- Ford created a Silicon Valley-style skunkworks to escape Detroit inertia and radically speed up EV development.

- Legacy EVs on modified gas platforms failed; Ford now bets on a bespoke EV platform and Tesla-like manufacturing.

- Policy shifts and slow timelines make Ford’s EV reboot a high-stakes gamble as China and Tesla continue to move faster.

No American automaker has been more vocal about the storm that's coming than Ford Motor Company. For the past few years, its CEO and other executives have taken to podcasts, TV hits, panels and interviews to stress the threat that electric-vehicle upstarts like Tesla, and the whole Chinese auto industry, present to the future of its business. Their message has been clear: if Ford loses out to China Inc.'s ability to make great, affordable EVs, "we do not have a future [at] Ford," as CEO Jim Farley put it.

But that feels rather incongruent with Ford's announcements yesterday.

The Dearborn-based carmaker is ending production of the current electric Ford F-150 Lightning, canceling plans to make another one, building a gas engine-equipped range-extender version of the next Lightning instead, killing plans for an electric commercial van, and even renaming its Tennessee Electric Vehicle Center factory to be the Tennessee Truck Plant. Ford said that EV sales and demand didn't match its projections, and that its current crop of models is not built to be profitable, so it has to retrench.

It feels like a white flag to China and the EV race. But Ford officials are adamant that the electric future now rests on a “skunkworks” project that aims to make affordable EVs in America, starting with a $30,000 pickup truck. More variants will follow, all with excellent range and entry-level prices, Ford claims.

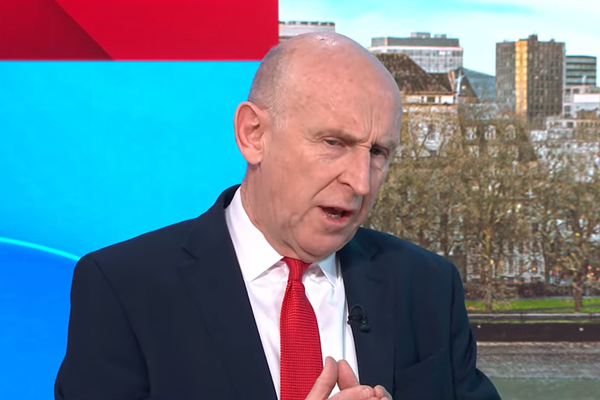

"We are focusing our EV development on our new low-cost, Universal Electric Vehicle platform," Ford executive Andrew Frick said on a call with reporters yesterday. "That's where a lot of our scaling and our growth will come from."

A lot was riding on that platform before. Now, it's shaping up to be make-or-break for Ford's future.

But Ford says that one upside that the project is driven by a former executive who knew both the old ways of the car industry and the new tech and software-focused approach to run it.

Why Ford Needed A Skunkworks Project

Doug Field worked as a development engineer for Ford in the late 1980s and early 1990s, before eventually moving on to become CTO at Segway. He then worked for Apple for five years, then spent another five years at Tesla before returning to Apple for another three-year stint. Since 2021, he’s been with Ford and today is in charge of the manufacturer’s skunkworks EV arm.

This division was created in California specifically to avoid Detroit’s bureaucracy and way of doing things in the hopes that a fresh approach would give Ford an edge. The project is a reworking of the entire assembly line process to match BYD's production costs in Mexico, something Farley has said probably wouldn't have been possible with the legacy playbook.

Ultimately, the goal is to develop EVs more like tech products than cars, drawing on Field’s unique background blending both industries.

In a recent New York Times profile, Field said he knows it’s a challenge to “try and change the course of a large organization.” However, “Silicon Valley is here because of the freedom to innovate,” concluding that “Getting a large company to be able to still produce high volume and high quality, and be able to innovate, that would be a force to be reckoned with.”

The result is a project so secretive that other Ford employees aren't even allowed inside the building, for fear of corporate meddling.

Ford also wanted to accelerate the development of its electric models and reduce the time it takes to bring one from idea to market from up to seven years to three or four years. That would be closer to how quickly Chinese carmakers can bring out new cars. No wonder, then, that Ford has started working with Renault in Europe. The French automaker claims it developed the new Twingo E-Tech electric city car in 100 weeks, or under two years. Renault's platform will underpin at least two subcompact EVs in Europe.

Faster, Cheaper, Better—Or Else

It’s not just Ford that has figured out that five to seven years is way too long for a car to stay in development these days. The key to speeding up development is having a software-defined vehicle platform that can be reused in multiple models without the need to develop it every time.

With the upcoming Universal EV Platform and a new production system, Ford wants to “deliver a new generation of affordable electric vehicles at scale.”

Vehicles built on this new platform will first roll out of its revamped Louisville, Kentucky facility after a $2 billion investment, marking the biggest change ever for the manufacturer that invented the rolling assembly line that has been the industry standard for over a century.

Other carmakers have also abandoned the traditional assembly line. Tesla, for instance, revealed its “Unboxed” production method, which has multiple parallel and modular production lines allowing multiple big parts of the car to be assembled at the same time before coming together. This leverages Tesla’s use of large cast pieces of the vehicle’s shell, structural battery packs, and makes the entire assembly process quicker and more efficient, according to the manufacturer.

Ford also needs its new EVs to be cheaper than before if it is to even stand a chance on the global stage, where China is increasingly asserting its automotive dominance and expanding its presence, especially when it comes to electric and electrified vehicles.

Whiplash At Home

At the same time, Ford is having to adapt to a new reality in the U.S., where President Donald Trump is doing away with fuel efficiency standards and slowing down the transition to electric power, pointing to lowering consumer demand for plug-in vehicles. EV tax credits are out, tariffs are in, and Ford's EV profitability headaches are now unable to bear.

On yesterday's call, executive Frick admitted that recent developments helped derail Ford's previous plans. "Some of the original forecasts had EV adoption around 45% (by 2030)," he said. "We know that hasn't been the case for several reasons: changes in the regulatory environment, commercial and consumer tax incentives, battery costs not coming down, all of which just changes the impact on overall profitability." This latest EV strategy change was clearly not planned, and Ford is taking a huge financial hit as it shifts its focus back to combustion power.

(Asked how Ford might handle more regulatory changes in a post-Trump world after Monday's pivot, a spokesperson told InsideEVs: "We have demonstrated a history of being nimble and proactive in adjusting to market realities. We continue to apply this agility in adapting to market conditions.")

But executives say they are optimistic about the EREV F-150 Lightning, which they claim will deliver more than 700 miles of total range and much longer-distance towing than its all-electric predecessor. And clearly, Ford knows that the vast majority of orders for the upcoming Scout electric trucks are for the Harvester extended-range models, so they know where truck demand is going.

But all of this proves the old Detroit way of doing things doesn’t work anymore. The fact that Ford needed to create the skunkworks division, which operates with a very large degree of freedom and separation from the main company and is shrouded in secrecy even within the company, is basically the automaker admitting it has failed. It's a Hail Mary effort to start fresh and hopefully become a big player again on the global stage.

If Ford can keep all the promises it’s made about the upcoming electric pickup built on the new platform, it may stand a chance. But Ford has made promises and then retreated from them before. The skunkworks EV truck is not even due out until 2027. By then, the industry will have moved to a new and potentially unexpected place, leaving Ford playing catch-up—again. If it even has the time and money to try this time.

Additional reporting by Patrick George.