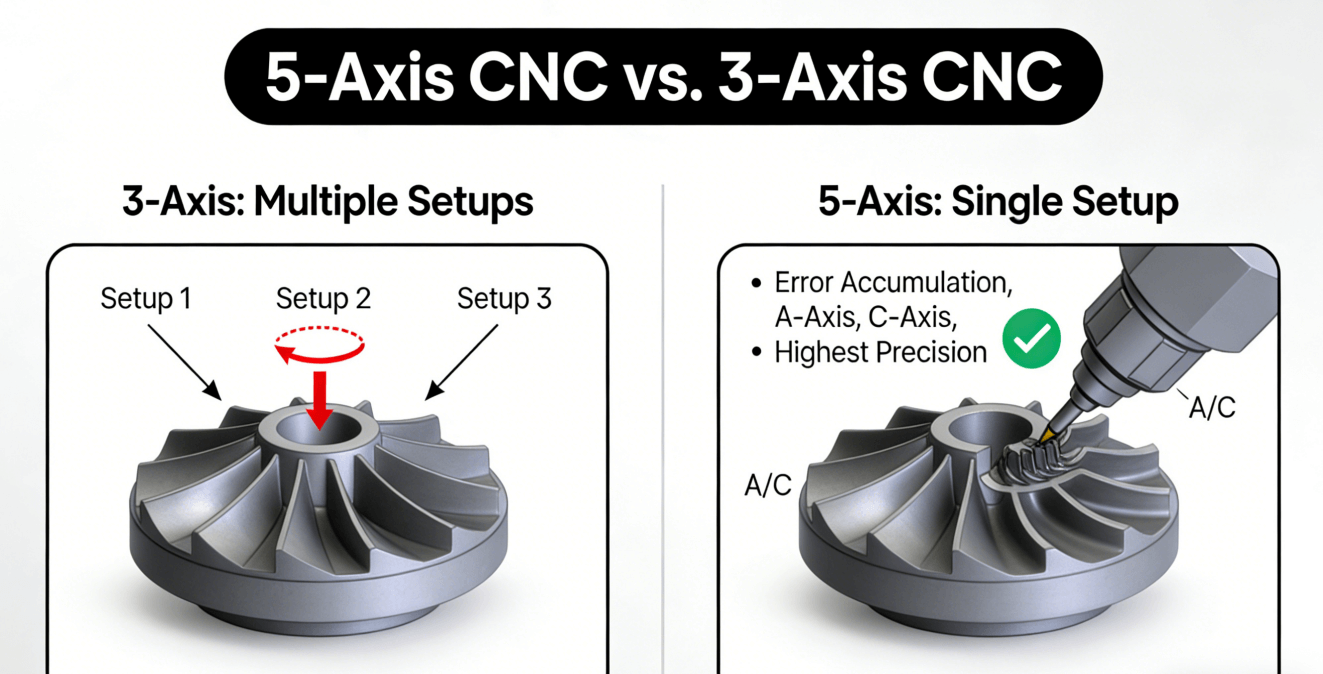

Figure 1: High-precision machining of a complex part in a single setup with 5-Axis CNC technology.

Introduction

In critical industries such as aerospace engineering and medical technology products, the process of producing parts with complicated geometry is quite challenging. Conventional 3-axis CNC machining is inadequate in this regard and results in inaccuracy, increased setup time, and high rework rates. The basic drawback of the conventional process is its inefficiency in executing multi-angle cutting tasks simultaneously.

This hinders the freedom of design. 5-Axis CNC Machining is identified as the most effective technique and has the capability of performing multi-axis simultaneous movements that make it possible to generate complicated parts within a single setup. This method is highly accurate and efficient. This paper proposes an evaluation of the basic concepts and benefits of this revolutionary technology.

What is Five-Axis CNC Machining? How Does it Differ from Conventional Machining?

Figure 2: Illustration of how 5-axis CNC machining eliminates error accumulation by completing complex geometries in one clamping.

The Core Principle: Five Axes of Motion

The CNC machining process, known as 5-Axis CNC Machining, has five axes that can be independently programmed. In addition to the conventional X, Y, and Z linear axes, it includes two rotating axes, typically named A and B. The A-axis is set to turn around the X-axis, and the B-axis rotates around the Y-axis. This configuration enables the cutting tool or workpiece to tilt and swivel, allowing the tool to approach the workpiece from virtually any angle without manual repositioning.

Paradigm Shift from 3-Axis Constraint

- Moving from Multiple Setups to Single Setup Completion

The major demerit of 3-axis machining is revealed when manufacturing complex components. These scenarios require multiple manual re-clampings to access different sides, with each new setup introducing positioning errors that accumulate, leading to a loss of accuracy across the part's features. In contrast, 5-axis CNC machining completes the entire component in a single clamping, eliminating the cumulative errors associated with repeated refixturing. - From Approximate Contouring to Accurate Surfacing

During the machining of complex 3D curved surfaces, such as impellers and turbine blades, 3-axis CNC machines tend to produce a stairstep pattern or approximate tool paths, impairing surface finish and dimensional accuracy. A 5-axis CNC machine dynamically adjusts the tool's orientation, maintaining the optimal cutting angle relative to the contoured surface. This capability, known as swarf or flank machining, produces superior surface finish, higher contour accuracy, and extends tool life.

The Foundation for Unprecedented Precision

This advanced functionality is the foundation for adhering to stringent geometric dimensioning and tolerancing (GD&T) standards. Understanding how 5-axis CNC works — through continuous toolpath control — is essential for meeting the tight tolerances specified in standards like ASME Y14.5 . By enabling precise control over orientation and position, 5-axis machining directly satisfies complex tolerance requirements, particularly for profile and orientation, making it a cornerstone of modern Precision Engineering .

Why Is 5-Axis CNC Essential for Manufacturing Complex Geometries?

For Complex Part Manufacturing, 5-axis CNC technology has evolved from an optional requirement to an essential one. Its critical nature stems from its ability to address the fundamental challenges inherent in complex geometries.

First, it solves the fixturing bottleneck problem from the ground up. Components like aerospace turbine blades and medical implants have twisted surfaces and tight internal tolerances. A traditional 3-axis approach would necessitate multiple setups, a process prone to inaccuracies. A 5-axis machining center can produce the entire component in one setup, ensuring critical positional accuracy between all features.

Secondly, it provides the only efficient method for high-precision curved surface processing. When creating molds, optical lenses, or artificial joints, the tool must maintain a specific angle relative to the surface normal to avoid gouging and achieve optimal cutting conditions. The dynamic tool orientation of a 5-axis CNC machine accomplishes this perfectly, producing surfaces with exceptional finish and accuracy unachievable with traditional methods.

For instance, in machining aircraft parts, 5-axis CNC machine parts allow for seamless contouring, as detailed in industry guides . This ability empowers designers to adopt more aerodynamic or bio-compatible organic shapes. Therefore, when engineers seek custom 5-axis CNC parts, they are pursuing the unification of design freedom, functional integrity, and manufacturing feasibility .

What Are the Key Benefits of 5-Axis CNC in Reducing Time and Cost?

The implementation of 5-axis CNC machining provides direct and significant benefits in time and cost optimization, yielding a substantial competitive advantage .

Drastic Reduction in Total Cycle Time

- Process Consolidation and Reduced Non-Cut Time

The greatest time savings come from consolidating multiple 3-axis operations into a single 5-axis operation. The time required for repeated fixturing, tool changes, and machine setup is dramatically reduced. This slashing of non-productive time can shorten the total production cycle by 30%-40% for complex components, enabling a faster response to market demands. - Optimized Cutting Parameters and Higher Material Removal Rates

By dynamically adjusting the tool's angle, 5-axis machining enables the use of shorter, more rigid tools. This permits higher feed rates and increased depths of cut, boosting the material removal rate and compressing the actual cutting time and overall production schedule.

The Strategic Value of Investment

While the initial investment is higher, the comprehensive benefits delivered offer an attractive return. It not only lowers the per-part cost but also enhances a company's ability to undertake high-value, complex projects. Manufacturers certified toISO 9001and IATF 16949 ensure that the efficiency of 5-axis machining is combined with a systematic quality management system, reliably translating advantages into long-term value . Therefore, obtaining an accurate 5-axis CNC quote that includes a total cost-benefit analysis is a critical step in understanding the full benefits of 5-axis CNC .

How Does 5-Axis CNC Enhance Quality Control and Precision?

5-axis CNC technology is a powerful tool for Precision Engineering, and its integration with modern quality control systems elevates quality control in CNC machining from final inspection to integrated process assurance .

The "single setup" paradigm is the first line of defense for precision. It eliminates the cumulative errors introduced by repeated refixturing, ensuring high internal consistency among all geometric features of a part. This means critical characteristics like the true position of holes and profile tolerances are inherently more accurate .

Furthermore, advanced 5-axis CNC machines can be integrated with on-machine probing systems. High-resolution probes can automatically measure key part features during or after machining, creating a "machining-inspection" closed loop. If deviations are detected, the system can automatically compensate for tool wear, preventing a batch of non-conforming parts. This real-time monitoring aligns with ISO 9001 requirements, minimizing deviations .

Finally, a systematic quality management system amplifies these advantages. Adherence to standards like ISO 9001 ensures a complete process from First Article Inspection (FAI) and Statistical Process Control (SPC) to final inspection with Coordinate Measuring Machines (CMMs). The high consistency of parts produced with 5-axis CNC makes inspection more efficient and data more stable, establishing full traceability from design to finished part .

What Industries Leverage 5-Axis CNC for Innovative Applications?

5-axis CNC machining, with its unparalleled flexibility and precision, serves as a core technology driving innovative designs across several leading industries .

- Aerospace: This sector demands components that are lightweight, strong, and capable of withstanding extreme environments. 5-axis CNC is used for monolithic machining of large airframe structures, engine casings with complex internal channels, and high-precision airfoils. It enables the creation of single parts from high-performance alloys, replacing multi-part assemblies to reduce weight while dramatically improving structural integrity

- Medical Devices: From complex orthopedic implants to specialized surgical instruments, biocompatibility and surface finish are paramount. 5-axis CNC can machine anatomically correct, complex surfaces from materials like medical-grade titanium or PEEK, ensuring perfect fit and function. Its flexibility makes it ideal for low-volume 5-axis production runs of custom implants or specialized tools

- Automotive (High-Performance and Electric Vehicles): In the pursuit of lightweighting and performance optimization, 5-axis CNC is used for machining engine blocks, lightweight chassis components, complex transmission housings, and intricate battery enclosures. It supports a seamless transition from rapid prototyping for design validation to the production of high-performance components.

These diverse 5-axis CNC applications share a common thread: they require the translation of highly complex designs into physical reality with extreme precision and consistency .

How to Select a Reliable 5-Axis CNC Machining Service Provider?

Selecting the right 5-axis CNC machining partner is a critical decision for project success. Several key criteria should be evaluated:

- Certifications and Quality Systems are Foundational:

The provider should possess robust quality management system certifications, such as ISO 9001 (Quality Management), IATF 16949 (Automotive), or ISO 13485 (Medical Devices). These certifications are proof of standardized, traceable processes. For services certified to ISO 13485, refer to professional 5-axis CNC machining services - Technical Expertise and Equipment Portfolio:

Evaluate the provider's machine brands, models, and their technical capabilities. Advanced CNC systems, high-precision spindles, and rotary tables are the foundation of accuracy. Equally important is the expertise of their engineering team in programming complex parts, optimizing multi-axis toolpaths, and handling challenging materials - Proven Experience and Communication:

Request case studies or examples from your industry or of similar part complexity. A reliable provider will understand your design intent, functional requirements, and potential manufacturing risks, offering valuable Design for Manufacturability (DFM) feedback. Clear and professional communication is essential for a smooth project flow

Conclusion

In summary,5-axis CNC machining fundamentally addresses the challenges of precision, efficiency, and flexibility in Complex Part Manufacturing through synchronized multi-axis control. It consolidates multiple operations into a single setup, drastically reducing production lead times and overall costs while enabling advanced in-process monitoring and systematic quality management. From aerospace to medical sciences, it has become an indispensable core technology for realizing innovative designs and ensuring critical performance.

Author Bio

This article was contributed by a precision manufacturing expert from LS Manufacturing. The company holds ISO 9001 and IATF 16949 certifications, ensuring every part meets the highest standards. Get a Custom Quote Now!

FAQ

Q: What is the tolerance achievable with 5-axis CNC machining?

A: 5-axis CNC typically holds tolerances as tight as ±0.005mm, ideal for high-precision applications like aerospace components. Advanced machines coupled with ISO 9001 processes ensure consistency .

Q: How does 5-axis CNC reduce production lead times?

A: By eliminating multiple setups, 5-axis CNC completes complex parts in one operation, cutting lead times by up to 50% compared to traditional methods .

Q: Can 5-axis CNC handle both prototyping and mass production?

A: Yes, it supports rapid prototyping for design validation and scales to high-volume production with minimal tooling changes, ensuring cost-effectiveness .

Q: What materials are compatible with 5-axis CNC machining?

A: It works with metals (e.g., aluminum, titanium), plastics (e.g., PEEK), and composites. Material selection is optimized for strength and thermal properties .

Q: How is quality verified in 5-axis CNC processes?

A: Quality checks include on-machine probing, CMM inspection, and FAI reports, aligned with standards like ASME Y14.5. Providers with ISO certification add an extra layer of reliability .