Custom sheet metal parts play a critical role in industries ranging from automotive to aerospace, construction, and electronics. Whether it’s a component in an aircraft or a structural element in a building, precision is key to ensuring that these parts perform optimally. Precision in manufacturing custom sheet metal parts not only guarantees quality but also contributes to the overall efficiency, durability, and safety of the final product.

In this article, we will explore why precision is essential in the manufacturing of custom sheet metal parts and how manufacturers can achieve it.

1. Ensuring Structural Integrity

The primary reason precision is crucial in custom sheet metal manufacturing is to ensure the structural integrity of the parts. Sheet metal components are often subjected to high stress, whether they are used in the construction of bridges, vehicles, or machinery. If these parts are not manufactured to exact specifications, they may fail to handle the stress, leading to catastrophic failures.

Accurate dimensions, cuts, and bends in sheet metal parts are essential to distribute loads evenly and maintain the integrity of the product. Even minor deviations from the specified measurements can lead to weaknesses in the structure, compromising its ability to function under expected loads.

Example:

In industries like aerospace, precision is non-negotiable. A slight miscalculation in the manufacturing of sheet metal components for aircraft can lead to severe safety risks. Ensuring that every part is crafted with accuracy enhances the safety and longevity of the final product.

2. Improving Product Efficiency and Performance

Precision is also a critical factor in determining the performance and efficiency of products made from custom sheet metal parts. Whether it’s an automotive component or an HVAC system part, the performance of the entire system relies on each component fitting perfectly within the overall assembly.

For instance, in mechanical applications, the alignment of parts needs to be exact to ensure smooth operation. If a custom metal part is even slightly off, it can cause friction, vibrations, or mechanical failures, all of which reduce the efficiency of the machine. Precision helps ensure that all parts work in harmony, reducing energy loss and enhancing overall performance.

Example:

In the automotive industry, custom sheet metal parts are used for engine components, exhaust systems, and chassis parts. Each piece must meet tight tolerances to ensure the vehicle operates efficiently and without issues such as engine knocking, excess vibration, or poor fuel efficiency.

3. Cost Efficiency and Waste Reduction

Another significant benefit of precision in manufacturing custom sheet metal parts is cost efficiency. When parts are manufactured with precision, there is less material waste, which reduces costs. Inaccurate cuts or misaligned holes can lead to scrap, increasing both material costs and production time.

Precision reduces the need for rework or replacement, ensuring that manufacturers can meet deadlines and avoid costly errors. Advanced technologies such as CNC (Computer Numerical Control) machines are widely used to enhance precision and minimize waste in the manufacturing process.

Example:

Using CNC machines in the fabrication of custom sheet metal parts allows manufacturers to achieve high levels of accuracy, which in turn reduces material waste. This efficiency not only saves money but also supports environmental sustainability by minimizing the amount of discarded materials.

4. Enhanced Durability and Longevity of Parts

Precision in manufacturing custom sheet metal parts directly contributes to the durability and longevity of the final product. Inaccuracies in dimensions or design can lead to stress points where the material is weaker, which in turn reduces the lifespan of the part. When parts are manufactured with exact precision, they can better withstand wear and tear, resist corrosion, and endure harsh environments.

This is particularly important for industries like construction, where custom sheet metal parts are exposed to extreme conditions. Accurate dimensions and robust construction ensure that these parts do not suffer from early degradation, saving businesses from frequent repairs or replacements.

Example:

In the construction industry, custom sheet metal parts are often used for building facades, roofing, and structural components. If these parts are manufactured with precision, they are more likely to withstand the elements such as wind, rain, and temperature fluctuations, thereby extending their useful life.

5. Adhering to Industry Standards and Compliance

Manufacturers of custom sheet metal parts must adhere to strict industry standards and compliance regulations. Precision is necessary to meet these standards, which often dictate exact measurements, tolerances, and material properties. Failure to meet these standards can result in costly fines, product recalls, or even legal action, especially in industries like healthcare, defense, and aerospace.

In some cases, precision is necessary to ensure that the sheet metal parts are compatible with other components in a larger system. For example, in electronic enclosures, precise manufacturing ensures that the metal casing fits perfectly with circuit boards and other internal components, maintaining the functionality and safety of the device.

Example:

In the medical industry, custom sheet metal parts are used for equipment such as MRI machines, surgical instruments, and hospital furniture. Precision in manufacturing is necessary to meet strict hygiene standards and ensure the safety of both patients and healthcare workers.

6. Improving Aesthetic and Functional Design

Precision manufacturing of custom sheet metal parts also plays a role in improving the aesthetic and functional design of products. In industries like consumer electronics or home appliances, the appearance of the final product is almost as important as its functionality. Precise cuts, smooth edges, and flawless finishes are essential to creating a product that looks professional and appeals to consumers.

Precision also enhances the functionality of the product by ensuring that it operates as intended. For example, in custom enclosures for electronic devices, precision in cutting and forming the sheet metal ensures that components fit perfectly, with no gaps or misalignments that could affect performance.

Example:

In the consumer electronics industry, custom sheet metal parts are often used for the casings of laptops, smartphones, and other devices. Precision manufacturing ensures that these parts are sleek and smooth, providing an aesthetically pleasing and functional design.

7. Enabling Complex Geometries and Designs

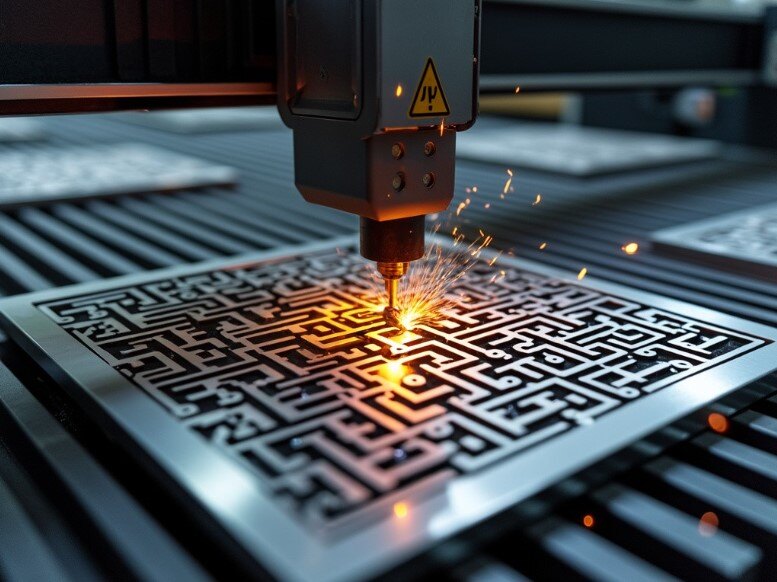

Advancements in technology, such as laser cutting and CNC machining, have made it possible to achieve precision in even the most complex geometries. Custom sheet metal parts with intricate designs, tight tolerances, and unique shapes can now be manufactured with remarkable accuracy.

Precision is essential when working with complex designs, as even the smallest deviation can lead to a failure in the final product. Whether it’s a custom bracket for a mechanical system or a highly detailed metal casing, manufacturers can now produce parts that meet exact specifications without sacrificing quality or design complexity.

Example:

In the electronics industry, custom sheet metal parts are often designed with complex geometries to accommodate small and sensitive components. Precision manufacturing ensures that these parts fit together seamlessly, allowing for the development of more advanced and compact devices.

Conclusion

The importance of precision in manufacturing custom sheet metal parts cannot be overstated. Precision ensures that parts are durable, efficient, and cost-effective, while also enhancing safety and meeting industry standards. From improving the performance of mechanical systems to reducing waste and enabling innovative designs, precision is at the core of successful custom sheet metal manufacturing. By prioritizing accuracy and using advanced technologies like CNC machining, manufacturers can consistently produce high-quality custom sheet metal parts that meet the demands of modern industries.