While Brembo only has one racing factory in the world, the same can't be said of its factories that supply regular manufacturers. There are several all around the world, each busy making brake calipers, rotors, master cylinders, and more for seemingly infinite automotive and motorcycle applications. But only one is located in Bergamo, Italy, inside a rather architecturally awe-inspiring complex known as the Kilometro Rosso.

This is the factory where motorcycle brakes are made that I visited a short time ago, and where I got to live out all my best Sesame Street/How It's Made factory visit fever dreams, up close and in person.

If you've never visited a factory like this, one thing you might not expect is how incredibly pristine and precise everything is. From the moment you step through the door, everything is gleaming, inviting, and incredibly well-lit. I've been inside other automotive factories before, and if you're used to getting messy and grungy in your own garage, this is decidedly not that.

Since I'm sure someone's going to jump and mention it in the comments: Brembo, as you may know, owns a few other brands in the motorcycle braking component space. Both ByBre and J. Juan now nestle neatly under the Brembo umbrella; however, at the factory I visited, only Brembo-branded products are made.

Before embarking on the tour and asking questions to our heart's content, we first donned protective shoe covers since we weren't wearing steel-toed boots. After all, ATGATT means ATGATT, right? Right.

Lives On The Line

As you step onto one of the four Brembo OEM motorcycle caliper assembly lines at this factory, you instantly get a sense of precision, well-engrained routine, and the quiet confidence those things instill. Technicians working on the line appeared totally invested in and attentive to what they were doing. There's plenty of machinery in use, of course; as well as some robot involvement on the line, too; but very interestingly, it's done in ways that appear (to an interested but admittedly non-brake expert) exceedingly complementary.

Brake calipers, after all, are almost unbelievably important safety components. They can literally be the difference between life and death, and that's something that Brembo takes incredibly seriously. That's part of why accountability and traceability are built into each and every caliper that's produced, by means of a special manufacturing code that's assigned to each unit at the beginning of the process.

At each station, it's scanned, and the information about that unit is updated in a central database that keeps track of when each step in production was performed, as well as its quality assurance test results. Steps are checked both by machines and by human technicians, as well as recorded with multiple cameras along the line to corroborate that every step along the way has been done exactly as it needs to be.

Finally, at the end, there's a pressure test chamber that each and every Brembo OEM brake caliper goes through, including a helium test to check for leaks. Once the caliper has passed this final test, only then is it able to be released to be packed off for installation on a motorcycle.

Fascinatingly, one job that remains solidly in the hands of humans is hand-painting the carefully debossed Brembo logo that you're no doubt familiar with seeing on each unit. We spent a little bit of time at the painting station, where the master painter and an assistant painstakingly mixed and applied the paint to each caliper, not unlike an artist signing their finished work.

If you've ever worked with crafting ceramics and firing with glazes in your life, then you already know something about how heat can affect glazes and paints, and how consistency and amount of application can affect the look of the finished product. Apparently, getting just the right consistency and amount of enamel to perfectly and consistently fill out the Brembo logo on these calipers still remains a job best suited to skilled humans. (And honestly, GOOD.)

The Brake Development Process

Before a Brembo product gets to the point where it's being produced en masse on production lines, it of course, must go through a rigorous, multi-year development process. Here, multiple steps are involved.

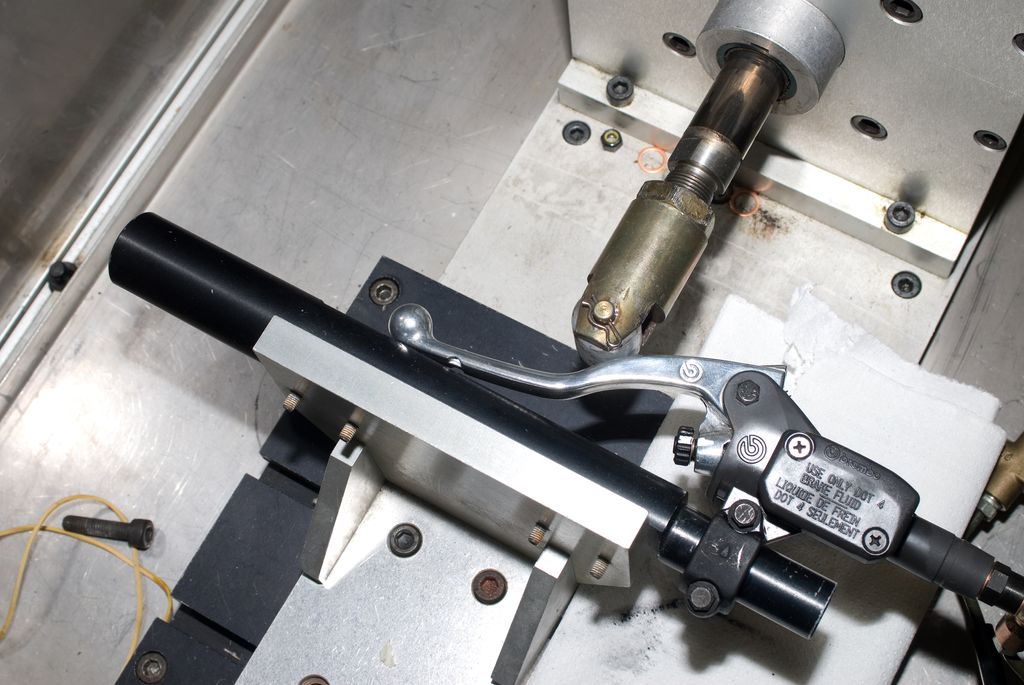

For brake calipers, there's a conditions simulator to put each caliper through every type of real-world situation where it might be used. And so, before it's ever released into the wild, it's undergone at least 200,000 motorcycle test cycles, on average. There's also a special motorcycle test bench that takes other systems on the motorcycle and how they might interact with the brakes into account. Different clutches, engine configurations, whether a bike is belt, chain, or shaft-driven; you name it, and Brembo has tested it.

Likewise, since the Bergamo Brembo OEM factory is located not very far away (seriously, it's a 10 to 15 minute drive or ride) from the Brembo Racing factory, employees in both locations are encouraged to chat and have interactions with one another. After all, you never know when an insight found on one side might be the answer to a question someone on the other team has. Sometimes, the nature of good collaboration is spontaneous, and breakthroughs can potentially benefit everyone.

In one part of the facility, there's a garage that's dedicated solely to test rigs, and it's full of different makes, models, and types of motorcycles (and sure, some cars and other passenger vehicles, too) that are set up to experiment with different conditions. Testing rigs with multiple sensors to gather data on what test riders experience are plugged into each machine, ready to capture an accurate representation of how the brake system component that's being tested is performing.

For motorcycle products specifically, Brembo's entire validation process can take up to two years to fully complete. As a rider who's been riding bikes with Brembo products for years (in fact, bikes in my possession right now have both Brembo and ByBre braking systems installed, depending on the bike), it's kind of comforting in a way. You might want your bike to stop with absolute quickness when you pull that lever, but development and testing aren't processes you want to rush.

Brembo's master cylinder lines are no less intricate and detailed their assembly, quality assurance, and tracking processes. Every step is performed with care, checked by cameras and human technician eyes alike, and traced throughout so there's a thorough record once again of everything that's been done. That way, if any issues do come up in the future, it should be a simple matter to trace every action taken.

It's kind of a heady thought to consider, the idea that the lives of millions of people around the world rely on your products every single day. That's not an overstatement, either; if you consider how many motorbikes alone use Brembo products (and that's before we start talking about passenger cars, or the company's more specialized racing division), it's a whole lot of responsibility that we're all placing on these comparatively small, intricate assemblies.

But it's clearly one that Brembo and the people working there don't take lightly. It's something I definitely find comforting, and I hope you do, too.