Christmas can be a busy time, you have gifts to buy, wrap, and deliver to your loved ones. It is a familiar feeling for staff at Amazon's huge fulfilment centre who are preparing for their busiest time of the year.

Opened in September, it has delivered tens of thousands of parcels a day. But with Black Friday and Christmas just around the corner, the demand is expected to double, with staff offered overtime to ensure everything runs smoothly.

The ECHO visited the Knowsley site to see what staff are doing ahead of Christmas. Spread out over five floors, the 636,000 sq. ft. fulfilment centre is the same size of ten football pitches.

Reporter Charlotte Hadfield visited the site. This is what she found.

After entering the warehouse, we're greeted by a huge storage area that's filling up with everything from children's toys to coffee machines and cat food. The online retailer has 30 "fulfilment centres" across the UK, where staff pick, pack and ship orders from.

The first product to be shipped from the Knowsley site was an air fryer, which is one of its most popular products, along with ironing boards. Anyone who has ever ordered from Amazon will know speed is everything, with parcels often arriving at your door less than 24 hours after you bought them.

Staff work around the clock to help fulfil these orders - with a typical full-time shift pattern involving four 10 hour shifts followed by three days off. The new site has created 700 new jobs in everything from IT to safety, and those responsible for picking, packing and shipping orders.

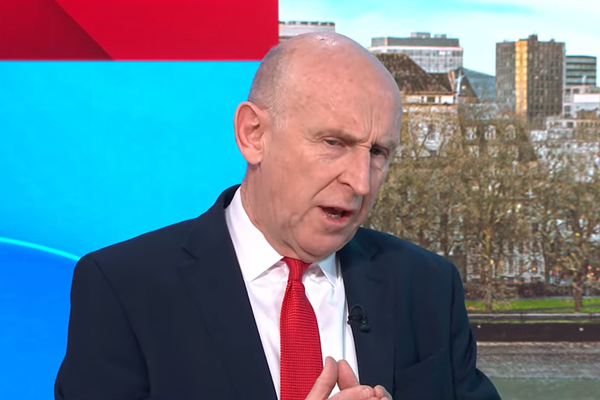

Amazon's General Manager for Knowlsey, Tony Carr, said technology also plays an important part in keeping up with customer demand by taking parts the manual handling process away. Tony told the ECHO: "This is the big lever we have as a new warehouse - we've got some really nice technology.

"We're still new, we're still optimising how we use that technology, and the ideas for how we can do better are coming from the people who are working with it everyday."

Unlike some of Amazon's other fulfilment centres, the particular one in Knowsley doesn't use robot pickers. But it does rely on a range of other technology, from finger scanners to a parcel identifier and paper and taping machines.

What happens when your parcel arrives at the site?

When delivery vans full of goods first arrive at the warehouse, including from 1,200 independent businesses, they are sent through the parcel identifier machine. Tony said: "Instead of an employee having to scan every single unit that's in a box, the box goes down this conveyor, each scanner scans the box and it knows what's inside. It receives it into our inventory so that it's now available to the customer. It puts a tracking label on it and then sends it down the conveyor where it goes to one of the receive lines."

The parcels are then inspected by an employee to ensure it's the correct item and it isn't damaged, before it's stowed onto the shelves. Tony said: "There will be rare cases where we'll get something into this warehouse that we can't sell.

"It could arrive to us slightly damaged, damaged to the point where you wouldn't want to pay full price for it, or maybe it still has value - in that case we'll try our hardest to resell it somehow. If we can't resell it, we'll recycle it or donate it."

Christmas trees, baseball bats, suitcases, football tables, record players, mini grills and a steam mop were just some of the items that were waiting to be picked and packed by staff during our time at the warehouse. But instead of the same type of item being stored together - they are put onto the shelves at random.

This helps to ensure that employees have an "optimal pick path", which saves time and means they don't have to walk as far to find them. Hand held scanners help staff find the items which are then loaded onto crates and sent to be packed.

Once each item is placed in the right box and taped up, it travels on a conveyor which swiftly scans, labels and weighs it. The parcels are then separated by location and loaded onto a van to go to a sort centre and out for delivery.

The Knowsley site holds millions of products and sends out tens of thousands to customers every day. On the week of Black Friday, which falls on November 25, hundreds of thousands of parcels are expected to leave the warehouse.

Amazon has previously faced criticism from workers over the conditions at some of its warehouses and the lack of breaks for staff. When the ECHO asked Tony about this, he said: "We're absolutely committed to safety, it's the first thing we talk about in the morning as a leadership team. It's the fore of everything we're trying to do in the building - set up a safe, modern environment.

"The role of technology is important but also the role of making the process smooth for the associate so their experience is positive.

"There is just nothing to the idea that there aren't breaks or that associates don't have a good experience. That's actually everything we want from them is tell us how we can make it even better."