

During testing, we measure the voltage drops caused by the load changes, verifying that all outputs remain within the ATX specification limits. It should be noted that the ATX v3.0 specification introduces far stricter requirements for transient response testing. However, these tests demand extremely fast and precise equipment, and our current oscilloscopes and electronic loads are not capable of fully meeting the ATX v3.0 timing criteria.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

Cross-load tests are the real deal since they show a PSU's performance throughout its entire operating range. There are no guidelines on how transient tests should be performed and the momentary power-up cross load testing that Intel recommends is far too lenient. Intel recommends that the 12 V line should be loaded to < 0.1 A and the 3.3 V / 5 V lines up to just 5 A. We perform two cross load tests of our own devise: In test CL1, we load the 12 V line up to 80% of its maximum capacity and the 3.3 V / 5 V lines with 2 A each. In test CL2, we load the 12 V line with 2 A and the 3.3 V / 5 V lines up to 80% of their maximum combined capacity. For these tests, we test at ≈45 °C (113 °F) ambient.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

Noise measurements cannot be taken during load testing because the electronic loads and other equipment generate significant background noise. To overcome this, a non-intrusive laser tachometer is used to record the PSU fan’s RPM during operation. For acoustic measurements, the PSU is then tested separately, with the fan powered by a custom-built fanless adjustable DC PSU. Noise levels are measured across the fan’s RPM range using an Extech HD600 sound level meter, and results are cross-referenced with the tachometer data.

The testing environment has a background noise floor of ~30.4 dB(A), with equipment noise becoming noticeable above 33.5 dB(A). This setup allows accurate measurement of fan noise but does not capture coil whine, as the PSU is not powered during acoustic testing. However, coil whine is noted subjectively during live load tests.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

All power supplies have to be equipped with various protections, which also includes the system that is fed with power. You can learn more about PSU protections if you read the corresponding section of our PSUs 101 article.

The most important protections are the following:

- Over Current Protection (OCP): The single +12V rail PSUs usually don't have OCP on this rail, but they should have OCP on the minor rails, including 5VSB.

- Over Power Protection (OPP): Unfortunately, most PSUs have a significantly higher OPP triggering point set than their nominal max power output. This is mainly done to deal with load spikes, which could trigger OPP and shut down the system, but OPP is there for a reason, and it has to be configured correctly to serve its purpose.

- Over Temperature Protection (OTP): Since the ATX spec recommends at least 50 °C operating temperature for continuous full-power delivery, a PSU has to have an appropriate OTP triggering point if equipped with OTP. In PSUs with only a 40 °C rating, OTP's triggering point will inevitably be lower.

- Over/Under Voltage Protection (OVP/UVP): These protections only kick in when voltages surpass or go below a specific level. Given that the corresponding ATX limits are practically dangerous for the system's health and the fact that there is no safe way to test these protections, we decided not to deal with them, for the moment at least.

- Short Circuit Protection (SCP): This is essential protection that all PSUs should have. If there is a short circuit in any rails, the PSU must immediately shut down.

- Power Good Signal (PWR_OK): This signal has to drop when any of the +12V, 5V, or 3.3V output voltages go out of spec.

- No-load Operation (NLO): The PSU must operate normally even when no load is on its outputs.

- Surge and Inrush Protection (SIP): The design must include a Metal Oxide Varistor (MOV) or a Transient Voltage Suppression (TVS) diode, both of which protect against voltage spikes coming from the mains network. In addition, the platform must be equipped with inrush current protection. The most common way of lowering the inrush current during the PSU's start-up phase is by using an NTC (Negative Temperature Coefficient) thermistor and a bypass relay, which allows the thermistor fast cool down.

Please note that a PSU might be able to deliver much more than its nominal power under normal ambient temperatures, but at higher temperatures, this won’t be the case, and if OPP is set too high then most likely the PSU will be destroyed, especially if OTP is absent. In addition, if we notice any load regulation or ripple suppression issues during our OPP tests, we consider this protection to be improperly configured.

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums

This article described the necessary equipment needed for a proper PSU review and outlined our testing methodology, including a wide variety of tests. As you have probably noticed, PSU reviewing is a complex, time-consuming, and expensive task. Even if you possess all of the necessary tools, you need to have the proper electronics background so that you can dismantle the PSUs without damaging them or harming yourself. You also need to provide an accurate analysis of the PSU's platform and its components to judge its build quality. PSU reviewing is a hard job, but someone has to do it, and, thankfully, we enjoy the work!

MORE: Best Power Supplies

MORE: All Power Supply Articles

MORE: Power Supplies in the Forums