Source:Pexels

Atomization, the process of transforming bulk liquids into fine droplets, plays a crucial role across numerous industries. From manufacturing metal powders to pharmaceutical applications, different atomization techniques offer various advantages. In recent years, ultrasonic atomization has emerged as a promising alternative to conventional methods. This article compares ultrasonic atomization technology to traditional atomization methods, highlighting key differences and application areas.

Introduction: The Evolution of Atomization Technology

Atomization is a fundamental industrial process involving the breakup of liquids into fine droplets. It is essential in fields such as metallurgy, pharmaceuticals, and chemical engineering. Traditional atomization methods—water atomization, gas atomization, and rotary atomization—have been well-established for decades. However, advancements in ultrasonic atomization technology offer significant benefits, including increased precision and energy efficiency. The objective of this article is to provide a clear comparative analysis of ultrasonic atomization versus conventional methods.

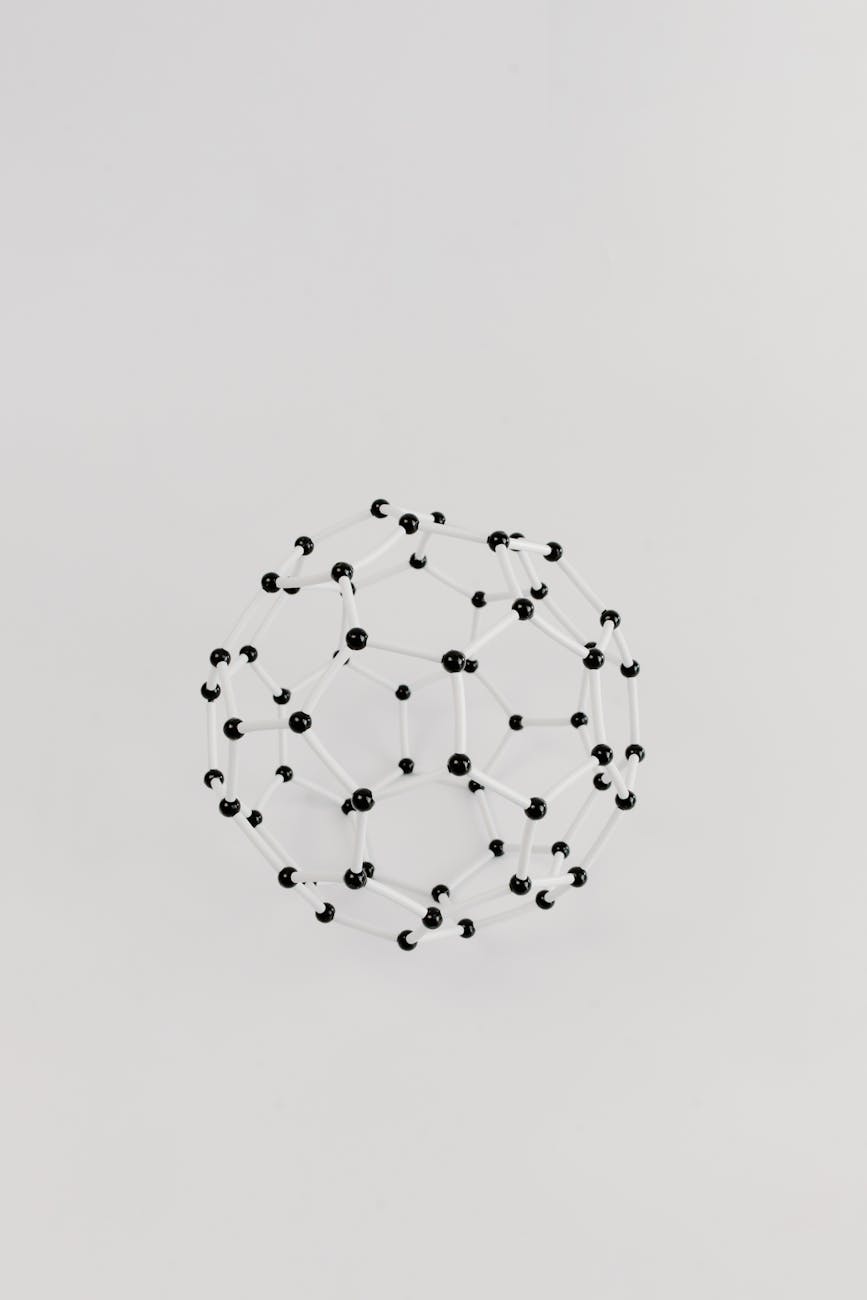

The Principle of Ultrasonic Atomization

Ultrasonic atomization utilizes piezoelectric transducers to generate high-frequency vibrations. These vibrations travel through a sonotrode (ultrasonic horn) to the liquid surface, creating capillary waves. The waves destabilize the liquid, resulting in the formation of microscopic, uniform droplets.

Key aspects of ultrasonic atomization include:

- High-frequency vibrations: Typically in the range of 20 kHz to several MHz, directly influencing droplet size.

- Uniform droplets: Achieved by precise frequency control, resulting in a narrow particle size distribution.

- Nozzle-less operation: Reduces clogging and maintenance issues, crucial for sensitive applications.

For an in-depth explanation of the principle, visit this detailed overview of ultrasonic atomization.

Overview of Conventional Atomization Methods

Traditional atomization methods remain widely used and have distinct operational characteristics:

Water atomization

This method involves disintegrating a stream of molten metal using high-pressure water jets. The rapid cooling effect of water leads to the formation of irregularly shaped particles with high cooling rates. It is widely used for ferrous alloys and economically favorable for producing powders in large volumes. However, it results in higher oxygen content and broader particle size distribution compared to inert gas-based methods, limiting its suitability for reactive or high-purity materials.

Gas Atomization

In gas atomization, molten metal is disintegrated by high-velocity inert gas jets—often using Laval-type nozzles to achieve supersonic flow. These nozzles ensure efficient atomization and promote spherical particle formation. The process takes place in a controlled atmosphere, minimizing oxidation and enabling production of high-quality powders, especially for reactive alloys. While it allows good control over particle size and shape, it involves high inert gas consumption and complex equipment.

Rotary (Centrifugal) Atomization

Utilizes centrifugal force by rapidly spinning discs or cups to disperse liquid into droplets. While highly productive, it often suffers from broader particle size distribution and mechanical complexity.

Each atomization method presents distinct limitations that impact process efficiency and product quality. Energy consumption can vary significantly - gas atomization, for instance, requires large volumes of compressed inert gases, often cooled or preheated, which increases operational costs. Droplet or particle uniformity also differs: rotary atomization typically yield broader size distributions, requiring post-processing such as sieving. Additionally, material waste is a concern, particularly in high-velocity spray systems, where overspray and uncontrolled dispersion can lead to lower material yield. These factors must be carefully considered when selecting an atomization technique for a specific application.

Key Differences: Parameters and Performance

Droplet Size and Uniformity

Ultrasonic atomization generates consistently uniform droplets, typically ranging from sub-micron to tens of microns, depending on frequency control. In contrast, conventional methods yield broader particle size distributions, often requiring additional sie

Energy and Material Consumption

Energy efficiency is a key advantage of ultrasonic metal atomization, as energy is used primarily to melt the material—not to drive high-pressure gases or rotating components.

Speed and Flow Rate

Conventional methods, such as pressure and gas atomization, are generally better suited to higher-volume production with high flow rates. In contrast, ultrasonic atomization excels in precise, low-flow-rate applications where accuracy is crucial.

Conclusion: The Future of Atomization

Ultrasonic atomization presents distinct advantages—precision, energy efficiency, and high-quality output—making it particularly suitable for specialized and advanced applications. While conventional methods still dominate in large-scale industrial scenarios, the choice between methods depends largely on specific requirements, including scale, precision, material sensitivity, and energy considerations. Given current trends, ultrasonic atomization technology will likely expand further, becoming increasingly relevant in high-tech and precision-driven industries.