Figure 1: A multidisciplinary team assesses a rapid prototyping partner in a digitally integrated factory, leveraging data-driven decisions to accelerate product development and mitigate supply chain disruptions.

Introduction

Product development teams are under immense pressure to transform concepts into testable prototypes at unprecedented speeds in today's competitive market. The selection of an inadequate rapid prototyping service might lead to a significant delay in projects, blowing budgets, and even the misdirection of the entire development process due to the performance of mediocre prototypes. This mostly happens due to an ineffective selection process where the decisions are made based on price alone or depending on promises without critical evaluation of technical capability, quality systems, and stability in their supply chain.

This guide offers a strategic evaluation framework to enable decision-makers to assess a potential partner systematically and make sure that selected providers could not only deliver speed but also prove to be reliable contributors toward the product development cycle. The sections below break down five dimensions intrinsic to evaluating rapid prototyping partners.

What are the critical capabilities beyond basic machining?

But to move beyond the very basic question of "can they machine it?" demands a deep dive into the breadth of provider technical ecosystem. Capable partners can support multiple processes — like mixing 3D printing with CNC machining — to perform different validations as required by the stages of development. Additionally, digital manufacturing workflows such as automated quoting and instant DFM analysis are integral for superior operational efficiency. Standardized processes-in accordance with the merits proposed by organizations like International Aerospace Quality Group (IAQG)-are fundamental for repeatable, high-quality prototypes.

1. Evaluating Technical Diversity and Process Integration

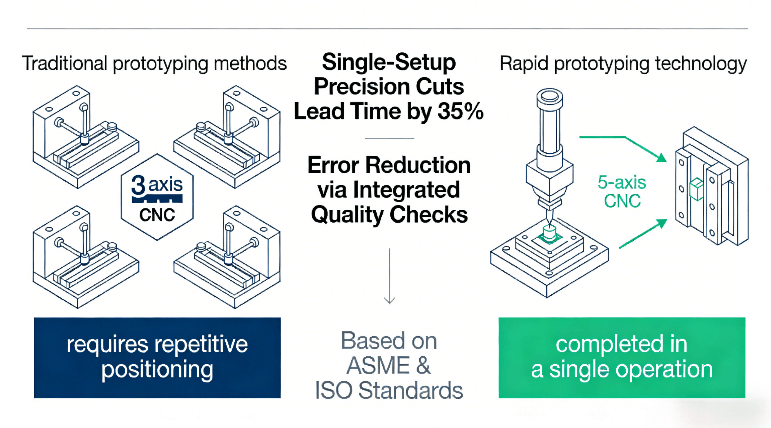

The partner with several manufacturing technologies--ranging from SLA and SLS to multi-axis CNC machining--can choose the best process possible for the needed prototypes. True integration means allowing such seamless transitions between these technologies based on the phase of the project, specific material needs, and intended function.

Figure 2: Advanced 5-axis CNC machining enables single-setup precision, reducing prototyping time by 35% and minimizing errors compared to traditional multi-step methods, as per industry benchmarks.

2. Facilitation of Operations by Digital Infrastructure

Some key differentiators are digital manufacturing tools. Instant quoting engines and digital DFM reports that provide early feedback on manufacturability issues can significantly compress lead times. This assures transparency through a digital thread, reducing iterative delays and thereby directly contributing to accelerated development.

How Can You Quantify the Real Cost and Value of a Prototyping Project?

To understand the true cost, it is beyond just unit price comparisons. Decision-makers must evaluate the total cost of ownership, including material selection, design complexity, tolerance requirements, and post-processing. A detailed rapid prototyping CNC quote should give as clear a breakdown as possible to enable accurate comparisons. Indeed, according to resources from the American Society of Mechanical Engineers(ASME), the importance of accurate cost estimation at the very beginning of the project cannot be overestimated to keep the budget and enhance value analysis.

1. Breaking Down the Components of a Prototyping Quote

A transparent quotation will separate out the raw material cost, machine time, setup, and any secondary operations of surface finishing or inspection. This makes it easier to determine where potential optimisation could occur to fit within budget, such as material substitution or changes in design, while still not affecting the critical features.

2. Analysing Cost Drivers and Added Value Services

Some of the factors that affect the cost for rapid prototyping CNC services include expedited lead times, material certifications, and the inclusion of inspection reports. Partners offering value-added services, like proactive DFM analysis, may be a bit higher upfront in their quote but deliver more value over the long term by avoiding costly redesigns and ensuring first-time-right quality.

Why is Quality Assurance a Non-Negotiable Factor in Rapid Prototyping?

Functioning prototypes depend on a strong quality assurance system. Risk associated with the project is lowered because parts will be in accordance with specifications repeatedly. A complete quality loop-from first-article inspection to final verification-provides documented proof of compliance. Finding a partner with an internationally recognized standard like ISO 9001 for quality management and AS9100D in the case of aerospace verifies independently that a partner respects strict process control.

- In-Process Inspection and Metrology: Advanced partners use on-machine probing and portable CMMs for in-process checks. The result of this real-time monitoring is early detection of deviations, allowing corrections during machining that reduces scrap. Measurement integrity is assured by the use of calibrated equipment traceable to national standards.

- Risk Management through Documenting and Traceability: Complete documentation, including material certifications and inspection reports, provides full traceability. This is crucial for prototypes destined for regulated industries, as it aids in achieving compliance and smoothing the road to production. The quality culture of a supplier, witnessed by their certifications, is the first determinant of reliability.

What Does a Strategic Partnership in Prototyping look like beyond a transaction?

The difference between a transactional vendor and a strategic partnership is the depth of collaboration: a true partner contributes to the product development strategy through expert input such as providing DFM analysis, which optimizes designs for cost, performance, and manufacturability. Great communication, transparency, and project management are hallmarks of this relationship. Teams wanting to understand more about how design optimization impacts prototyping success can take advantage of external resources as well, such as this expert CNC prototyping guide.

1. Proactive Communication and Engineering Support

You should be looking to a partner that will assign an engineer specifically to review your design and suggest design alternatives for difficult features; a partner that will maintain open communication channels throughout the program. This proactive approach makes the supplier an extension of your R&D department.

2. Long-Term Alignment & Scal

A strategic partner will have been aligned with your long-term objectives, such as the ability to scale from prototype through to low-volume production. It provides continuity, so there is no need for re-qualification of a new supplier, thus saving time and potential risk associated with the critical stages of scaling up.

How to Future-Proof Your Prototyping Process with Sustainable and Scalable Practices?

Forward-looking firms must also take into consideration a company's dedication to environmentally sustainable production practices and supply chain optimization. Such practices as having a high material utilization rate, recycling metal scraps and cutting fluids, and operating in a fuel-efficient manner are but a few factors in achieving environmental sustainability goals. The scalability of a company from prototype manufacture through pilot production or scaled production is a significant aspect of supply chain sustainability.

- Environmental Practices and Material Efficiency: Inquire about the waste reduction and sustainable materials use policies of the provider. An efficient nesting computer program that makes maximum use of materials to cut down expenditures and the environmental effects; prototypes built according to the corporate sustainability strategy.

- Building a Scalable and Resilient Supply Chain: This is the kind of partner that is able to adjust according to the demands and is able to deliver even at peak periods. This scalability is an essential part of risk mitigated and optimized supply chains that help future-proof your product development process.

Conclusion

Selecting the appropriate rapid prototyping vendor is much more than just a one-dimensional comparison based on cost and cycle time; rather, having such an analysis capability helps firms transform prototype development from necessary pain to powerful competitive advantage. It helps firms accelerate innovation while reducing risks associated with innovation.

FAQs

Q1: What is the difference between Rapid Prototyping and traditional CNC machining of the Prototype?

A: The basic difference exists in intentions and methods. Rapid prototyping CNC is all about doing things fast in order to test a design for quick feedback, whereas conventional CNC machines are perfect for creating a component with utmost precision as an individual entity. The decision depends on whether a project requires rapid design iteration or final-part precision from day one.

Q2: How can I compare quotations offered by various providers of rapid prototyping services?

A: Request a detailed breakdown with regards to the materials,machine time, setup charges, and post-processing costs. Provide all vendors an identical CAD file and specifications. Review what's included in the quality assurance section of the quote. If the quote is significantly lower, this could indicate shortcuts taken with regards to the material testing, for example, and could become an issue down the road.

Q3: Why are certifications such as ISO 9001 and AS9100D significant in seeking a prototyping service provider?

A: These certifications are an independent endorsement of the fact that the supplier has an effective quality management system in place. While ISO 9001:2015 signifies a commitment to quality, the AS9100D standard signifies a commitment to quality with more rigorous risk management and traceability, which is a necessity when it comes to the prototype of regulated industry products.

Q4: What would be the benefits of choosing a supplier who can perform both prototyping and low volume manufacturing?

A: This means massive improvement in terms of supply chain optimization and continuity. Now there is no need for this hassle of re-qualifying a new supplier, not to mention the time and effort, when you are scaling up and do pilot testing. Since your partner already has an understanding of your design intent, scaling up operations is much smoother and hence more reliable.

Q5: What impact may proper design for manufacturability feedback have on prototyping success?

A: Proactive analysis of DFM is very effective. This technique helps us to identify possible manufacturing problems (features difficult to machine and unnecessary tolerance values) before the start of manufacturing. These problems, when taken care of early, can result in reduced machining time and minimized manufacturing costs.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, and has many years of experience in rapid prototyping and low-volume production for aerospace, medical devices, and consumer electronics industries.They are proficient at offering high-precision manufacturing techniques.To get a precise cost estimate along with a free DFM analysis for your project, you can refer to their page about rapid prototyping services.