If there's one area of cycling I love in a disproportionate and nerdy way, it's the rich history of innovation that stretches across the sport. The first slant parallelogram derailleur, the first aero extension bars, and the first clincher tyre all opened up new dynamics in racing and a world of opportunity for consumers.

While we celebrate the trailblazers across the sport's history, some of the most innovative efforts have never escaped the confines of various R&D teams.

I've toured dozens of factories over the last seventeen years in this industry, and been prohibited from photographing or even mentioning some of the most absurd innovations.

Not so at SRAM headquarters, though.

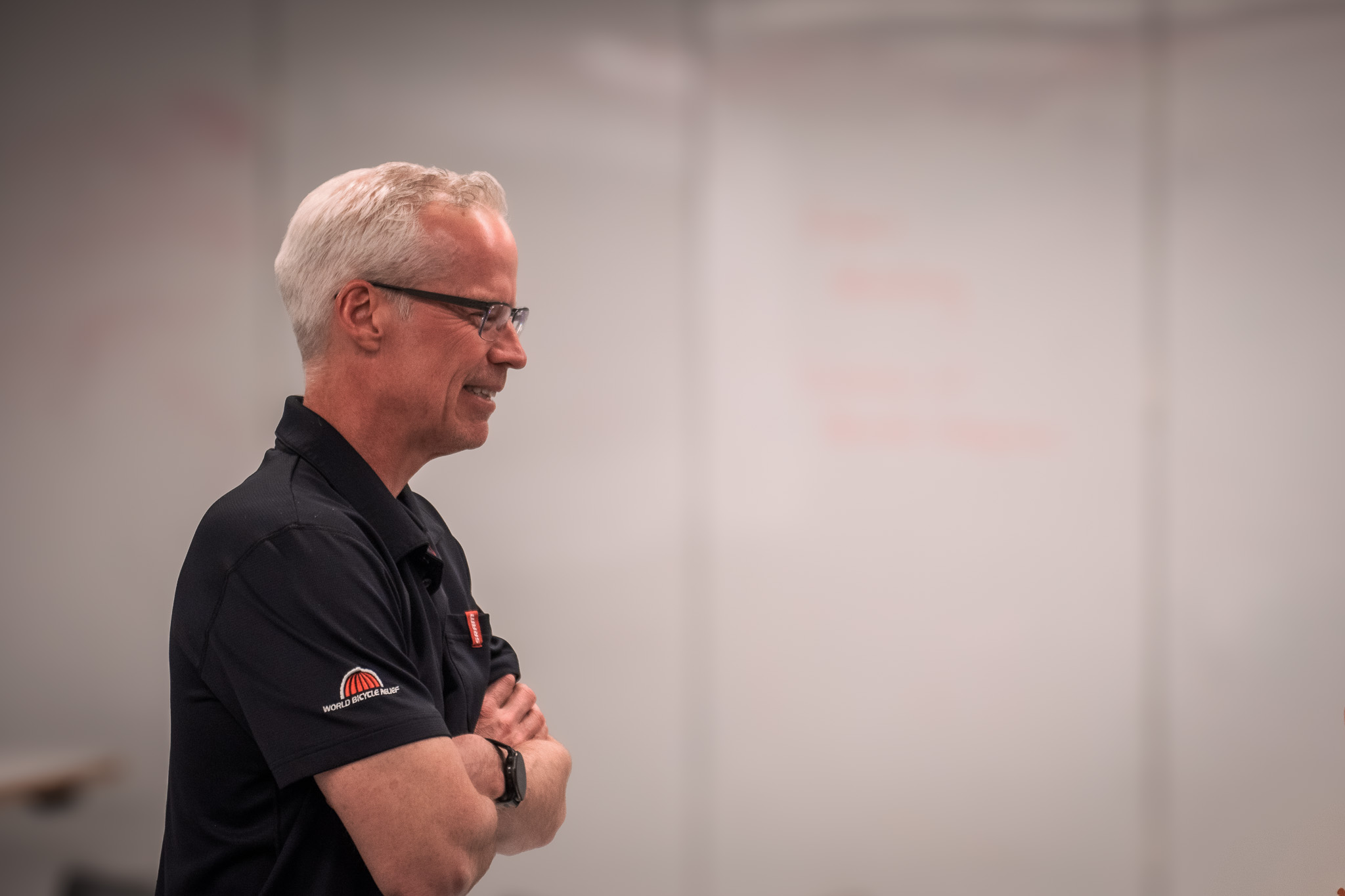

Visiting the Chicago base of the American groupset giant in the spring, Kevin Wesling – Director of Advanced Development at SRAM – gives us a detailed snapshot of his history of innovative experiments in the Advanced Development team.

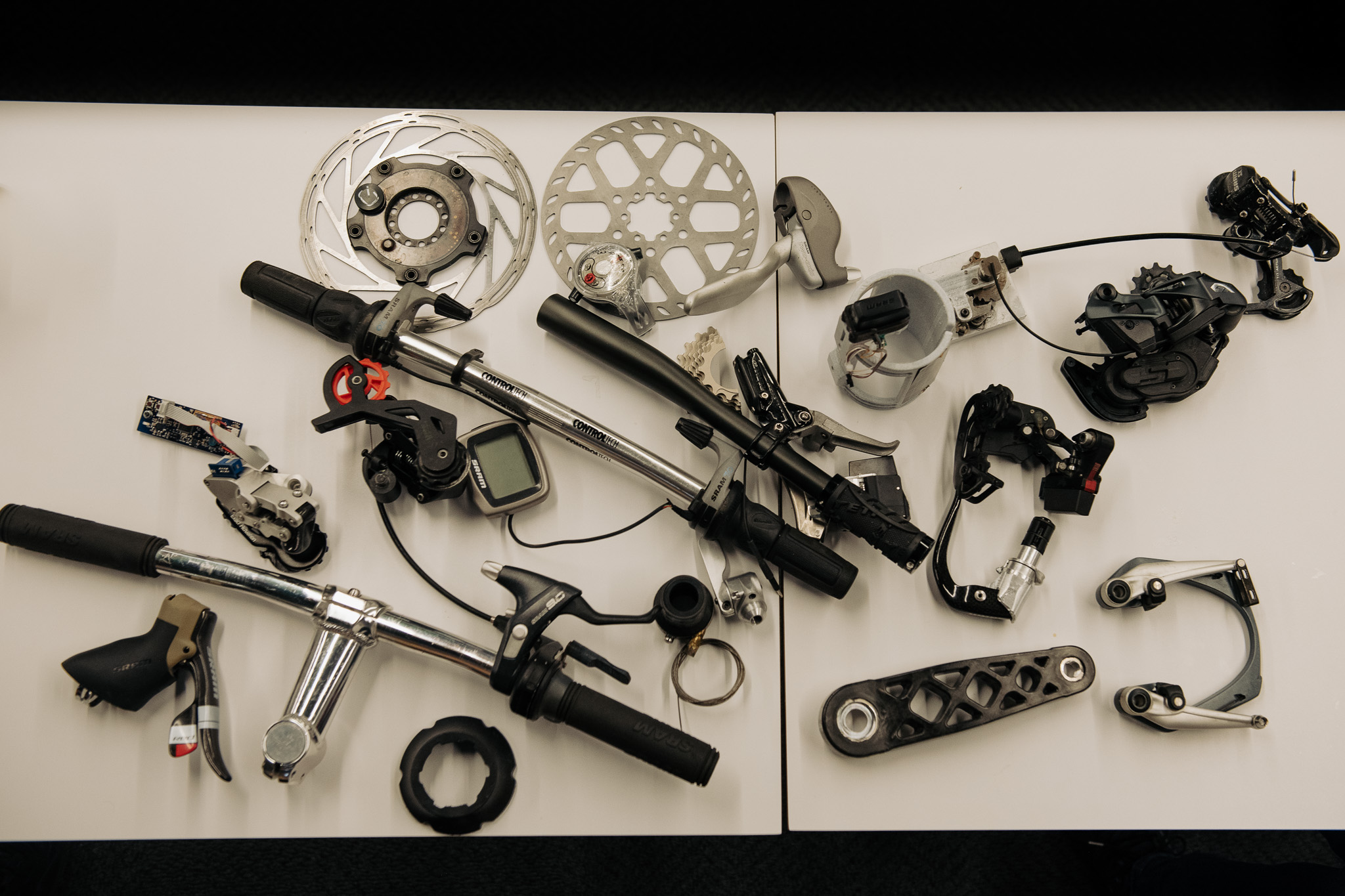

"We got to take that dumb idea and move it off the list, because sometimes you just have to make it to confirm that it's no good," Wesling says with a modest smile as he pours components out onto a white table in the company's main meeting room.

Arrayed on the table is a living history of SRAM’s ambitions, successes, and near-misses – some are overtly wild in nature, while others are subtly divergent.

A story with a twist

SRAM's roots lie in shifting, so it's fitting that a gripshift system is one of the first that Wesling shows us.

"When we started at SRAM, all we made were twist shifters," Wesling explains. "This was our whole world. And we avoided triggers forever – we were like, no, twist shifters are better because you can shift ten gears at once. It’s faster."

In those days, gear indication was the dominant, albeit relatively random, battlefield. Shimano had visible index windows, so Sram battled to create something better.

“The most important thing was gear indication,” says Wesling. “That was the big fight – who could do the best gear indication. So we did a bunch of projects that were a little crazy. We even made a big display that told you what gear you were in.”

Wesling shows us a floating dial which looks a little like a Christmas cracker present.

“It actually just kind of hung out there in space, like your cables went to it and came out of it and just kind of floated in front of you.”

A slightly more sophisticated solution sits next to it, a large digital dial that shows gear - perhaps more in tune with what we'd expect from the AXS era.

"I didn’t put a battery in there, I don’t know if it still works, but this was a big display that would tell you what gear you’re in," Weling says.

Shifting innovation in the early days had other near-misses, some rather elegant.

In the late 1990s, SRAM acquired Sachs - a German brand famous for upright, utility and trekking bikes. SRAM's AD team created a raft of products to complete the new portfolio.

“We created five products for the trekking industry,” he says. “The Sparc e-bike hub, the DualDrive hub, the SmartBar, the i-Brake… and the Two-Axis Brake.”

The brake lever effectively moved in parallel with the squeezing of the hand. "It was about natural ergonomics," Wesling explains.

"It was one of the things I did as a young engineer," he recalls fondly, but alas, it never saw commercial success. "It was too clever for its own good,” Wesling argues.

Tapping away

Of course, the failures came alongside major steps forward, which landed. Along the way, of course, iterations fell by the wayside in the name of progress.

“If you want to launch a road group, you can’t start with a twister,” Wesling says. “We didn’t have a road shifter, and we needed one.”

“We even made a twister that had a lever on it,” he recalls. “You’d release with a trigger. We called it the Twigger, I’m not making that up.”

It was that crossbred engineering leap that led to the formation of the DoubleTap concept.

“This guy in our group, Brian Jordan – he’s probably the most prolific inventor we’ve got – came up with this concept: pull a little to release, pull a lot to shift. One lever, two actions.”

“When we first brought the idea up,” Wesling laughs, “one guy said, ‘That’s the stupidest idea I’ve ever heard.’ But once people rode it, they got it. Once it’s on the bike, it’s money.”

Scepticism quickly abated when the models were put to use in practice. "We put that on a bike, and we made prototypes, then we made a road shifter version. And once people rode that around the office, we launched the whole of Force and Rival."

While DoubleTap was a resounding success, one of the brand's failures almost stands out as a more daring innovation. was particularly compelling.

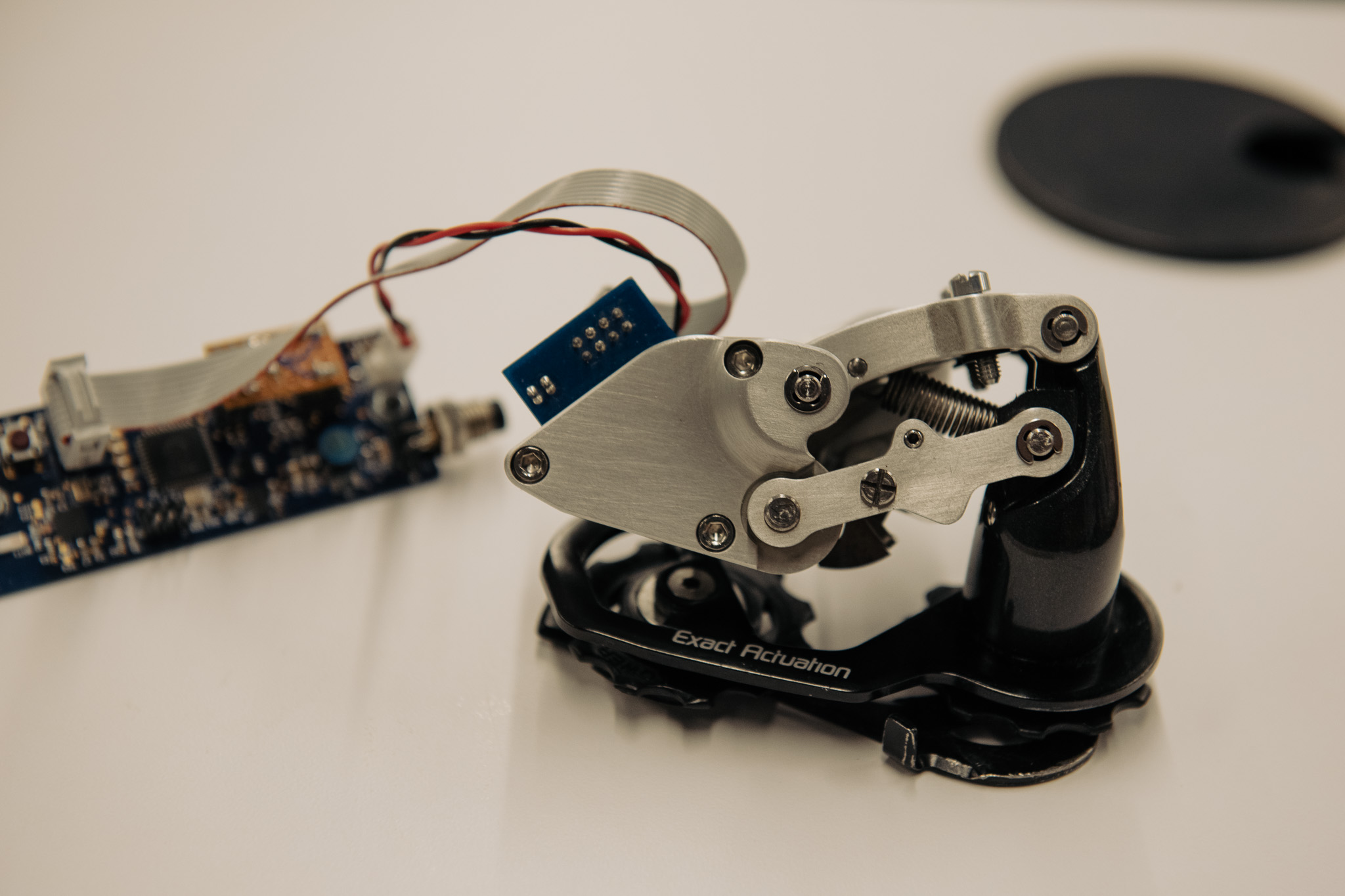

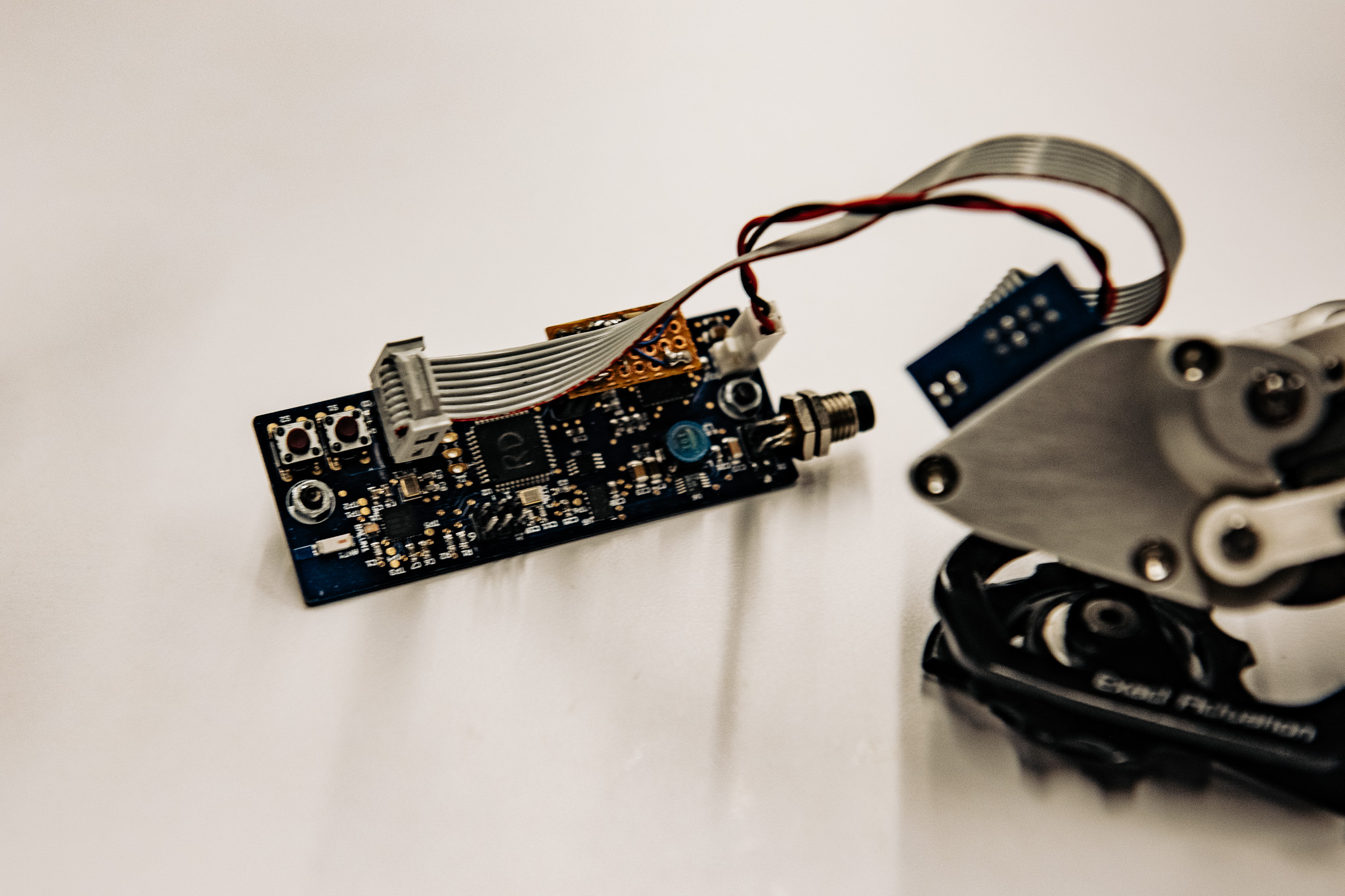

“This is probably one of the first eTap derailleurs ever made,” Wesling says, lifting an industrial prototype, with the circuit board totally detached. "We prototyped the battery, we changed the latch – you can see the old design in the patents.”

Wesling points to a newer iteration and the handsome but monolithic battery sealing. The product development is mapped out in front of us, and the iterative journey to the first generation of eTap is a characterful one.

Among the iterative steps, though, one derailleur stands out.

“Everybody kept asking, ‘Why can’t you make it self-charging?’” Wesling explains. “So we did.”

He points to a much larger and more complex rear derailleur.

“This whole section had a generator. As you rode, it charged the system. You didn’t use a normal battery; you used a super-cap that could power about fifty shifts. It worked. But when it was charging, it drew four watts instead of one.

It seems like an innovation too good to have shelved, but the clash or performance and power loss made it a non-starter. "Too much drag," Wesling explains. "So it never made sense to scale.”

Long game

A characteristic element of the Advanced Development team is that amongst its successes, lots of the key innovations were long, often high-risk solo projects that culminated in major steps forward.

“We started Flight Attendant about six years before it launched,” Wesling explains. “We hired one guy in California and just let him go. He worked on it for five years, iterating at his own pace, outside the pressure of regular production schedules.”

Flight Attendant may be lesser known to road cyclists, but it's a huge part of SRAM's RockShox suspension system, and its ability to deploy an automatic, sensor-controlled suspension system that adjusts in real time.

“The early version tried to do everything from one sensor,” he says. “Just accelerometers and gyros. But we learned you need pedalling data too. So we added a pedalling sensor. You go through iterations, find what works, what doesn’t.”

When the project finally became official, Wesling's team handed it to the wider global engineering team to turn it into a real-world product.

“The first four or five years were just one or two people,” Wesling says. “After that, it was 10 or 15, and the cost went up fast. But that’s how it should work. Our group proves the concept. Then we let the big teams make it real.”

Spectacular failures

Sometimes the greatest innovation surfaces when brands stretch a little too far, and often beyond the realms of practical usability. In the case of SRAM's AD team, that certainty seems evident.

The most overt example jumps out to me from the array of products, a brake rotor with a Quarq power meter on it.

"We even did a brake power meter,” Wesling confirms. But my initial impression was a little removed from the reality - the product was never meant to be public-facing.

"The goal wasn’t to sell it, but to learn." He continues. “We developed it mostly for the brake team. It measured braking power directly – like a hub power meter, but for deceleration. The Quarq unit read torque and rotation, but we had to increase the data rate a hundred-fold to capture it. It was just a development tool.”

Of the wild and dysfunctional wonders, one truly reigns supreme. SRAM's voice-activated gear shifting helmet.

“The number of people that asked for voice-activated shifting,” Wesling laughs. “So we made one. Took a week.”

Welsing explains that the team rigged a standard helmet with a microphone, a speaker, and a wireless transmitter connected to an eTap system. The prototype recognised two commands: “peanut butter” to upshift, “jelly” to downshift.

“People were riding around the office yelling ‘Peanut butter!’ ‘Jelly!’,” Wesling recounts. “Afterwards, everyone agreed it was a dumb idea. But it was great, because we could take it off the list. Sometimes you have to build something to prove it doesn’t belong.”

“It was pretty funny. And then after they wrote it, they're like: yeah, that's a dumb idea. Which was great, because we got to take that dumb idea and move it off the list.

"Because sometimes you just sometimes you have to make it to confirm that it's no good.”

One of the most endearing elements of the AD team is how affectionate Wesling is for the team's creation, both the successes and failures.

“Every engineer in AD has a box like this,” he says. “Old ideas, broken things, projects that never went anywhere. And every so often, someone pulls one out, dusts it off, and it becomes relevant again. You never know.”

Of course, amid the failures have been resounding successes. Alongside eTap, DoubleTap and Flight Attendant, the Universal Derailleur Hanger (UDH) is one of the AD department's more humble achievements.

“The full mount derailer came first, and then UDH was created to Trojan Horse the concept into the market," Welsing tells us.

"The UDH by itself is still a great idea, that's why. And the engineer who worked on that is a German engineer named Henrik Braedt, you know, in the AD group. And I say that when he dies, his gravestone should say UDH on it, because he's saved the world, like, millions of hours of looking for new derailleur hangers, right?"

The AD department has a lot to celebrate alongside its more spectacular flops. For a journalist used to seeing polished prototypes and carefully curated creation myths of celebrated products, a glimpse of the less glamorous failures makes for a refreshing change.

“Flight Attendant, DoubleTap, eTap – all of those came from this same process,” Wesling says.

Perhaps a spirit of innovation and willingness to fail has played a part in those commercial successes.

“We’re lucky. We get to experiment without pressure. And if something doesn’t work, that’s okay. We learn. That’s the point.”