Australian mining firms should reject using gas and carbon capture technology to produce iron and steel, a report has found, even though renewable energy sources are taking longer than expected to manufacture.

Researchers from the Institute for Energy Economics and Financial Analysis (IEEFA) released the findings from a study of the global green iron and steel market, which is ramping up as more nations seek to reduce their emissions.

The advice also comes after a report from The Superpower Institute found Australia could more than triple its export revenue by 2060 if it moved swiftly to produce iron using green hydrogen.

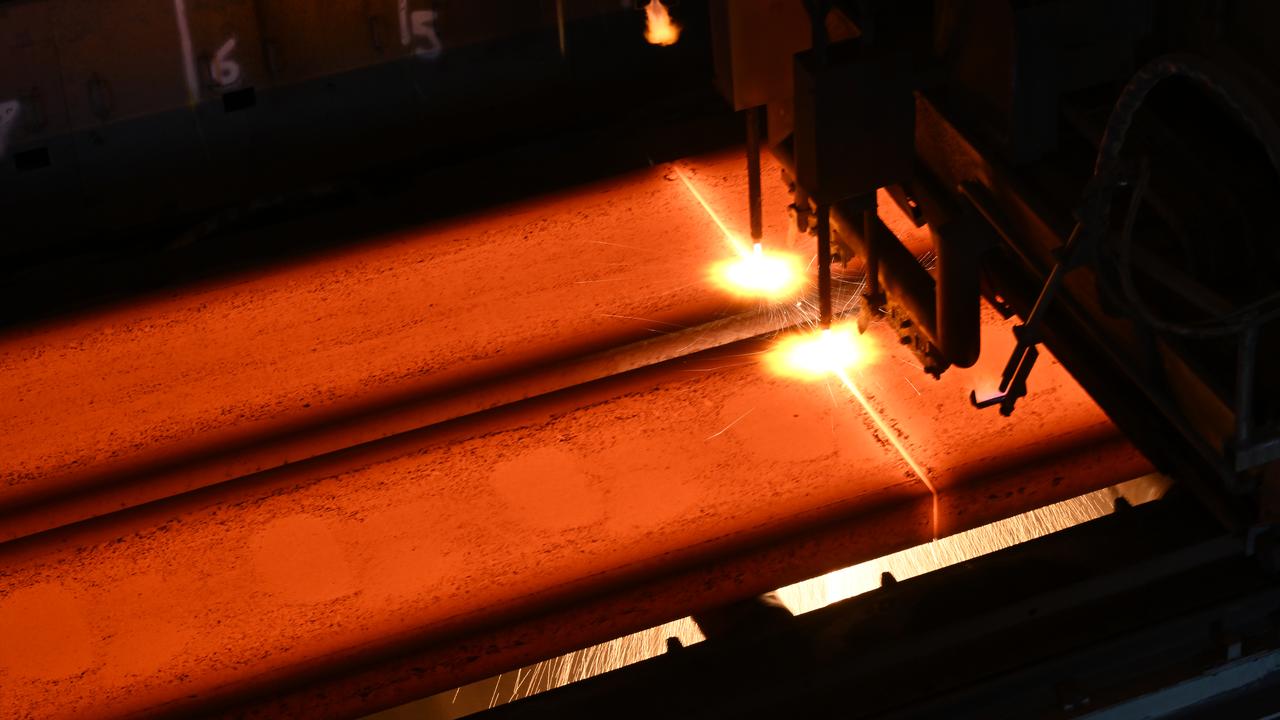

Green iron, which is made using renewable energy resources, has the potential to cut 90 per cent of emissions from the steelmaking process.

The institute's study into direct reduced iron technology, prepared by analysts Soroush Basirat and Simon Nicholas, looked at efforts to produce green iron in different parts of the globe.

It found the world's first commercial-scale green iron facility would start producing the metal in late 2026 in Sweden using an electric arc furnace powered by hydrogen.

Australia's mining firms should pay close attention to how the company behind the project, Stegra, achieved the feat, Mr Nicholas said, and how it was able to sign long-term, off-take agreements with companies willing to pay more for a greener product.

An alternative approach to removing emissions from iron production used gas with carbon capture storage, he said, but major firms were already questioning its viability.

"We're at a bit of a crossroads here in Australia with green iron," he told AAP.

"There's a risk we will go down the gas and carbon capture and storage route, which will lock in gas and lock out green hydrogen for a long, long time."

US iron-making firm Midrex called carbon capture technology a "niche technology" that would be "too expensive" to use at scale, the report found.

Iron producers in other nations, such as Oman, planned to cut emissions from steel by using a mix of green hydrogen and gas, Mr Nicholas said, which could be an option for Australia.

"We should be able to ramp up green hydrogen over time and that (approach) would put Australia's green iron opportunity on the right decarbonisation pathway," he said.

"It would be a signal of intent."

Green hydrogen has proven difficult to produce in Australia to date, with two firms backing out of projects in Queensland and Western Australia in recent months.

But a report from The Superpower Institute found using the zero-emission fuel to produce green iron could boost Australia's export revenue to $386 billion a year by 2060.

The nation's first green iron plant, Fortescue's Christmas Creek project, is expected to begin production late in 2025.