There’s a growing trend among European automakers to reduce waste and protect our fragile environment. Jaguar Land Rover recently announced plans to remove magnesium from the dashboard's cross-car beam, a move expected to cut more than 50,000 tons of CO₂ annually. BMW, meanwhile, claims that roughly a third of the new iX3 electric crossover’s weight comes from recycled materials.

Mercedes has an eco-agenda of its own, and it involves going back to basics by using good ol’ screws. As part of its “Mission X” initiative promoting circularity, the company says it will make modern headlights repairable for the first time. While today’s headlights rely on glue to hold the lens, cover trim, frame, housing, and electronics in place, the headlights of tomorrow will be screwed together.

This approach makes it easier to replace a faulty individual component instead of having to swap out the entire headlight. Not only does it reduce waste, but it also lowers repair costs and extends the headlight’s lifespan. Take, for example, a stone chip damaging the lens: rather than replacing the whole unit, a technician could simply unscrew the lens and install a new one.

If you’ve had to replace a faulty headlight out of pocket recently, you know how shockingly expensive adaptive LED units can be. Avoiding a full assembly replacement reduces harmful emissions and makes the headlight easier to recycle, since individual parts are simpler to separate and sort.

Mission X goes far beyond making headlights repairable. Mercedes has figured out how to reuse fiberglass-reinforced polyamide from recycled airbags to produce engine mounts and valve housings. Elsewhere, plastics from scrapped vehicles could be repurposed for the underbody cladding of new models.

The next emissions-cutting initiative may not sit well with customers and their expectations when buying a brand-new Mercedes. Research shows that recycled plastic derived from old tires could serve as the basis for artificial leather. The German luxury brand says that combining repurposed plastic with bio-based proteins results in an “innovative material that resembles real leather in composition and structure.” It reportedly offers double the maximum tensile strength and is far more durable in extreme temperatures.

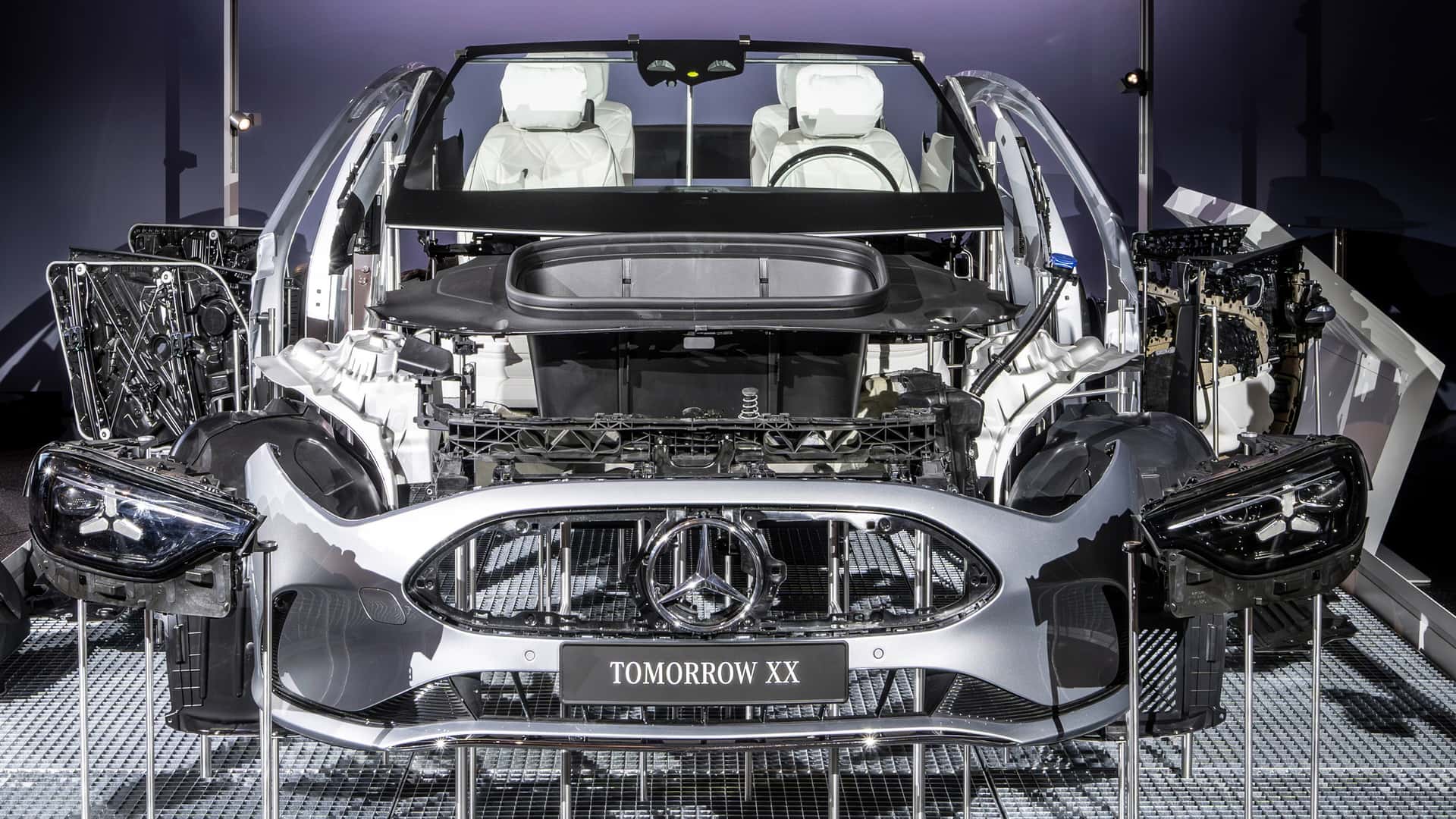

Mercedes Tomorrow XX

Mercedes has also identified a way to use fibers from discarded tires for vibration dampers. In addition, recycled PET reduces the weight of a door pocket by 40 percent compared to today’s standard practice of primarily using plastic. The company is also exploring recycled brake pads made with approximately 40 percent waste sourced from old brake pads.

All of these methods contribute to significantly lower emissions by relying more on secondary raw materials. People tend to focus only on emissions coming from the exhaust tip, but a car impacts the environment well before the driver puts the first mile on it. Mercedes aims to reduce pollution by making greater use of what’s already available and limiting its reliance on primary materials. More serviceable headlights are just one way car production can become more environmentally friendly.

Source: Mercedes-Benz