The newest ship in the Disney Cruise Line (DCL) fleet, Disney Destiny, departed the Meyer Werft shipyard in Germany at the weekend for Fort Lauderdale in Florida, ahead of its maiden sailing in November.

Themed around heroes and villains, the ship features Spider-Man on the stern and a superhero Minnie on the bow.

But much of the work that went into its construction may never actually be seen by passengers.

The Independent went behind the scenes with DCL designers – known as Imagineers – to discover how they build the much-loved vessels.

Planning and concept

Most of the imagery you see on Disney’s ships are years in the making.

Walt Disney Imagineers have been dreaming up plans for the current Wish class ships since 2017. The first, Disney Wish, was launched in 2022, which was followed by Disney Treasure in 2024 and Disney Destiny, which will be launched later this year.

A fourth, unnamed, Wish class ship is also currently in development at the Meyer Werft shipyard.

Claire Weiss, senior creative director at Walt Disney Imagineering, says: “We really wanted each ship to have a unique signature identity.

“That was something a little bit new for us creatively. Our classic ships were beautiful and had very strong visual language. We thought we would experiment a little.”

Read more: Behind the scenes at the float-out of Disney Destiny

It all starts with a theme. Claire says: “We initially just had motifs – things like enchantment or adventure.

“We talk about the words and the emotions at the beginning and how they fit together. If they feel different, they're going to look different. They're going to tell different stories.”

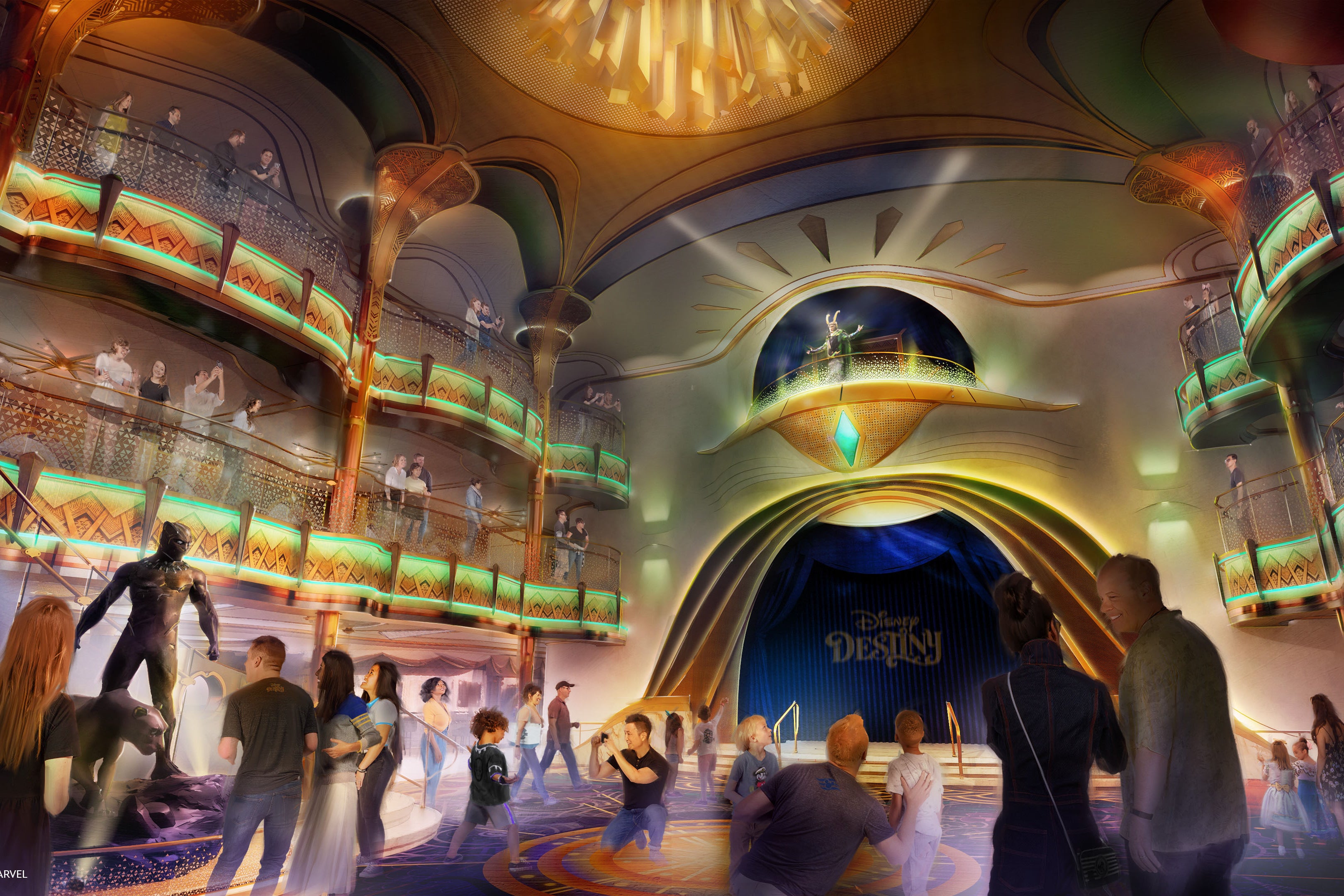

It was this process that resulted in Destiny’s 17-foot tall Spider Man, plus the bronze statue of the Black Panther in its Grand Hall. The ship also features a Doctor Strange-themed bar, while guests will be entertained with a Hercules theatre show.

Hidden elements for superfans include Mickey Mouse designs in the carpet, plus patterns from the Black Panther suit in the railings.

Claire says: “Everything we do has narrative significance.

“We want the guests to see and enjoy it, but it also gives us a lens through which to make creative decisions. We feel as if we're being true to the story.”

The planning stage alone can take up to two years. Initial preparations include the creation of sketches and 3D images, followed by negotiations with the shipyard to determine how realistic the plans are. Once the designs are confirmed, building contracts are agreed.

The building stage

Disney Cruise Line is using the Meyer Werft shipyard in Germany to build its Wish class ships, where more than 2,000 people can work on construction each day.

The start of the process is marked with a steel-cutting ceremony, where the first piece of the ship is created. There is also a “keel-laying” that involves placing a coin under the bottom of the ship for good luck.

.jpg?trim=0%2C0%2C0%2C0)

Some parts, such as the AquaMouse water coaster, are lifted onto the ship in parts and built on deck.

Other sections are constructed in a nearby facility. Rather than being built on the ship, the cabins are pre-fabricated, with every aspect of the room – including the televisions, headboard art, mattresses and sofas – already installed.

The production line completes one cabin every 25 minutes.

Philip Gennotte, a senior project manager executive at the company, explains: “We want the staterooms to be as good as they can be from a quality point of view, so it makes sense to design them in a way that it can be repetitive.”

The process is not the same as building a theme park for one crucial reason: cruise ships move.

Philip says: “About 60 megawatts of power is created inside the ship. You could power a small city with that.”

The power might be metropolis-level, but so too is the ship’s capacity – bustling with passengers and crew.

In addition to the public areas, those that work on the ship also need spaces to live and rest.

Crew-only facilities include a barber, a buffet and bar – that guests never get to see.

.jpg?trim=0%2C0%2C0%2C0)

Philip says: “These are all the bubbles that all need to be integrated into the ship.

“Designed, integrated, planned, procured, sourced, built, then commissioned. That's the complexity that we're dealing with.”

Construction can take two years before the ship is ready for its final stages.

Float-out to flag exchange

A cruise ship first touches water in a float-out ceremony, seen as a major development milestone.

The ship is usually pulled by a tugboat in a process that takes two hours.

After the float-out, the ship then goes through a conveyance, which involves stress-testing it under bridges and on riverbeds. If it passes, then it’s through to sea trials.

Philip says: “We want to see the speed she can reach, is she quiet? Does she move properly?

“There are seven days of sea drills, where crew live on board to test everything out.”

The ship is then returned to the dockyard for the final decorative touches ahead of an official handover.

Philip adds: “It’s like buying a car – we sign papers and take ownership.”

The handover is marked with a flag exchange, where the German flag of Meyer Weft will be swapped for DCL’s and the flag of the Bahamas, where the ship is registered.

Philip says: “Once the ship is in our hands, we will sail across the Atlantic to prepare for our first voyages from Fort Lauderdale.

“We will use that crossing for training, making sure everything from the crew to the performance areas are ready for guests.

“We don’t want anyone on board until it is perfect.”

Royal Caribbean reveals plans for fifth mega cruise ship

Virgin Voyages changes cruise fares and signals Portsmouth exit

Are theme park rides safe? Safety experts explain

Discover the best cruise for you – from northern lights to Norwegian fjords

Stormy seas and stand-up: My week on Virgin Voyages’ UK comedy cruise

Disney Cruise Line offering huge discount ahead of new ship launches

6 best family cruise deals for last-minute October half-term holidays in 2025