Attempts to utilize artificial intelligence (AI) systems are spreading through the world of sake brewing in Japan.

There is a deep-rooted image of sake brewing in which the experience of the toji -- a master brewer who supervises the process -- has great influence on the taste and quality of the alcoholic beverage. But those who are attempting to incorporate AI aim to have these systems learn the skills of the toji's methods, acquired from many years of experience, so that AI will be able to help produce high-quality sake.

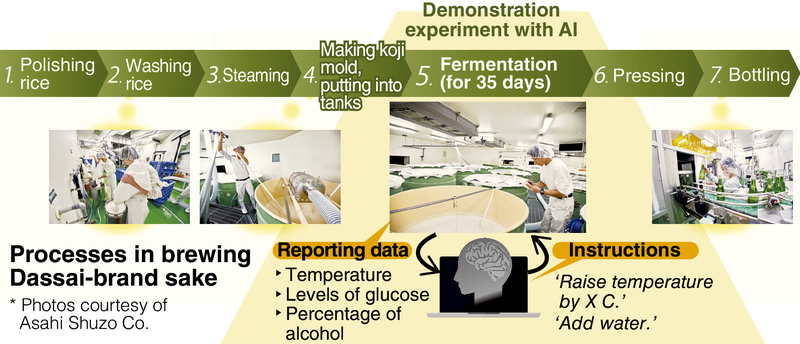

Yamaguchi Prefecture-based Asahi Shuzo Co., which is known for its famous Dassai brand of sake, introduced an AI system into the brewing process of Dassai on a trial basis in April.

Using an AI system developed by major information technology firm Fujitsu Ltd. and others, the company to aims to optimize brewing conditions.

To produce sake, rice is washed, steamed and then mixed with koji mold. After these processes, the rice turns into a kind of mash called moromi.

The moromi mash is then fermented for about 35 days, after which it is pressed to produce liquid sake.

It is during the fermentation stage that the company utilizes AI. The fermentation process requires extremely careful temperature control and for adjustments to be made by adding water.

The company had formerly made precise adjustments by relying on huge volumes of control records as well as the sense of veteran employees.

The AI system initially learned the brewing conditions of about 300 barrels (about 600,000 liters) of Dassai-brand sake produced in the past.

Inputting such factors as temperature, alcohol percentage and the level of glucose in the moromi being fermented, the AI system forecasts how active koji mold will be and how the temperature will fluctuate, among other factors.

In addition, the AI system compares the data with that of past fermentation processes, and gives workers advice on controlling the temperature, how much water will need to be added, and the timing of various actions.

Asahi Shuzo conducted a feasibility test twice using a total of four barrels. In the first test, the AI system and veteran workers often made different judgments. But in the second test, the company said that the AI system gave appropriate instructions in many instances.

However, on a day when the company was scheduled to press the moromi to extract sake, its facilities were damaged by the torrential rain that hit western Japan. As a result, it became impossible to evaluate the taste of the sake being produced with the help of the AI system.

But Hidetaka Nishida, chief of the company's production department, took a positive view of the experiment. "If we use the AI system also in the processes of washing and steaming rice, it's likely that we can utilize the system to brew sake products with more stable levels of quality."

Also for new types of beer

In summer last year, Kirin Co., a major beverage maker based in Tokyo, began developing AI systems to shorten the length of time necessary for developing new types of beer products.

In the development of new products, workers in the sales sections put forward various ideas. For example, some workers proposed a type of beer for women in their 30s who hold women-only parties. Others proposed a type of high density beer that men in their 40s can enjoy while relaxing.

Workers in charge of brewing receive the ideas and decide on conditions such as aroma and taste. They consider various recipes and how to process the ingredients.

Then, for about a month, they repeatedly conduct brewing tests to create products that can meet the requests of their colleagues in sales.

The company also has its AI system learn the conditions and outcomes of brewing tests conducted by the company in the past. If workers in charge of brewing input their planned recipes before starting a brewing test, the AI system can forecast what kinds of tastes and aromas the test products will have.

As consumer preferences about beer have diversified, the number of brewing tests has been on the rise. But the number of brewing plants is limited.

According to the company, it is increasingly necessary even for employees with less experience to be able to produce new types of beer in line with expectations.

One of the employees in charge said: "It's humans who consider recipes and produce beer. With the help of AI, we want to meet diversified needs."

Read more from The Japan News at https://japannews.yomiuri.co.jp/