Manufacturing today looks very different than it did just a decade ago. From automotive to aerospace, industries are under constant pressure to produce more, faster, and with higher quality. Traditional welding techniques—though reliable—often fall short when it comes to precision, energy efficiency, and automation. This is where laser welding systems are stepping in to redefine what’s possible.

By offering accuracy down to a fraction of a millimeter, cleaner welds, and faster production cycles, laser technology is no longer a niche option—it’s becoming a cornerstone of modern manufacturing. For companies looking to stay competitive, understanding the advantages, limitations, and future trends of this technology is essential.

Precision, Speed, and Clean Quality

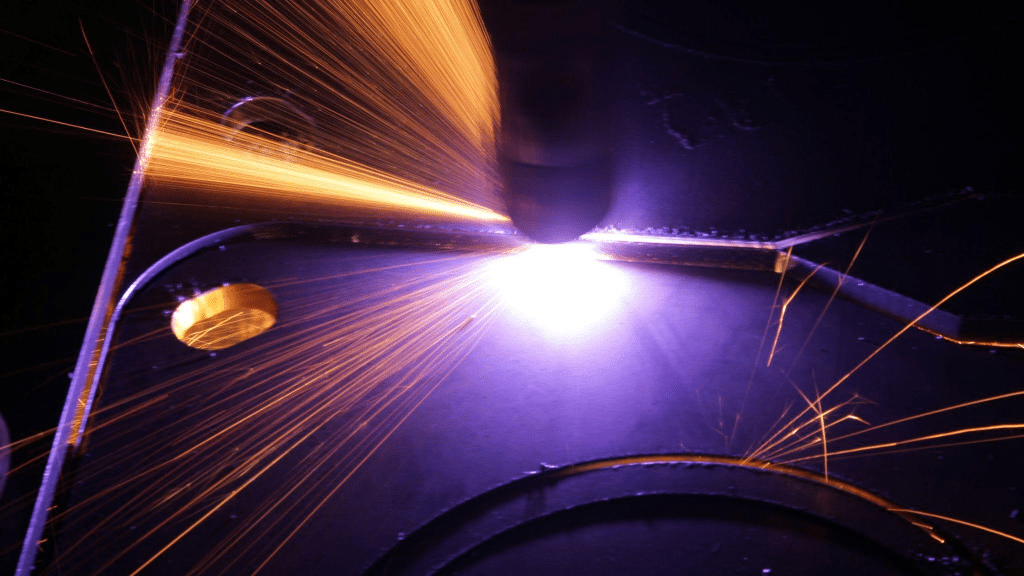

Laser welding is valued most for its pinpoint accuracy. The concentrated laser beam creates narrow, deep welds with minimal heat-affected zones. This drastically reduces distortion, which is a common issue in conventional methods.

Key benefits include:

- Minimal distortion: Protects material integrity and reduces costly rework.

- Cosmetic quality: Weld joints often emerge smooth and polished, requiring little or no finishing.

- Faster throughput: Welding speeds are 4–5× faster than MIG or TIG welding, dramatically cutting down production cycles.

For industries like medical devices or consumer electronics, where precision and clean aesthetics are critical, these advantages are game-changing.

Efficiency, Sustainability, and Cost Savings

Beyond speed and precision, laser welding contributes to a leaner, greener production process.

- Energy efficiency: Modern fiber lasers consume significantly less energy than older arc-based systems.

- Reduced waste: Precision reduces scrap and minimizes the need for rework.

- Lower long-term costs: Many manufacturers report achieving ROI within a year, thanks to lower labor costs, material savings, and reduced downtime.

In a world where both sustainability and profitability matter, laser systems align with both goals.

Automation, Monitoring & Smart Integration

One of the biggest advantages of laser welding systems is how well they integrate into automated production lines.

- CNC & robotics: Lasers can run 24/7 with minimal human intervention, increasing productivity.

- Real-time monitoring: Smart sensors and cameras monitor weld quality in real time, adjusting parameters to avoid defects.

This fusion of automation and precision makes laser welding a key enabler of Industry 4.0, where connected systems optimize themselves for peak efficiency.

Versatility & Wide-Ranging Applications

Laser welding isn’t confined to just metals. It’s compatible with:

- Stainless steel, aluminum, and titanium in aerospace and automotive.

- Polymers and thermoplastics in electronics and consumer goods.

- Medical devices and jewelry requiring microscopic precision.

Since it’s a non-contact process, there’s no electrode wear, and lasers can reach tight, hard-to-access areas where conventional welding can’t.

Challenges & Adoption Considerations

Like any advanced technology, laser welding comes with challenges that manufacturers must evaluate.

- Upfront investment: Equipment is expensive, especially for high-power or automated setups.

- Complex operation: Skilled technicians are needed to manage beam alignment, optics, and parameters.

- Safety requirements: High-energy lasers demand protective enclosures, ventilation, and strict protocols to ensure worker safety.

These factors mean that adopting laser welding requires careful planning—but the long-term benefits often outweigh the initial hurdles.

Future Trends & Technological Innovations

Laser welding is not standing still. Several innovations are shaping its future:

- Fiber lasers: Offering higher efficiency and deeper penetration for demanding applications.

- Hybrid laser-arc welding: Combines the precision of lasers with the depth of arc welding, solving limitations of both.

- AI-powered monitoring: Predictive maintenance and adaptive control are pushing weld quality assurance to new levels.

As manufacturers look to digitize and automate further, these innovations — championed by forward-thinking providers like Denaliweld — position laser welding as a central pillar of smart manufacturing.

Conclusion

Laser welding systems are revolutionizing manufacturing by combining precision, speed, efficiency, and sustainability. While the upfront costs and technical complexity present challenges, the long-term payoff is significant—especially for industries where quality and throughput are non-negotiable.

For businesses exploring advanced solutions, investing in the right system can be the difference between keeping up with competitors and leading the market. Explore our laser welding systems to see how this technology can elevate your manufacturing process.

.png?w=600)