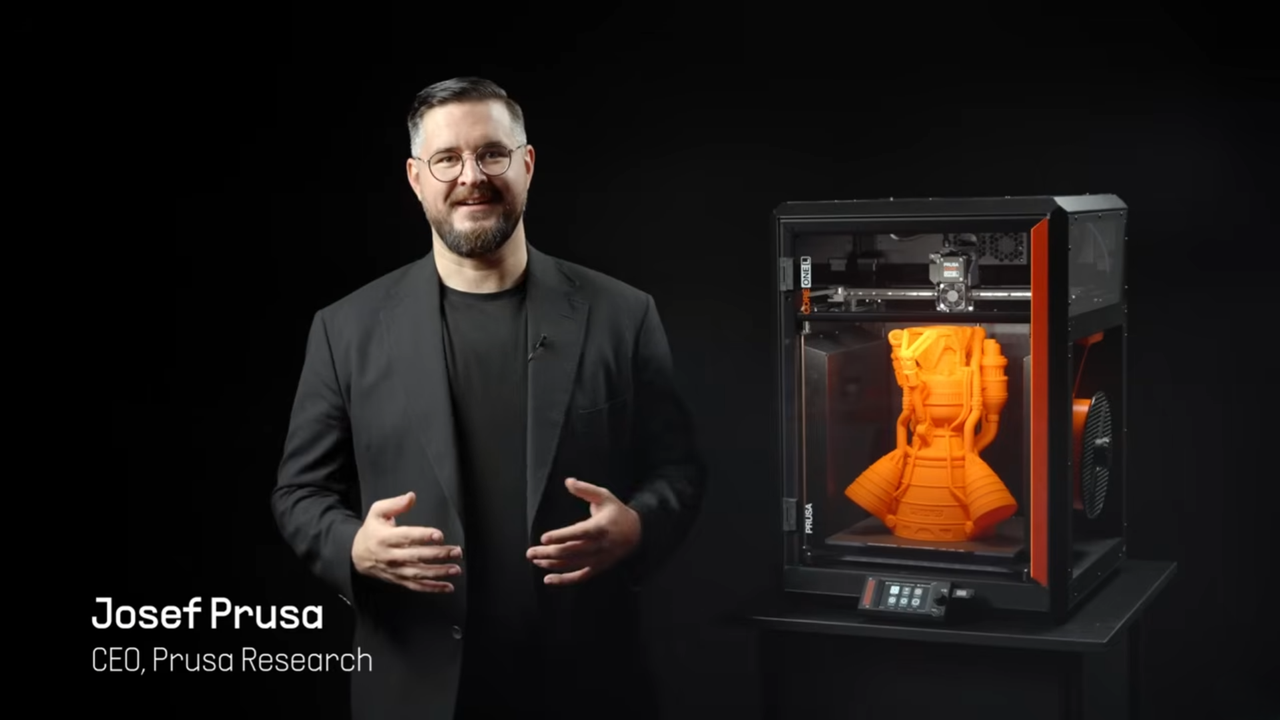

Josef Prusa, who was recently awarded the Czech Medal of Merit for contributions to the nation’s economy, announced his company’s newest 3D printer, the CORE One L, at an exclusive media event in Prague. The new Core XY printer is a departure from his original i3 model and boasts a 300 x 300 x 330 mm³ build volume. Prusa said he wanted a larger format printer that could still fit on your desk and be fairly easy to move. The new design is only 10% larger on the outside and uses aluminum parts to keep the weight similar to the first CORE One.

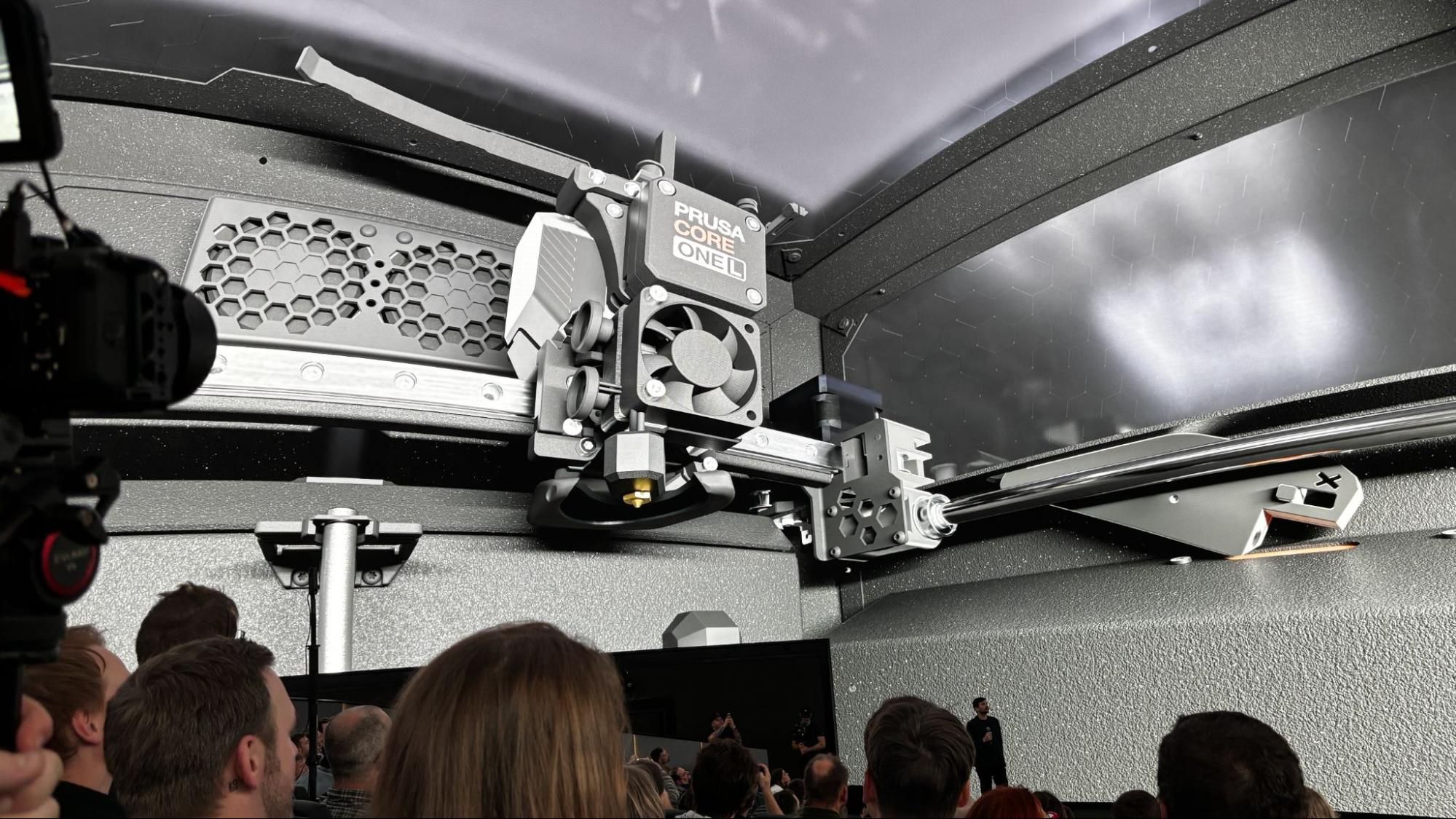

Prusa invited reporters and content creators from around the globe to take a look inside his new machine, literally. The event was held at the Prague Planetarium, located down the street from his company headquarters. Prusa’s team put together an eye-popping 3D presentation to make use of a 360° digital screen (normally used for star gazing shows), which placed the audience “inside” the CORE One L as it was printing.

Prusa hammered home his company’s dedication to security, noting that the CORE One L, like all his machines, never needs to connect to the internet to operate and features a removable Wi-Fi module. All the electronics are built in-house by Prusa Research on its own PCB line in Prague, with most of the printer’s components produced within the European Union. Final assembly takes place either in Prague, Czechia, or at the Printed Solid factory in Delaware, USA.

The CORE One L has several interesting new features, including an AC-powered heated bed made from a solid block of cast aluminum with embedded industrial magnets to hold the build plate firmly in place. Fans mounted beneath the bed provide rapid convection heating, capable of raising the chamber temperature to 60 °C for printing engineering-grade materials. A clever G-code routine lets the printer open and close its vents automatically using a prong on the toolhead, while a handy internal switch makes feeding TPU effortless.

Prusa explained the CORE One L will come mostly assembled and factory-calibrated, making the machine practically plug-and-play. The retail price for the CORE One L is $1799 USD, including all import duties and tariffs.

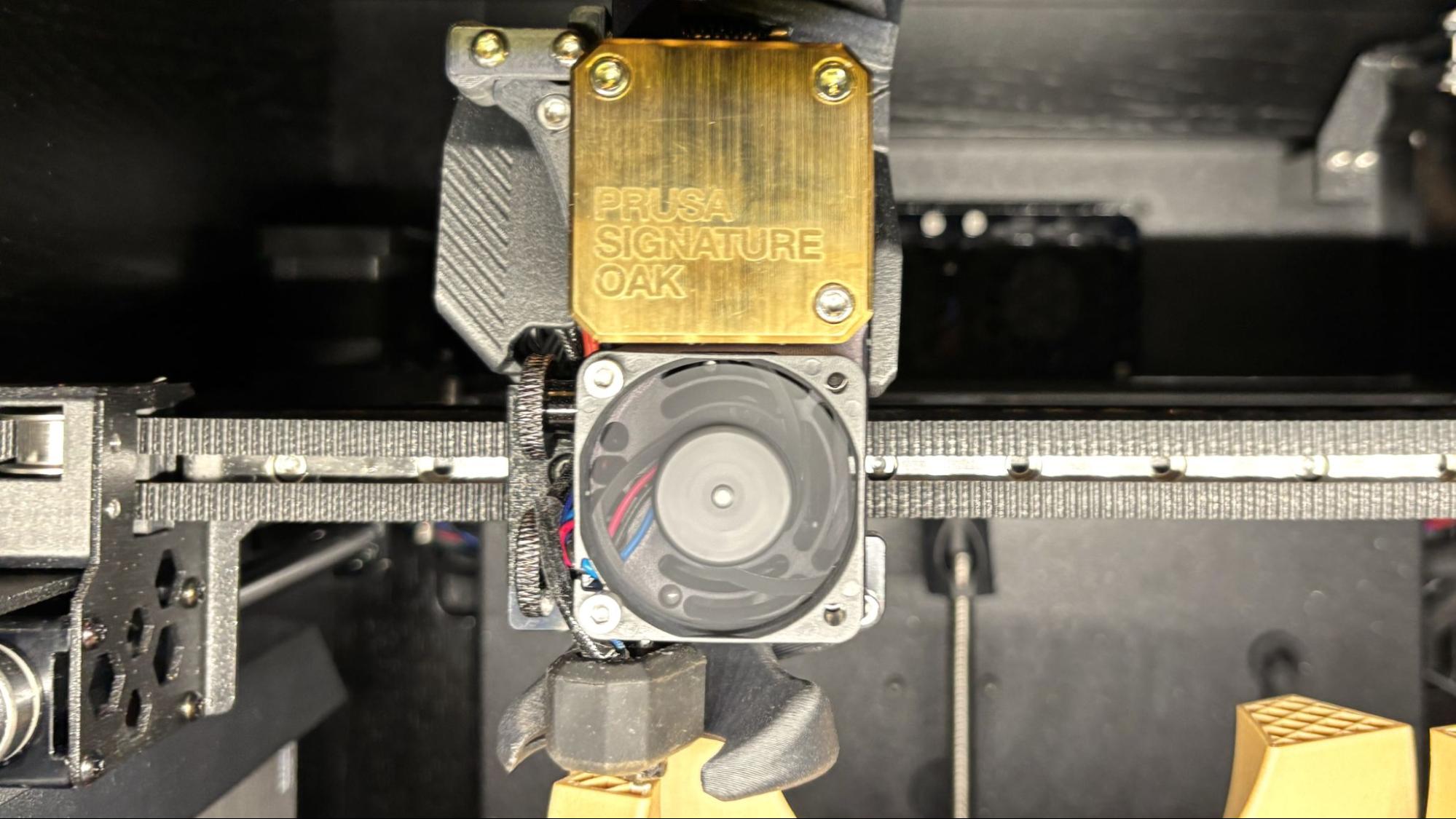

Josef Prusa also presented a limited edition “Signature Oak” CORE One, a tribute to his late father, who was a skilled woodworker. The machine is nestled in a wooden case, handmade by local Czech craftsmen from 100-year-old oak.

The CORE One’s indented sides are replaced with flat magnetically latched panels that hide the spool holder and tool storage inside the printer’s enclosure. This is not the cheap plywood printers of RepRap’s early days, but a beautiful handcrafted machine perfectly suited for display in the home. Only 250 Signature Oaks will be made, so hurry up if you want to snag one for yourself. Prices were not released for the machine.

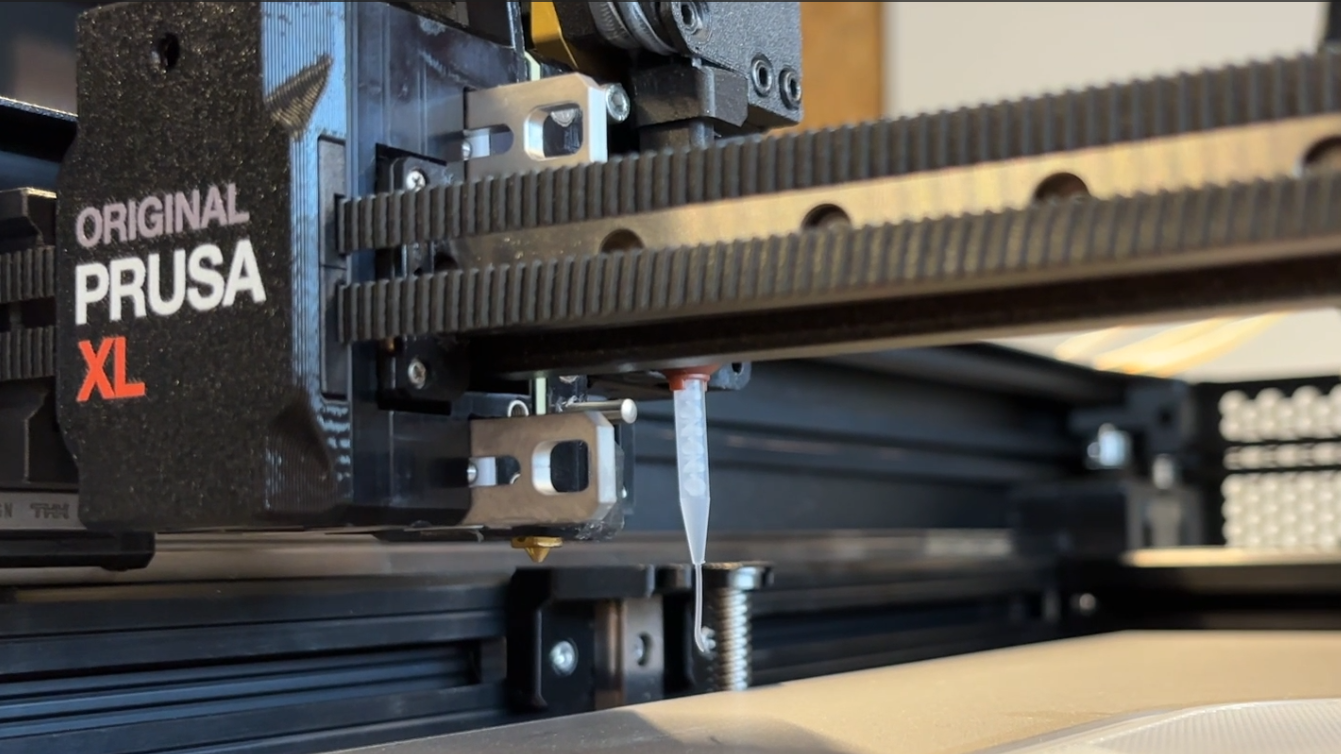

The Prusa XL stole the show with the announcement of a new tool head system coming in 2026 that will be able to print silicone, epoxy, and liquids. A demo unit was on display with a prototype tool head that had printed extremely soft silicone gel. The material comes in two parts, stored in tubes wrapped around typical FDM spools. A mysterious box mounted on the side of the machine strips the tubes and mixes the two parts, which is then pushed through the Bowden tube for the remaining distance to the nozzle. The material takes about eight minutes to dry before it can be peeled from the bed. Prusa said the new technology is a massive breakthrough that will allow people to not only FDM print silicone but also apply it directly to parts printed with normal materials from the other tool heads.

He said the new method has the potential to enable the XL to print other soft materials, from glue to chocolate. The modification will need to be somewhat permanent to the machine, and though the price was not disclosed, it was hinted at being vastly more affordable than current industrial options.

3D printers were not the only thing being presented. Josef Prusa announced that his company would lead the way with an open source, universal spool-tagging system called OpenPrintTag. The tags are being included in fresh spools of Prusament as we speak, with the CORE One L being the first 3D printer fully compatible with the system.

Companies like Bambu Lab, Creality, Snapmaker, and Anycubic all include proprietary RFID tags in their house-brand filaments. These tags inform the printer which material is being loaded and hold information such as material type, color, and, in advanced systems, even weight and proper print settings. Unfortunately, each company uses an exclusive tagging system that can only be read by their own machines. It's offered not only as a convenience but as a subtle way to encourage customers to stay within the brand’s ecosystem.

The system developed by Prusa Research seeks to change that by immediately partnering with other filament companies. 3D Fuel, Numakers, Filament PM, Fillamentum, Polar Filament, and of course Printed Solid are already on board. The tags are embedded on donut-shaped stickers, which can be purchased separately, programmed with a free app, and added to any user’s collection of spools. The tags are reprogrammable and could be easily combined with refillable spools for a more economical solution to spool management.

Prusa Research is not seeking to profit from the system, and blank tags will be made available soon. Pricing should start at $5.99 US for a 10-pack. Readers will be made available to connect Prusa machines, and any printer that can talk to Prusa Slicer, to the new Open Print Tag system.

Prusa hopes that other manufacturers consider adopting a compatible system to throw open the gates to closed filament gardens.

The company also kicked off its Black Friday sales event today, which you can read about here.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.