A crack found in December last year in the undercarriage frame of a Shinkansen train car may have widened from the previous day, the government's safety board said Thursday in its interim report on the incident, citing data recorded by the train.

According to the report, the Japan Transport Safety Board inferred that the crack's occurrence and expansion were attributable to inappropriate work by Kawasaki Heavy Industries, Ltd. -- the manufacturer of the frame -- on the steel the frame was made of, including excessively scraping the part.

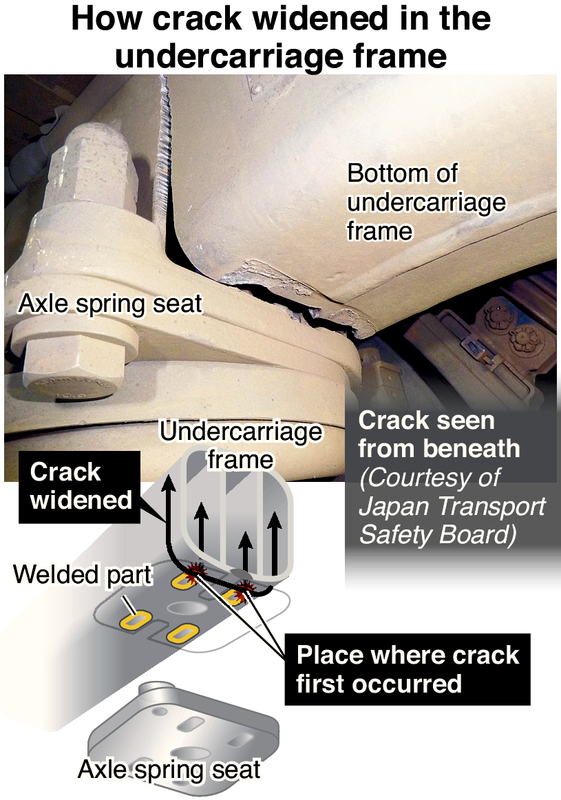

The crack occurred in two places near the bottom of the frame, around where an axle spring seat was welded to the frame, and widened apparently due to metal fatigue, according to the report.

At a Kawasaki Heavy manufacturing site, workers substantially scraped the frame's steel, to prevent the bottom from rattling, when they attached an axle spring seat to the frame.

This practice contravened the maker's in-house work instructions.

The design criteria required the steel component to be at least 7 millimeters thick, but the thinnest part of the component was scraped down to 4.7 millimeters.

An experiment conducted by the board showed that if the steel component was thick enough, as initially designed, it would take about 35 years for a crack to reach the edge of the bottom of the frame.

However, if it was made thinner, it would take only about five years. This led the board to say in its report that the excessive scraping of the part resulted in its insufficient strength.

The train's recording device preserved data on the pressure applied on air springs, which supported the car in four spots. The board's analysis revealed that the load on areas near the crack began dropping on the afternoon of the day before the crack was detected, leading to an imbalance in the car body.

With the view that the crack had already widened enough to affect the strength of the undercarriage frame, the board said such abnormalities can be detected at an early stage if the data is constantly monitored.

In light of this, the board requested Land, Infrastructure, Transport and Tourism Minister Keiichi Ishii to thoroughly conduct manufacturing management and make effective use of findings such as data on the pressure applied on air springs.

The incident occurred on Dec. 11 in West Japan Railway Co.'s N700 series Nozomi No. 34 bound for Tokyo from Hakata. As the crack was on the verge of a rupture, the board designated the case as the Shinkansen's first-ever "serious incident."

JR West continued operating the Shinkansen for about three hours after becoming aware of abnormal sounds and smells, among other things.

The board said it will investigate various issues, including this conduct by JR West, to compile its final report.

Read more from The Japan News at https://japannews.yomiuri.co.jp/