An affordable robotic arm can bring practical automation to classrooms, workshops, and small production lines without breaking the bank. Look for models that balance price, precision, and ease of use—enough accuracy for your tasks, intuitive controls, and just the features you need, so you’re not paying extra for functions you’ll never use.

Overview of Cost-Effective Robotic Arms in Modern Automation

Robotic arms have revolutionized automation accessibility across multiple sectors. Manufacturing facilities now use $1,000-$5,000 robotic arms for tasks like pick-and-place operations, quality control, and assembly functions, which previously required $50,000+ industrial robots.

Today's budget-friendly options deliver impressive capabilities:

|

Solution Tier |

Typical Features |

Common Uses |

|

Entry-level |

3–4 DOF, light payloads, intuitive software |

STEM education, hobby projects |

|

Mid-range |

4–6 DOF, moderate payloads, open-source ecosystems |

Research labs, small businesses |

|

Professional |

6+ DOF, higher payloads, advanced programming interfaces |

Production lines, prototyping, QA |

These budget-minded arms provide real automation capabilities without the complexity or overhead of legacy systems. Schools integrate entry-level models into STEM curricula for hands-on learning. At the same time, small firms deploy desktop-sized units to handle repetitive tasks such as sorting, packaging, and light assembly, freeing staff for higher-value work.

What makes today’s affordable options especially powerful is the pairing of lower total cost of ownership with flexible, user-friendly programming. This combination lets teams customize workflows across diverse applications without requiring specialized engineering expertise, accelerating innovation while keeping expenses predictable.

Key Features of an Affordable Robotic Arm

Robotic arms combine essential capabilities with budget-friendly pricing. These key features determine their functionality and value across various applications.

Performance and Precision

Performance in robotic arms centers on accuracy and consistency in task execution. Look for arms with high-torque servos or stepper motors that provide precise movements.

The number of joints (degrees of freedom) directly impacts flexibility and task capability. Industrial models typically offer four to six joints, enabling complex operations like assembly, welding, and material handling. Higher precision allows for repeatable positioning, which is essential in manufacturing applications.

Ease of Use and Programming

User-friendly interfaces transform a robotic arm from a complex machine into a practical tool. Seek models with intuitive programming options, such as drag-and-drop interfaces, visual programming environments, or straightforward SDKs.

Programming flexibility matters—some arms support multiple languages, including Python, C++, and specialized robotic languages. Other convenient features include teach-by-demonstration capabilities, where you physically move the arm to program positions, saving time for newcomers to robotics.

Safety Features

Safety mechanisms protect both users and equipment when working with robotic arms. Essential safety elements include emergency stop buttons, collision detection systems, and torque limiting to prevent damage during unexpected contacts.

Look for arms with software safety boundaries restricting movement to predefined safe zones. Some models incorporate force-feedback systems that detect resistance and adjust operations accordingly. Physical guards or light barriers protect educational or small business environments where multiple people might interact with the equipment.

Flexibility and Versatility

Versatile robotic arms adapt to various tasks without requiring complete system changes. Interchangeable end effectors—such as grippers, suction cups, welding torches, or specialized tools—expand functionality for different applications.

Mounting options also affect versatility, with some arms designed for tabletop use while others can be wall-mounted or ceiling-mounted. The working envelope (reach) and rotation ranges determine what tasks the arm can perform within its space. Models that easily integrate with other automation equipment offer greater long-term value.

Cost-Effectiveness and ROI

The true value of an affordable robotic arm extends beyond its purchase price. Calculate potential ROI by examining the arm's productivity gains, reduced labor costs, and improved quality control.

Consider ongoing expenses like maintenance requirements, power consumption, and software update policies. Some manufacturers offer modular designs allowing incremental upgrades rather than complete replacement. Training resources provided by vendors can significantly reduce implementation time and costs, making certain affordable models more economical over their operational lifespans.

Trade-Offs When Choosing an Affordable Robotic Arm

Selecting an affordable robotic arm involves balancing several crucial factors to get the best value for your investment. Each trade-off directly impacts the arm's functionality and suitability for your application needs.

Performance vs. Cost

Robotic arms typically offer lower payload capacities around 5 kg or less, while premium models handle 10+ kg loads. Lower-priced options often feature:

- Reduced precision and repeatability, affecting task accuracy

- Slower movement speeds and less smooth motion

- Limited reach, which works well in compact spaces but restricts workspace flexibility

When comparing affordable options, consider whether the performance meets your specific requirements rather than simply choosing the cheapest model available. The right balance depends on your application's precision demands and load requirements.

Complexity vs. User-Friendliness

Robotic arms balance technical capability against ease of use:

- Simpler programming interfaces make entry-level arms accessible but limit advanced functionality

- Basic models typically offer drag-and-teach programming or visual interfaces

- More complex options provide text-based programming but require technical knowledge

For beginners or educational settings, prioritize user-friendly interfaces with visual programming options. Small businesses might benefit from software with simple interfaces for basic tasks and advanced options for more complex operations as their needs grow.

Durability vs. Price

The construction quality of robotic arms varies significantly:

- Budget models: Often use plastic components and basic motors

- Mid-range options: Incorporate metal parts and higher-quality servos

- Higher-end affordable arms: Feature industrial-grade materials and components

Consider your usage frequency and environment when evaluating durability. Daily operation in production settings requires more robust construction than occasional educational use. Metal components and quality motors typically last longer, but increase the price point.

Safety Features vs. Investment

Safety features in robotic arms vary based on price point:

- Basic models: Manual emergency stops and simple collision detection

- Advanced affordable options: Torque sensing, automatic obstacle detection, and programmable safety zones

- All models: Require proper setup and risk assessment, regardless of built-in features

Don't compromise on essential safety features even when seeking an affordable robotic arm. The investment in adequate safety mechanisms prevents accidents and potential downtime. Balance your budget constraints with the necessary safety features for your application and working environment.

DOBOT’s Innovations

Among the manufacturers advancing accessible automation, DOBOT stands out for pairing precision engineering with user-friendly design. The company’s lineup shows how an affordable robotic arm can offer professional-level accuracy and versatility without compromising the essential features needed for education, prototyping, or light industrial use.

Affordable Robotic Arms by DOBOT

The DOBOT Magician stands out in the affordable robotics market with its 320 mm reach and 0.5kg payload capacity. It's priced competitively while maintaining professional-grade specifications suitable for education, small business applications, and hobbyist projects. DOBOT's design philosophy centers on balancing cost with capability, making automation accessible to users with limited budgets. Their arms feature intuitive interfaces that reduce the learning curve for beginners while providing enough sophistication for advanced users.

Technological Innovations

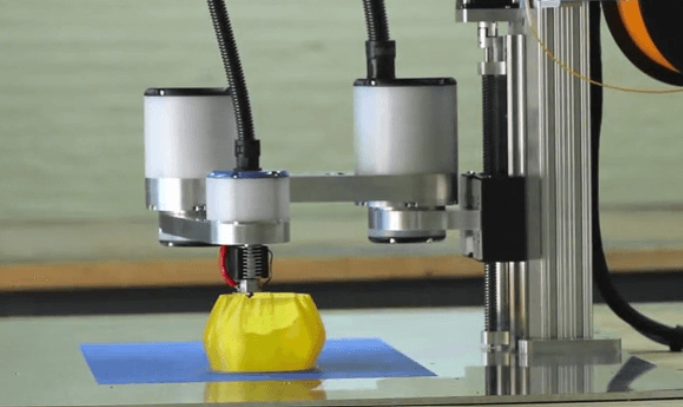

DOBOT's technological innovations focus on achieving premium performance in robotic arms. Their arms feature a repeatability of 0.2mm, enabling precise task execution for delicate operations. This accuracy level rivals more expensive industrial models at a fraction of the cost. DOBOT incorporates advanced motion control algorithms that compensate for mechanical limitations, resulting in smoother movements and higher reliability. Their modular design approach allows users to customize their robotic arm with different end effectors for varied applications—from 3D printing to laser engraving—maximizing versatility without requiring multiple specialized tools.

Conclusion

Choosing an affordable robotic arm means weighing its capabilities against your budget. Affordable models can deliver solid mid-range performance, offering 0.05 mm repeatability, modular end effectors, a 380 mm reach, and a 500 g payload, while industrial units like Standard Bots’ RO1 extend to 51 inches and lift to 18 kg.

Start by confirming the precision your applications demand. Then, match reach and payload requirements to the tasks at hand across entry-level, mid-tier, and production-grade categories. Finally, evaluate programming interfaces and safety features. An ideal affordable robotic arm delivers the technical specs you need without unnecessary extras, ensuring long-term value through higher productivity and ease of use.