Green Corridors International Inc. announces the launch of Project Pegasi, a novel intelligent freight transportation system designed to operate between inland terminals in Monterrey, Mexico, and Laredo, Texas. The system introduces a dedicated guideway for automated shuttles transporting 53-foot trailers, creating a terminal-to-terminal connection intended for congested short-haul freight corridors.

It currently holds a U.S. presidential permit allowing the structure to cross the border and interface with federal agencies, including the U.S. Department of Transportation and U.S. Customs and Border Protection. On the Mexican side, the company is progressing through the final stages of a multi-year regulatory process.

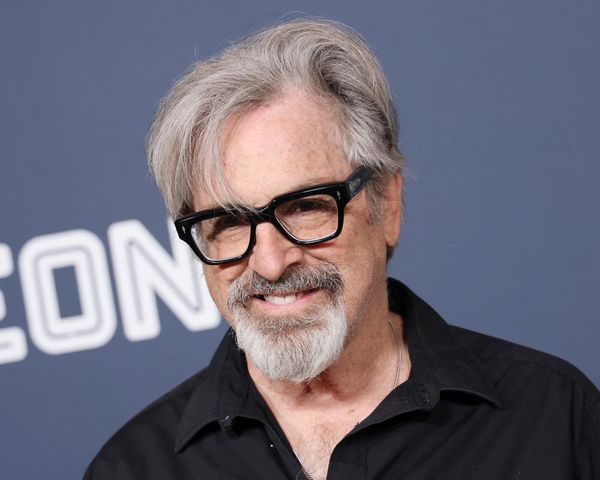

The company describes Pegasi as a closed-loop elevated machine built specifically for freight-dense regions rather than for long-haul rail or typical over-the-road transportation. The project represents the next stage of a concept originally conceptualized years earlier within a Texas research institute, later restructured and advanced under CEO Mitch Carlson. "This is a purpose-built system for corridors that experience constant pressure," Carlson said. "The design is not about replacing anything that exists today. It's about offering an additional pathway where freight demand has outgrown available capacity."

Green Corridors' initial deployment focuses on the Monterrey–Laredo corridor. The system's operating range, roughly 50 to 200 miles between terminals, was selected to align with short-distance, high-volume freight patterns that, according to Carlson, often face delays, variable border conditions, and substantial security risks. By placing terminals inland rather than at the border itself, Project Pegasi aims to streamline the process through pre-clearance scanning, coordinated handoffs, and continuous operations. "We are able to give shippers a precise handoff time many hours in advance," Carlson said. "That predictability is important for planning."

According to Carlson, security and safety are central features of the system's design. The elevated guideway removes at-grade crossings. Trailers are positioned with their doors directly against the shuttle frames, in addition to the shuttle having doors themselves, reducing opportunities for tampering while moving between terminals. Continuous camera coverage and planned AI-supported anomaly detection contribute to corridor oversight. "Security is always top of mind," Carlson said. "Everything is monitored, from the terminals to the guideway itself."

Efficiency within the terminals is another focal point, where much of the system's value is realized. The process coordinates with the truckers, truck drop-offs and pickups, dwell placement, and shuttle loading with energy-efficient shuttles powered by a combination of Tier 4 diesel generators and battery packs driving high-efficiency electric motors. Within terminals, the system relies on battery power for shorter movements, eliminating the need for engine starts during repositioning. "A lot of the operational throughput capacity happens inside the terminals. That's where the design really matters," he said.

Pegasi also aims to incorporate an environmental upside. By transitioning part of the current market onto energy-efficient automated shuttles, the project anticipates a 75% decrease in emissions between Monterrey and Laredo. Carlson explains that the system remains commercially focused. "Environmental benefits are part of the equation, but the primary goal is to solve real operational challenges," he said.

The elevated guideway is planned to align with existing public rights-of-way where feasible, limiting the need to develop new pathways through rural land. Terminal placement and inbound/outbound routing are being coordinated with transportation authorities to support local traffic patterns and highway access.

Construction of the project is targeted for 2028, with active work underway on design, digital twins, simulation, and software. Carlson notes that the effort requires sustained commitment. "We understand the scale of what we are building," Carlson said. "The only way to approach it is with an extreme work ethic, clear understanding of current operations, and substantial planning efforts."