Can a hi-fi company really produce sustainable products? It’s a question that comes up time and time again, and to answer it there are seemingly endless factors to consider.

But, you might be asking why sustainability actually matters in hi-fi. Well, when a product with electric elements is disposed of without being properly recycled, it more often than not ends up in landfill. That means that over time toxic chemicals, including lead and mercury, leak into the ground.

This causes health issues for those living in the nearby communities and wildlife, affecting their water and land quality dramatically.

To put all that in perspective, the World Health Organisation says that in 2022, an estimated 62 million tonnes of electrical waste (or e-waste) was produced globally with only 22 per cent of it being properly recycled.

All is not lost, however, as we are seeing changes in the way some hi-fi and home cinema products are created – and one company aiming to make a difference is Fell Audio.

Fell is the brainchild of Luke and Matthew Tyson (respectively grandson and son of hi-fi retail giant Peter Tyson).

It’s a company that is still in its infancy, with its doors only opening last November. Based in Carlisle in Cumbria, the hi-fi brand offers amps and CD players at an entry-level price with sustainability at the forefront. There's a streamer in the works as well.

We caught up with Luke Tyson to learn more about Fell Audio’s journey.

Supporting British

For Tyson, using components and materials entirely sourced from British suppliers was incredibly important and sustainability was one of his “non-negotiables.”.

Reducing the air miles of various components for products means there are significantly less carbon emissions created as a result of the process.

“At a certain price point,” he says, “nothing is getting built in the UK.” He clarifies that companies that do make products at Fell’s price point (the CD player will set you back £499) are often using components that are made overseas.

“We realised there wasn't really anyone building something in the hi-fi industry in the UK sustainably at a price a more normal enthusiast can afford,” Tyson adds.

He acknowledges that this wasn’t without its challenges, of course. Instead of sourcing only four or five companies to supply a range of components overseas, for example, Fell Audio uses closer to 40 manufacturers and distributors.

It also meant the company had to get creative about who they were using to build the products. In the amp, for example, Fell Audio uses recycled plastic from a firm that typically produces shower heads in order to keep costs down but still buy British.

Taking this approach appears to be a win-win for Tyson, though: Fell can support British businesses while also massively reducing the company’s air miles.

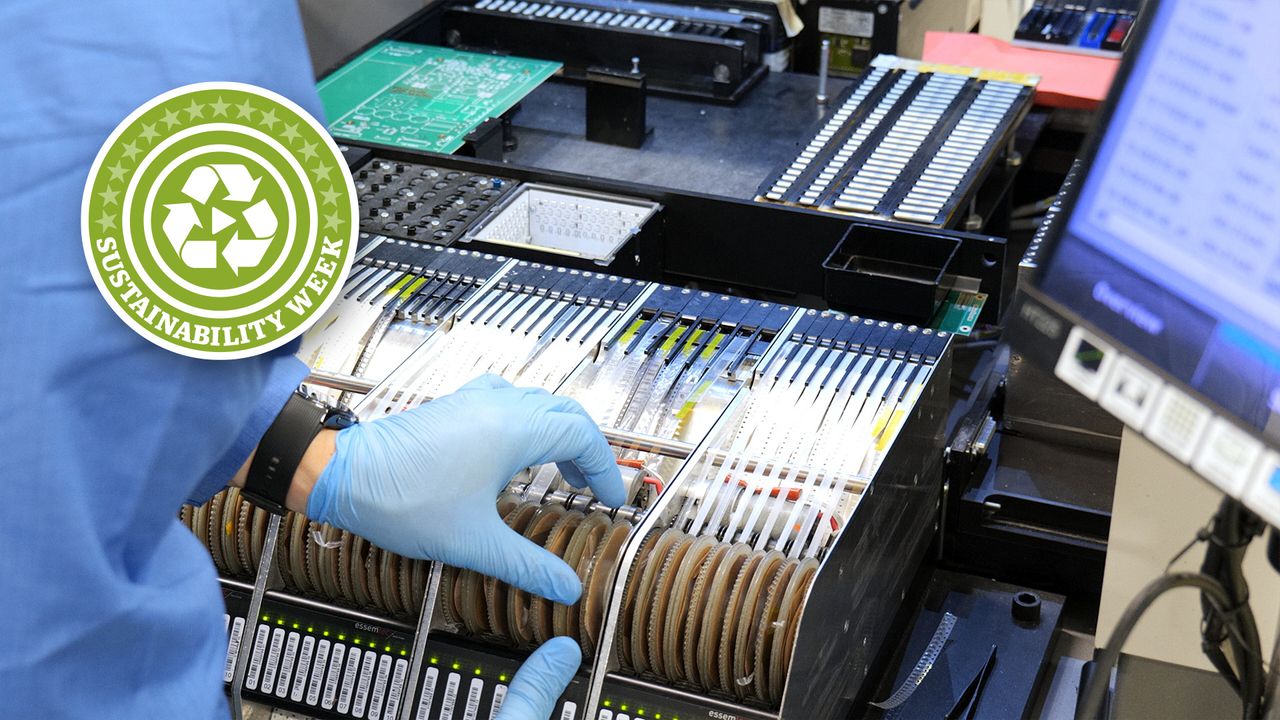

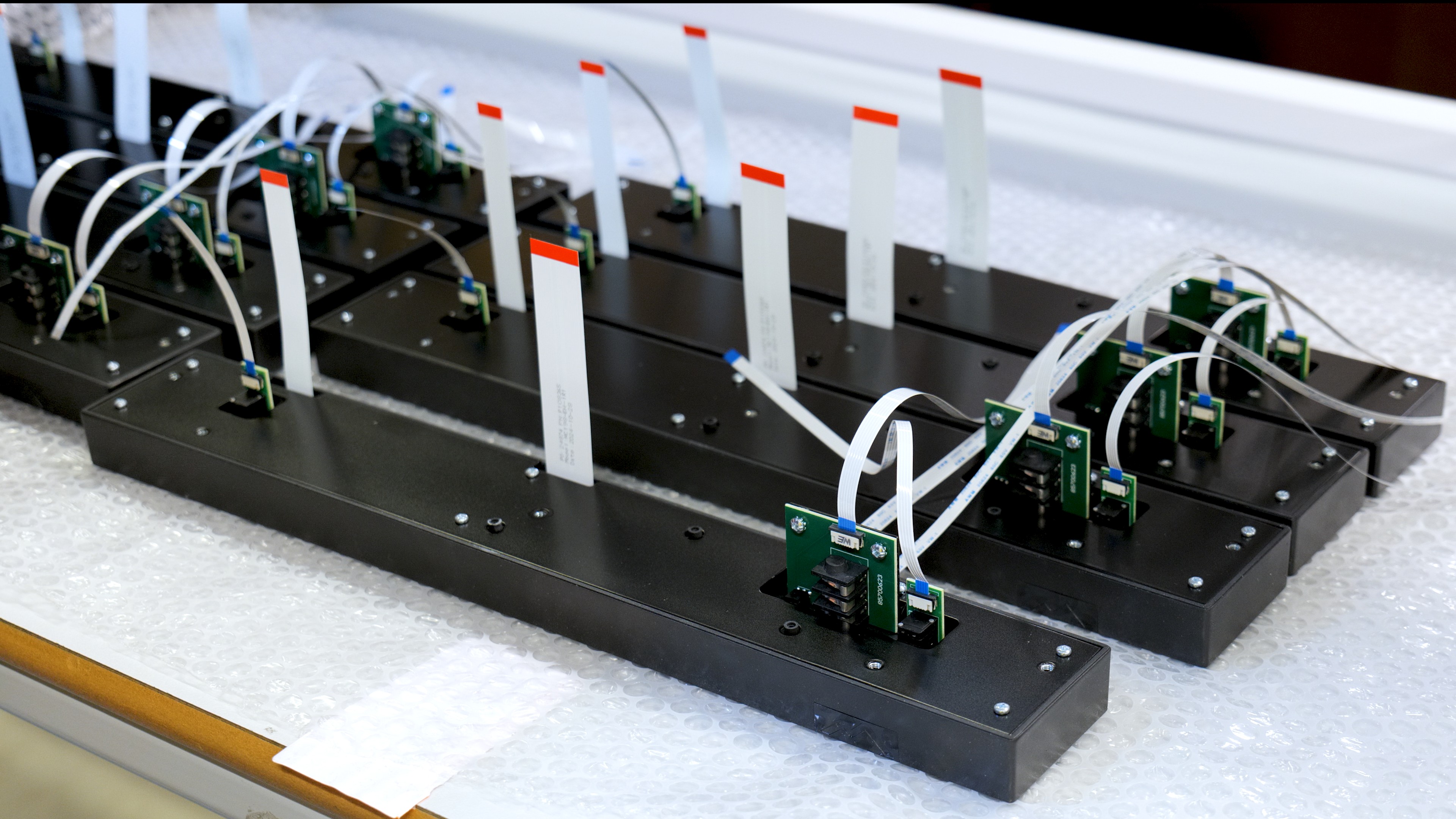

Because of this, Fell Audio is able to produce all of its PCB boards in the UK. Even the volume knobs and feet are built in-house, which Tyson says is practically unheard of at this price range.

Repairable design

Not being able to repair your own hi-fi products is one of the main reasons customers often find themselves having to dispose of them, but Tyson says Fell Audio provides a five-year warranty with a repairable design.

He says the company has "a big control over the product’s life span”, citing the fact that the majority of the components are easily attainable, and so a product can be fixed by Fell Audio in the same building it was manufactured in.

This is more common with premium British-based brands such as Naim and Rega, but Tyson adds this is usually at a much higher price point.

Fell has only been producing its products for about 12 months, so the company has yet to put this into practice, however.

Down to the ink

On top of that, all of the packaging components are recycled, including the foam, and the cotton tote bag that comes with the product.

Even the ink in the cardboard is fully recyclable. In most cardboard boxes with writing, the chemicals in the ink dye mean there are still pollutants seeping into the earth when it decomposes. So Fell uses non-toxic ink to sidestep that issue.

“I think if we had tried to do completely recycled packaging ten years ago, it would have been very tricky,” Tyson comments. But he says that more and more companies are doing it now, such as supermarkets using recycled paper bags rather than one-use plastic bags.

A representative from Fell says that while the company has not released any carbon neutrality pledges, this is due to the company still being in its infancy.

“The hi-fi industry is a bit slower in following suit,” he notes. However, he thinks Fell’s sustainability ethos will “appeal to a new audience of hi-fi buyers”.

Tyson adds: “If customers want to buy a product that’s been made in this country in a responsible and sustainable way, I think we’re one of the few that can offer that.”

MORE:

These are the best 4K Blu-ray players right now

Check out the best stereo amplifiers on offer

And here are the best TVs under £1000