Selecting the appropriate 3D printing technology for your project can significantly impact both the quality of the final product and the efficiency of the production process. At OurPCB, we offer a range of 3D printing services, each with its unique advantages suited for various applications. This guide will help you make an informed decision by explaining the key factors to consider and matching the best 3D printing technology to your project’s needs.

Understand Your Project Requirements

The first step in choosing the right 3D printing technology is to thoroughly understand the requirements of your project. These may include:

- Purpose of the object: Are you creating a prototype, a functional part, or a model?

- Material needs: What kind of materials are suitable? Metals, plastics, or resins?

- Detail and accuracy: How precise do the details need to be?

- Production scale: Is this a one-off print or a mass production?

Understanding these aspects will guide you toward the most suitable printing technology.

Types of 3D Printing Technologies

There are various 3D printing methods, each suitable for different applications. Here are some of the most commonly used technologies:

1. Fused Deposition Modeling (FDM)

FDM is one of the most popular and affordable 3D printing techniques. It uses a thermoplastic filament that is heated and extruded layer by layer to create an object. FDM is ideal for low-cost prototypes and models that don’t require extremely high detail or strength.

- Best for: Simple prototypes, hobby projects, and low-budget designs.

- Materials used: PLA, ABS, PETG, and more.

2. Stereolithography (SLA)

SLA uses a laser to cure liquid resin into solid objects. It’s known for its ability to create highly detailed and smooth surface finishes, making it suitable for intricate designs and models requiring precision.

- Best for: Detailed prototypes, medical models, and jewelry.

- Materials used: Photopolymer resins.

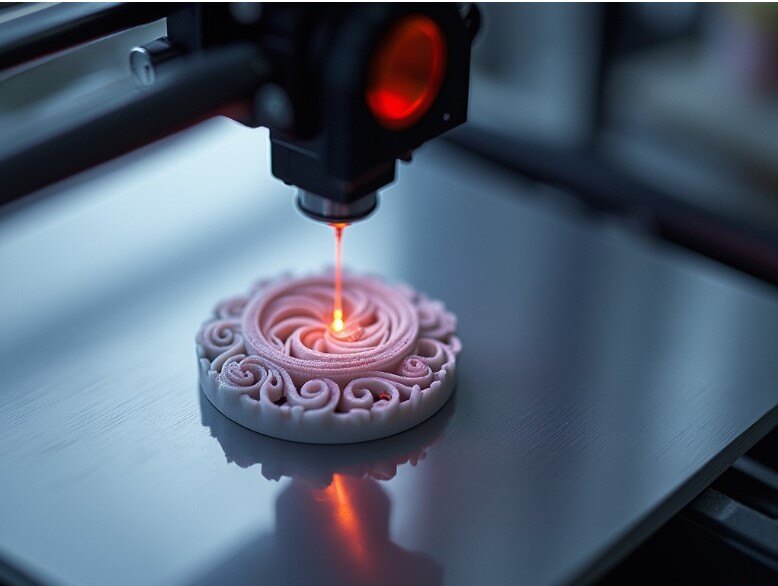

3. Selective Laser Sintering (SLS)

SLS works by sintering powdered material (often nylon) using a laser. This technology is ideal for producing durable, functional parts with complex geometries that wouldn’t be possible with traditional manufacturing methods.

- Best for: Functional parts, complex geometries, and high-strength applications.

- Materials used: Nylon, composites, and metal powders.

4. Digital Light Processing (DLP)

DLP is similar to SLA but uses a digital projector screen to flash a single image of each layer all at once. It’s faster than SLA and offers similar high-quality finishes.

- Best for: Detailed prints requiring quick production.

- Materials used: Resins.

5. Multi Jet Fusion (MJF)

MJF is an advanced technique that uses a fusing agent and detailing agent to selectively melt powdered material, layer by layer. It’s known for producing high-quality, durable parts quickly and efficiently.

- Best for: Functional prototypes, complex assemblies, and small-batch production.

- Materials used: Nylon, TPU, and composites.

Material Selection

Choosing the right material is as important as choosing the printing technology. Your choice of material will affect the strength, flexibility, and appearance of your final product. Some of the most common 3D printing materials include:

- PLA (Polylactic Acid): A biodegradable thermoplastic commonly used in FDM printing. It’s great for prototypes and display models but is not suitable for high-stress applications.

- ABS (Acrylonitrile Butadiene Styrene): Stronger than PLA and often used for functional parts. It is more heat-resistant but can be harder to print.

- Nylon: Flexible and durable, ideal for functional prototypes and mechanical parts.

- Resin: Used in SLA and DLP technologies, resin produces high-detail models but may require post-processing.

- Metal powders: Commonly used in SLS and MJF, these provide strength and durability for functional parts.

Precision and Detail

If your project requires a high level of detail or intricate designs, you will need to choose a technology that can deliver precise results. SLA, DLP, and MJF are excellent options for high-detail prints, while FDM may not be suitable for intricate work.

Additionally, consider the layer resolution—the thinner the layers, the smoother and more detailed the object will be. Technologies like SLA and DLP offer finer layers than FDM, making them ideal for precision work.

Production Speed and Cost

Balancing speed and cost is a crucial factor. For example, FDM is cost-effective and fast for low-detail prototypes but may not be suitable for complex parts. On the other hand, SLA and SLS offer higher precision but take longer and are more expensive.

For small-scale production runs or when time is critical, MJF or DLP might be your best choice, as these technologies are faster without sacrificing quality.

Consider Post-Processing Needs

Some 3D printing technologies require extensive post-processing, such as cleaning, curing, or sanding, to achieve the desired finish. SLA and DLP prints often need curing, while FDM prints might require sanding to smooth out visible layer lines. Before deciding on a technology, think about how much time and effort you are willing to invest in post-processing.

Project Budget

Budget constraints will also influence your decision. FDM is one of the most cost-effective technologies, while SLA, SLS, and MJF tend to be more expensive due to the materials and processes involved. Always consider your project’s budget in conjunction with other factors like material strength and production speed.

Conclusion

Selecting the right 3D printing technology requires careful consideration of your project's specific needs, including the material, precision, speed, and budget. Each technology—whether FDM for affordability, SLA for precision, or SLS for strength—has its strengths and is suited to different applications. Taking into account factors like post-processing requirements and production volume will ensure that you choose the most efficient method for your project, ultimately leading to better results and optimal performance for your end product.

.png?w=600)