Manufacturing downtime remains one of the most expensive problems in the industrial world. Whether it’s a food production line or a textile factory, delays due to equipment issues, operator errors, or unstructured knowledge often result in massive operational and financial losses. That’s the problem LineWise.io is tackling—by turning tribal knowledge into a scalable digital brain for frontline teams.

Founded by entrepreneurs Tanachart Kujareevanich, Napon Tang-aromsuk, Zhichu Ren, and Wenbo Zhang, LineWise is building an AI co-pilot that helps factory workers troubleshoot and resolve issues faster. Using advanced vision-language models and a growing library of digitized SOPs, machine logs, and historical fixes, LineWise empowers even less experienced operators to perform like seasoned experts.

Designed for the Realities of the Factory Floor

LineWise wasn’t built in a vacuum. The idea emerged directly from time spent on factory floors—where the founders saw firsthand how unstructured knowledge and inconsistent training created bottlenecks in daily operations. Instead of building another dashboard, they asked: What if factory workers could instantly tap into the experience of their best operators—anytime, anywhere?

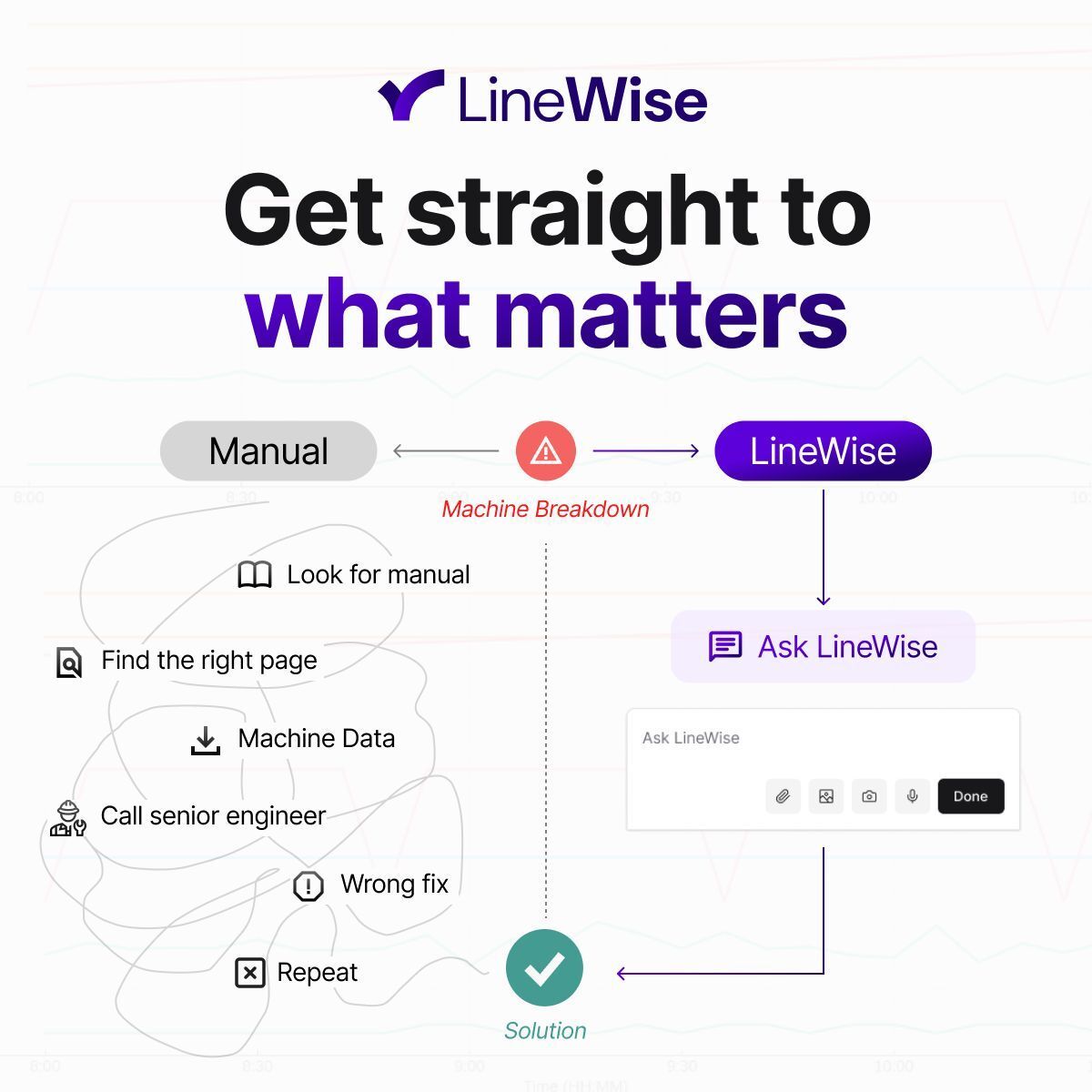

That question led to a vision: creating a generative AI system that learns from real video footage, machine manuals, and frontline feedback to generate accurate, step-by-step guidance for resolving breakdowns. LineWise does more than just serve up documentation—it understands context, prioritizes likely root causes, and helps operators navigate complex fixes in real time.

Meet the Co-Founders

James (Tanachart) Kujareevanich: Systems Thinker, Strategic Builder

James Kujareevanich is one of LineWise’s driving forces, bringing a rare mix of technical intuition and operational insight. A graduate of MIT’s Sloan School of Management, James developed a deep appreciation for the systemic challenges facing industrial operations—particularly in sectors where uptime, quality, and safety are paramount.

Before MIT, James worked as a consultant at McKinsey Operations and saw firsthand how fragile many factory processes were—highly dependent on tribal knowledge and undocumented workflows. That experience planted the seed for LineWise: What if frontline expertise could be captured and applied as systematically as machine data?

At LineWise, James serves as CEO, leading the overall direction of the company and its go-to-market strategy. He works across product, sales, and customer success to ensure the company stays aligned with the needs of its industrial partners. His focus is on scaling LineWise’s impact across factories by building a solution that’s both technically robust and deeply practical.

Napon Tang-aromsuk: From Process Detail to Product Vision

Napon Tang-aromsuk brings a rare combination of frontline manufacturing insight and entrepreneurial experience to LineWise. A biotechnology graduate from Imperial College London, she has worked in food manufacturing, contributed to a health tech startup, and founded a women’s health tech company. This diverse background equips her with both the operational understanding needed to navigate complex production environments and the agility required to scale early-stage ventures. At LineWise, she serves as Chief Operating Officer (COO), leading operations, customer success, and implementation.

Napon is the bridge between factory floors and scalable software. She works closely with operators to extract tribal knowledge—often undocumented and highly situational—and translates it into structured, real-time guidance delivered through LineWise’s SaaS platform. Her goal is to ensure that institutional expertise becomes a repeatable, systematized part of daily operations, accessible across shifts, sites, and skill levels.

The Team Behind the Machine

LineWise is a product of interdisciplinary collaboration. Zhichu Ren, who earned his Ph.D. from MIT, brings deep technical expertise in computer vision and robotics, helping design LineWise’s core multimodal architecture. Wenbo Zhang, an engineer and builder with experience in industrial automation, leads infrastructure and platform reliability. Both play key roles in translating cutting-edge research into rugged, real-world applications—especially in environments where internet connectivity, device constraints, and operator variability are the norm.

From Pilot to Platform: Building the Factory OS

LineWise’s broader ambition is to become a foundational layer for factory intelligence. The tool already integrates with SCADA systems, maintenance software, and industrial sensors, offering co-pilot troubleshooting agent that evolves with every use. Operators can upload a video of a recurring issue, annotate fixes, and instantly generate a structured SOP. Managers can use analytics to track where errors occur most often and refine training accordingly.

Early adopters in the U.S. food and beverage sector are reporting reduced downtime and improved shift consistency. From high-pressure homogenizers to tray sealers, LineWise’s AI has been deployed across a variety of assets—and it’s learning every day.

What makes LineWise different is its human-first approach. The founders aren’t trying to automate away jobs—they’re building tools that elevate the work of people on the floor. And as manufacturers face growing pressure to boost output, reduce costs, and transfer knowledge between generations, LineWise offers a timely and powerful solution.

Learn more at https://www.linewise.io/

Youtube: https://www.youtube.com/@LineWiseAI

Linked in: https://www.linkedin.com/company/linewise