Antarctica. Snow, ice, penguins, polar explorers, and lasers… Wait, what?

Laser welding and laser engraving machine were sent in freezing conditions to help workers of the Bellingshausen science station, and for that equipment was modified. These laser machines are the first of that type shipped to Antarctica.

Bellingshausen

Smoke-blue sky, murky surface of the ocean, and the black tail of a cetacean rising above it. Squelch through the water, and splashes scatter, and behind them in the distance on the grey-brown and snowless shore, there are square-like houses of dirty-beige colour and a few screaming-red buildings that look like alarm buttons on the dim wall.

That is what the view on the Bellingshausen was like on the day of the cargo boat's arrival.

In this little city, no more than thirty people dwell. However, it’s just fifteen of them most of the time. Not far away there are stations from China, Chile, Uruguay, Argentina, Brazil, Peru, South Korea, and Poland. It’s normal here to pay each other a visit or even go to the neighbour doctor for consultation. Different languages, political systems, and prejudices do not come to these cold shores; if you want to survive here—be friends and help each other.

The Bellingshausen is the most northerly Russian station. All year, geophysical, meteorological, and oceanological research takes place, and the global warming problem is being studied.

The climate here differs from the rest of Antarctica. The Bellingshausen is not placed amongst snowy deserts with dry wind and rare precipitation; it suffers from high humidity, which makes -20℃ feel like -40℃. And it really suffers; because of the salt and moisture, the corrosion rules in here and consumes everything made of metal, from stairs and piles to hangars and equipment. It is possible to order a replacement from the mainland, but the waiting time will be long.

Laser machines

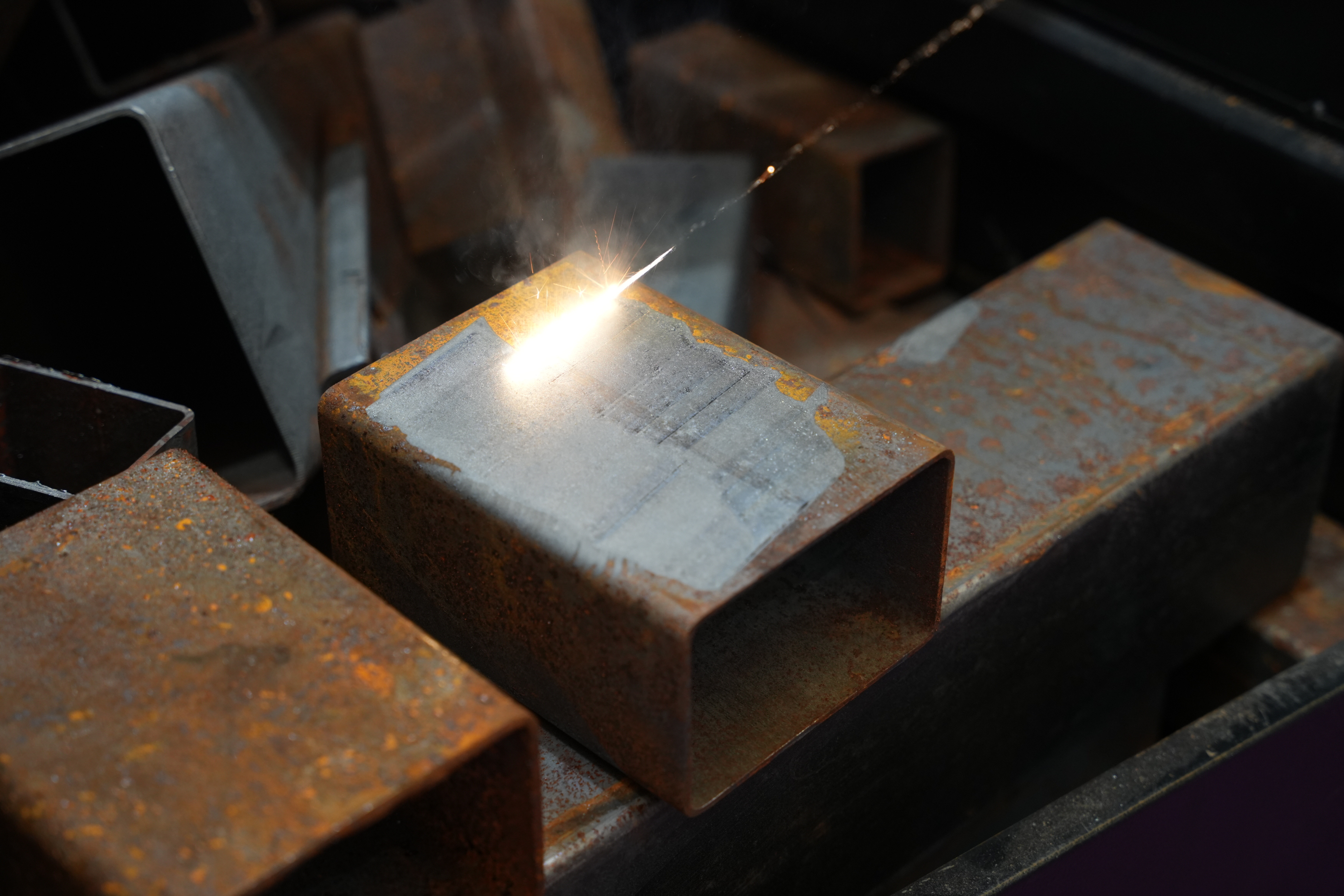

This is the moment when they come to the stage. A 4in1 laser welding machine and fiberlaser engraver headed their way to Antarctica to fight corrosion.

“Literally this year, we realised that technology has advanced significantly, and laser welding will save us time and money compared to using electrodes, which can run out at any moment. Sometimes it happens that they weren’t loaded or weren’t placed, the container fell and broke, or they got lost,” comments Andrey Mirakin, the employee of the Antarctic Scientific Research Institute. That’s true; electrodes are always required when working with ordinary welding, and they are not always available.

A Wattsan 4in1 laser welding machine with 3000 W of power has four functions: welding, cutting, cleaning, and cleaning welds. With its help, polar explorers plan to carry out repairs of damaged equipment and buildings and mount, for example, new ladders.

A laser welding gun that is sent to Antarctica has two mirrors. They change the laser’s movement trajectory, allowing it to set forms, or patterns, which imitate the hand movements of the welder when using traditional methods like TIG. That eases the working process. Additionally, laser welding equipment is 4–5 times faster than TIG or MIG.

The gun itself is from Relfar: Wattsan engineers tested and compared the abilities of several laser heads, as well as their stability, and based on the results, Relfar was chosen.

“At Bellingshausen Station, due to corrosion, the paint on inventory numbers constantly comes off all our equipment. Any cargo that arrives must have some form of marking. This is the main purpose for which we will use the marking machine,” says Andrey Mirakin about Wattsan FL TT with 30W MOPA JPT.

MOPA technology was specifically chosen for harsh Antarctic surroundings since it provides more precise results: MOPA allows it to have a high peak value, better control over the frequencies, and control over pulse width. That results in a wider colour palette and, what’s more important for this situation, long-lasting marking of metals, plastics, and other materials.

Both machines were modified by Wattsan factory engineers to meet climate conditions on station; construction was made waterproof, especially electrical parts, so the equipment would work even at -30°C.

The first one

That’s what these laser machines from Wattsan shipped to Antarctica became. For the laser industry, it’s another step on the way to even further expansion of its capabilities and applications.

Nowadays, lasers are actively evolving in general. As observed, more and more powerful machines are being developed, for example, a metal cutting laser machine from Raycus with 200 kW of power, laser welding machine that can process plastic, and new sources for cutting both metallic and nonmetallic materials. Wattsan itself launched a new 6000 W laser cleaning machine.

Watching how a laser behaves in new conditions like the Antarctic winter may help to improve this technology in the future and make it even more stable.

Challenge

“Before sending the equipment to Antarctica, we conducted extreme tests over several months. We tested the machines’ ability to operate and their performance duration at temperatures down to -30°C, in rain, and strong wind. Additionally, resistance to sand and other external factors was tested,” remarked the leading engineer of the Wattsan development department.

Jinan Wattsan Technology is a Chinese manufacturing company supplying laser and CNC machines to over 50 countries and now is literally present all over the world. The company willingly takes orders that require personalisations, and this project with Antarctica was an interesting challenge for engineers. It was held through one of the official company dealers, Lasercut.

Training for participants of the 70th expedition was also performed through the dealer: in one day they learnt how to operate the marker and the laser welding machine, as well as the switching between functions. It’s easy to change functions on this kind of machine—only a replacement of the nozzle and lens module is required.

“We clean, cut, and weld! The expedition can now operate efficiently! Our engineers’ eyes lit up with excitement,” said Mirakin later.

The company promised to report on the equipment’s condition in Antarctica while searching for new borders that it would be eager to cross. Who knows, maybe one day some laser machine will be sent to a space station, not an Antarctic one.