The overmolding process is a manufacturing technology that is useful in improving product functionality and beauty by blending different materials. This process is extremely useful in various manufacturing industries like consumer items, electronics, and medical devices.

There is a detailed discussion of the process, uses of overmolding in plastic and metal below in the article. Moreover, the role of overmolding in rapid prototyping and rapid product development is also mentioned.

What is Overmolding?

It is a method used for manufacturing and one material is molded to create another component. This process is based on two steps, the first is about molding a base material and the second is about putting the substance over the first. Moreover, the end product benefits from the features of both materials. it provides better grip, insulation and beauty to the final product.

Overmolding Process

Following are the steps involved in this process:

- The first step is to prepare a base component using different materials including plastics and metals.

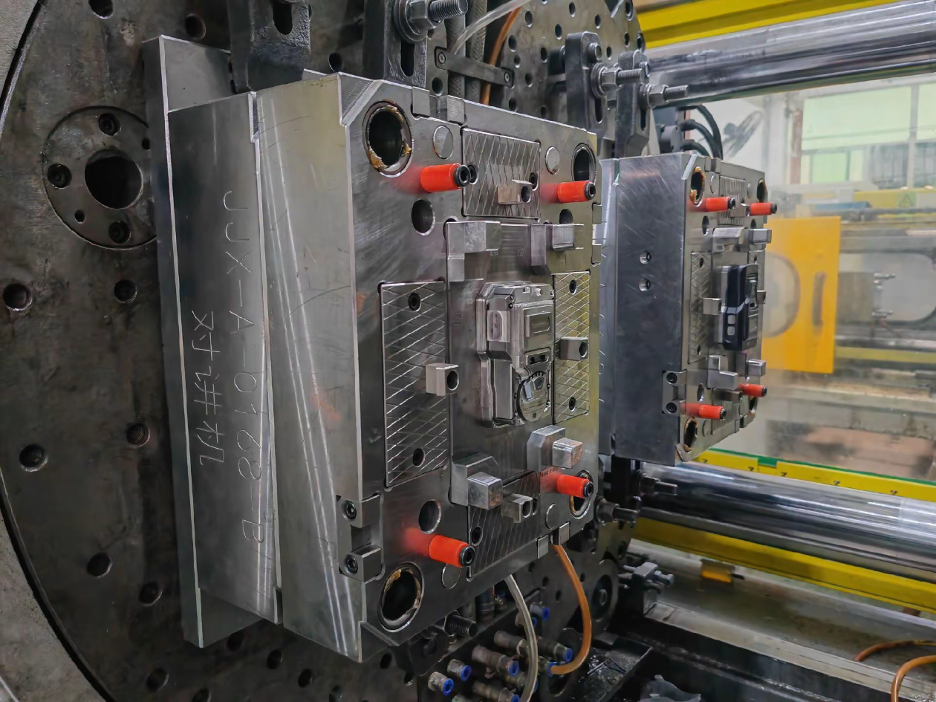

- The base material can be prepared with injection molding procedure which results in the primary shape of the component.

- The surface of the molded component is essential to provide stability to the second layer. Moreover, it includes cleaning, etching, or putting a primer.

- Then the second material is injected over the first which helps in making a link between both these two layers. This material has flexibility, durability, and resistance to environmental influences.

- After applying the second layer, cool the component and remove it from the mold. Trimming and finishing can be done to obtain a desired result.

What is over-molding

Applications

Below are the two common applications of this process:

Plastic Overmolding

Plastic molding process is the most common application of this process. In this process different plastics are blended to create a desired product with improved functionality. It is used for making grips for tools, medical equipment, or consumer electronics. Moreover, a hard plastic foundation can be overmolded with a softer rubber-like material. Therefore, this combination is useful for improving user comfort, but also provides additional protection and durability.

Metal Overmolding

Metal overmolding is less famous but becoming popular in industries that manufacture strong components. This method includes a metal substrate that is then overmolded with plastic. Furthermore, this combination is useful for products like connectors and automotive parts that require both strength and lightweight qualities.

Applications of Overmolding

Applications of Overmolding

Pros and Cons

There are various pros and cons of this process, few are mentioned below. It is recommended to understand it well before making a decision:

|

Pros |

Cons |

|

It combines different materials and provides better performance, such as grip and insulation. |

Development and tooling costs can be high, especially for specialized molds. |

|

It reduces assembling costs and does not require several components. |

Designing molds for overmolding can be more difficult than standard techniques. |

|

It creates complicated designs that cannot be created manually. |

It requires bonding of different materials so it may not bond well. So, without careful selection, bonding issues can occur. |

|

It has the ability to change color and texture of the product that increases product appeal. |

It requires more time to mold several layers of molding materials. |

|

Forms strong connections between materials, increasing the overall durability of the finished product. |

It is not suitable for all items, especially those which require single material for construction. |

Rapid Prototyping

Overmolding process heavily relies on quick prototyping. Manufacturers can assess the functionality and appearance of overmolded goods prior to full-scale manufacturing by allowing designers to quickly produce prototypes. By finding rapid prototyping services one can easily speed up the designing process and can detect issues early.

Rapid Prototype Casting

It is a complex method and useful for developing prototypes for complex designs. Moreover, this method is useful for producers to quickly produce molds from a variety of materials. Therefore, it allows them to efficiently test diverse designs and materials. Furthermore, it allows businesses to reduce consumption of time and expenses in contrast to traditional mold-making procedures.

Rapid Product Development

Companies can quickly adjust designs using overmolding to create working prototypes that closely match the finished product. This not only speeds up the development process, but also ensures that the products meet market demands successfully.

Considerations before Process

Below are some considerations that should be kept in mind before going for the process:

Environmental Considerations

Sustainability is the major concern in this hazardous environment so, it is better to choose a process which has different environmental benefits as mentioned below:

- There is no need of using separate components for streamlining the production so, it decreases the impact on the environment.

- Many products of the process can be recycled which allows it to manufacture compatible materials. These materials can easily be processed together at the end of their life cycle and support a sustainable economy.

- Many materials used in the process are created with environmentally friendly plastics. So, it uses biodegradable materials and those derived from renewable sources, which can help in reducing environmental pollution.

Material Considerations

It is recommended to choose your material wisely to enhance performance and durability. Below are some material considerations:

- A material should be compatible to enhance the stability of the product. The proper binding of substrate and overmolded material is crucial. This adhesion can be frequently improved by surface treatments or primers.

- It is better to understand the thermal properties of the object to avoid warping difficulties. It is crucial because different materials have different thermal expansion rates, which can impact product performance as temperatures fluctuate.

- The material must have the resistance properties to improve durability and functionality. So, the chosen product must have the ability to withstand certain chemicals or environmental conditions.

Conclusion

To summarize, the overmolding process is an amazing technique for improving product design and functioning through the use of various materials. One can use plastic or metal overmolding to produce products that can fulfill consumer needs. Moreover, the importance of rapid prototyping, which includes rapid prototype casting, is equally important during the process because it allows businesses to streamline their product development efforts and shorten time to market. Get your overmolding services to find out the solutions of all the issues.

FAQs

1. What materials are typically used in overmolding?

Overmolding frequently employs a range of plastics, including polypropylene, thermoplastic elastomers (TPE), and polyvinyl chloride. Metal overmolding frequently uses base materials such as aluminum or steel.

2. How does the overmolding process improve product performance?

It improves product performance by combining the qualities of various materials, resulting in components with superior grip, durability, insulation, and resistance to environmental influences. This adaptability enables the development of more practical and visually appealing goods.