"Cyber Wagashi [traditional Japanese sweets]," "Singularity sushi," and other outlandish names can possibly be listed on the menus of restaurants in the near future. You may wonder whether these are names of imaginary cuisine. But seeing is believing.

Cyber Wagashi has been developed by Open Meals, a team of companies and engineers seeking to create food of the future.

The Yomiuri Shimbun visited their factory in Tokyo in February, where we found a 3-D printer that is used to make Cyber Wagashi.

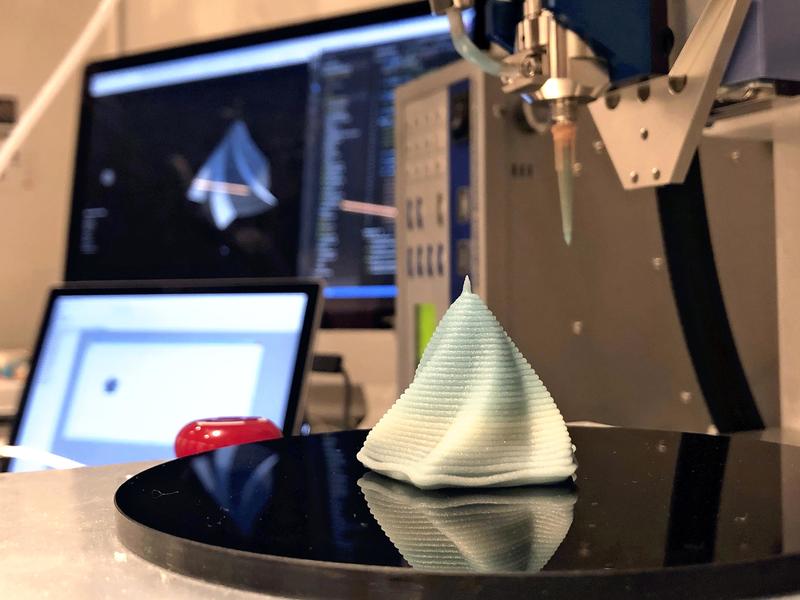

The printer contains nerikiri, a common material used in moist wagashi. The machine started with a buzz as it printed nerikiri in the shape of a 1-millimeter diameter thread, making it swirl and pile up precisely.

The design of the wagashi varies according to Tokyo weather data. That is, the colors, height, and swirls of each sweet respectively represent the air temperature, atmospheric pressure and wind velocity recorded on a specific day. The day chosen at this time was Jan. 13, 1876, the coldest day on record in Tokyo with a temperature as low as minus 9.2 C. In about 10 minutes, the 3-D printer had finished a sweet for me, which was obviously in cold colors. I later enjoyed the refined flavor.

"Its design is so detailed that a human couldn't make it by hand," said Shiho Sakamoto, 38, a wagashi artist and member of the team. "It'll encourage wagashi confectioners to make better designs."

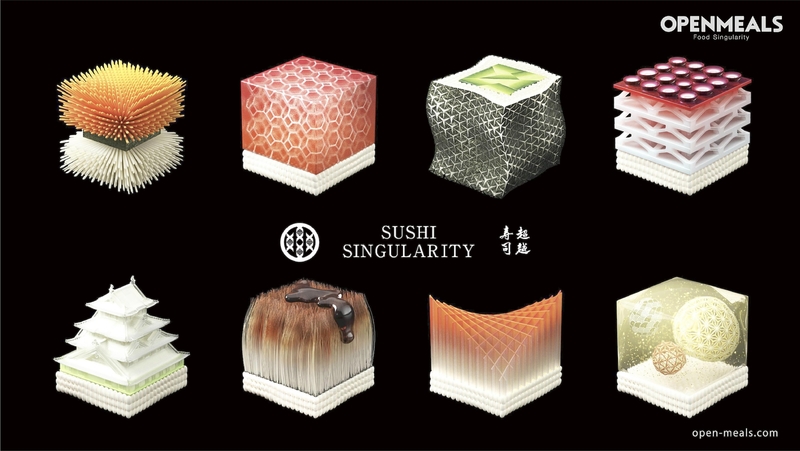

The team is currently developing a lineup of singularity sushi in its Food Singularity project, which looks more outlandish. For example, rice flour and powdered sea urchin are solidified by heat with a laser to make "Powdered Sintered Uni [sea urchin]," while "Micro Pillar Saltwater Eel" is made with ultra-fine filament-like saltwater eel gel, which extrudes from a 3-D printer.

The team not only focuses on fine, precise appearances. It is expected that foods in the future will be tailor-made to suit the health condition and taste buds of each consumer, so the team is pursuing the goal of creating perfectly tasty, healthy food by including nutrients needed by the individual.

Ryosuke Sakaki, 39, an art director at Dentsu Inc. and the team's representative, gave a bold prediction, saying, "I think 3-D printers will eventually become home cooking appliances to personalize foods."

The use of 3-D printers is rapidly spreading among food manufacturers.

In February, Swiss chocolate maker Barry Callebaut opened a large-scale 3-D printer workshop, which the company said is the first of its kind in the world. The workshop creates novel and delicate custom-made chocolates at the requests of European hotels and other clients.

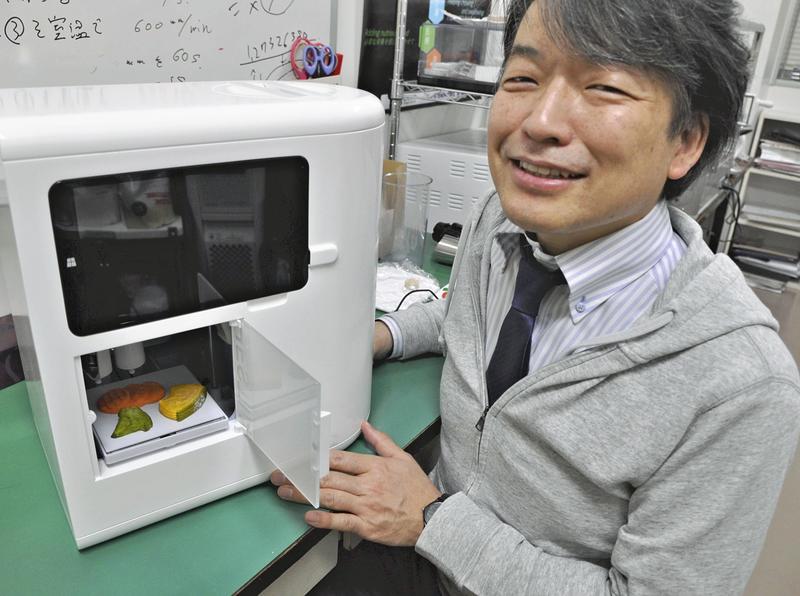

A team led by Hidemitsu Furukawa, 51, a professor at Yamagata University and materials science specialist, has been researching the making and improvement of nursing care food. A liquid diet for someone who needs nursing care does not look appetizing or very enjoyable to eat. To address this problem, the team, in collaboration with a food manufacturing company, developed a method to obtain the desired firmness and shape by adding agar and other substances to rice flour or commercially available nursing care foods. The team also designed a dedicated printer for this project.

The system can make foods that are visually appealing and "individually suited if it is possible to incorporate data of their chewing ability into the food designing process," Furukawa said. Automating cooking steps could reduce caregivers' workload, too.

Japan Aerospace Exploration Agency (JAXA) with private businesses has set up Space Food X, a project team aiming to develop technologies to make space food using 3-D printers.

If these systems become widespread, consumers may be able to easily buy hamburgers or sushi from 3-D printers as they currently buy foods from vending machines.

People from a century ago would be surprised to see today's cups of instant noodles and snacks, recognizing what foods of the future are like. Similarly, we may be living in a time when foods are changed by the power of technology.

An automatic cooking pot, named Hot Cook, developed by the major home electrical appliances manufacturer Sharp Corp., in Osaka Prefecture, can cook curry, stew, and many other dishes simply by adding ingredients and seasonings, according to more than 300 preset recipes.

The product uses sensor technologies to, for example, estimate the required heating time, before starting to cook, based on the amount of ingredients and determines whether the ingredients have been cooked through based on pressure sensed by a pair of stirring rods attached to the inside of the lid.

Automatic cooking pots like this product will soon be a daily necessity, the employee in charge said confidently.

The British company Moley Robotics is this year planning to launch a "robotic kitchen," which has two mechanical arms that dangle from the ceiling to cook. This unit stores digitized versions of a human chef's movements in its memory to cook foods and arrange them on plates automatically. If such robots could prepare foods on par with human chefs, work for chefs may possibly be no longer necessary.

In fact, more and more cooking robots have been introduced at restaurants facing serious manpower shortages. A soba noodle shop in JR Higashi Koganei Station in Koganei, Tokyo, used a robot chef in a demonstration test for a short period from mid-March to April 7.

The single-arm robot, installed in the shop's kitchen, did a series of cooking steps just as a human would, such as putting soba in boiling water, then removing it after being boiled, and washing it in cold water. Although the cooked soba is arranged on a plate by human, the robot is said to do almost the same amount of work as one human worker.

"Robots will be more widely used in the future," said Tetsuya Sawanobori, 38, chief executive officer of Connected Robotics Inc., which developed the machine.

Read more from The Japan News at https://japannews.yomiuri.co.jp/