If you ask most cyclists about high-technology products on their bikes, it's unlikely that the saddle will make the list. If you look at our list of the best road bike saddles, you'll find that idea reinforced again. We have options for short or long and different weights but most of what is there is relatively traditional. Despite that, there's a bit of a revolution happening in saddles.

Price: £490 / $490

Length: 262 mm

Width: 136-162 mm depending on the buyer

Weight: 180g as measured

Rail: 7x9 carbon

More info: posedla.com

The revolution that is pushing bike saddle technology is 3D printing and it started with Specialized. In 2020 Specialized was the first to use 3D printing technology from a California company named Carbon to create a saddle unlike anything else on the market. Since then, Specialized has moved on to a second generation, Fizik has put out two generations of saddles using the same technology, and both Sella San Marco and Selle Italia now have options as well. What all of those options share is that the technology underpinning them is the same.

Depending on your choice of available brands, the approach is still relatively old school. There are advantages to the products those brands are offering but they are far from the truly custom future of manufacturing that 3D printing promises. Posedla is a small Czech brand that aims to change that. The Joyseat isn't just 3D printed, it's handmade and custom 3D printed to your body.

Promises don't mean much though so I proposed an idea to put the saddle to the test. I flew across the world and spent 20 hours riding from Prague to Vienna on a Joyseat to see how it performed. Keep reading to see my thoughts on one of the most unique saddles available on the market.

Design and aesthetics

To understand the design of the Posedla Joyseat you have to start with an understanding of the man behind the company, Jiří Dužár. If you dig a bit you can get him to talk about the technology behind his saddle company but that's not where the passion seems to flow. Instead, almost every conversation seems to start and end with a discussion of the land that Posedla Manufacturing calls home.

While the bulk of the, very small, company calls Prague home. The manufacturing is set in a small area of Czech called North Bohemia. Specifically, a brown, nondescript building that sits inside a small town called Varnsdorf. It's an area that was once home to lots of manufacturing but as border closures took their toll, people and the manufacturing disappeared. Jiří wants to change that one saddle at a time but the goal isn't to go back to the old way of doing things.

Instead of the manufacturing of old, and the environmental devastation it brought with it, Jiří is bringing high-tech and sustainable manufacturing. In truth though, it's a mix of high-tech and low-tech. The low-tech side is where the manufacturing of the carbon fibre base and rails falls.

Actually, manufacturing is only a loose description. As you walk into the facility. Everything is newly unpacked and there is lots of empty space. The production floor consists of a table where two women, who someone surely calls babička (grandma), sit with a mould each in front of them. The production supervisor helps get carbon prepreg out of freezers not much bigger than what you'd find in a house and these women lay it into the mould in front of them.

Each woman is working on a single side of the rail. When they've finished it goes into a vacuum bag at room temperature. When that process finishes, it comes out and a small tube of unidirectional carbon gets placed into one side before the second side of the mould gets placed on top and the two sides are bolted together. From there, the whole thing gets vacuum sealed again before finally going through a baking process. At the end, the finished rails come out of the moulds and go through a sanding and finishing step.

Although the material is carbon fibre, the whole process is as low-tech as you could possibly imagine. This process is also the current opportunity for optimization and it's the reason for the long lead times. The three people working together can only manage 6 sets of carbon rails in an 8-hour shift and timing is always critical. Nothing can get started that isn't able to finish the same day so even a small disruption will adjust the whole schedule. It's possible to stockpile these parts but speeding up the process will be capital-intensive so there's an open question of when to make the jump.

At the same time the low-tech side of the manufacturing is happening in Jiří's hometown, a very different process is taking place not far away. The 3D-printed upper half of the saddle is almost the complete opposite of the carbon fibre base and rails. While one is low-tech and handmade, the other is high-tech and hands-off.

To complete the upper, Posedla gathers data and it's transmitted electronically to 3D printing partner BASF. BASF uses the data to create the upper part of the saddle without the need for virtually any human touch and the finished pieces head from Germany back to Posedla in the Czech Republic. It's fast, efficient, and hands-off.

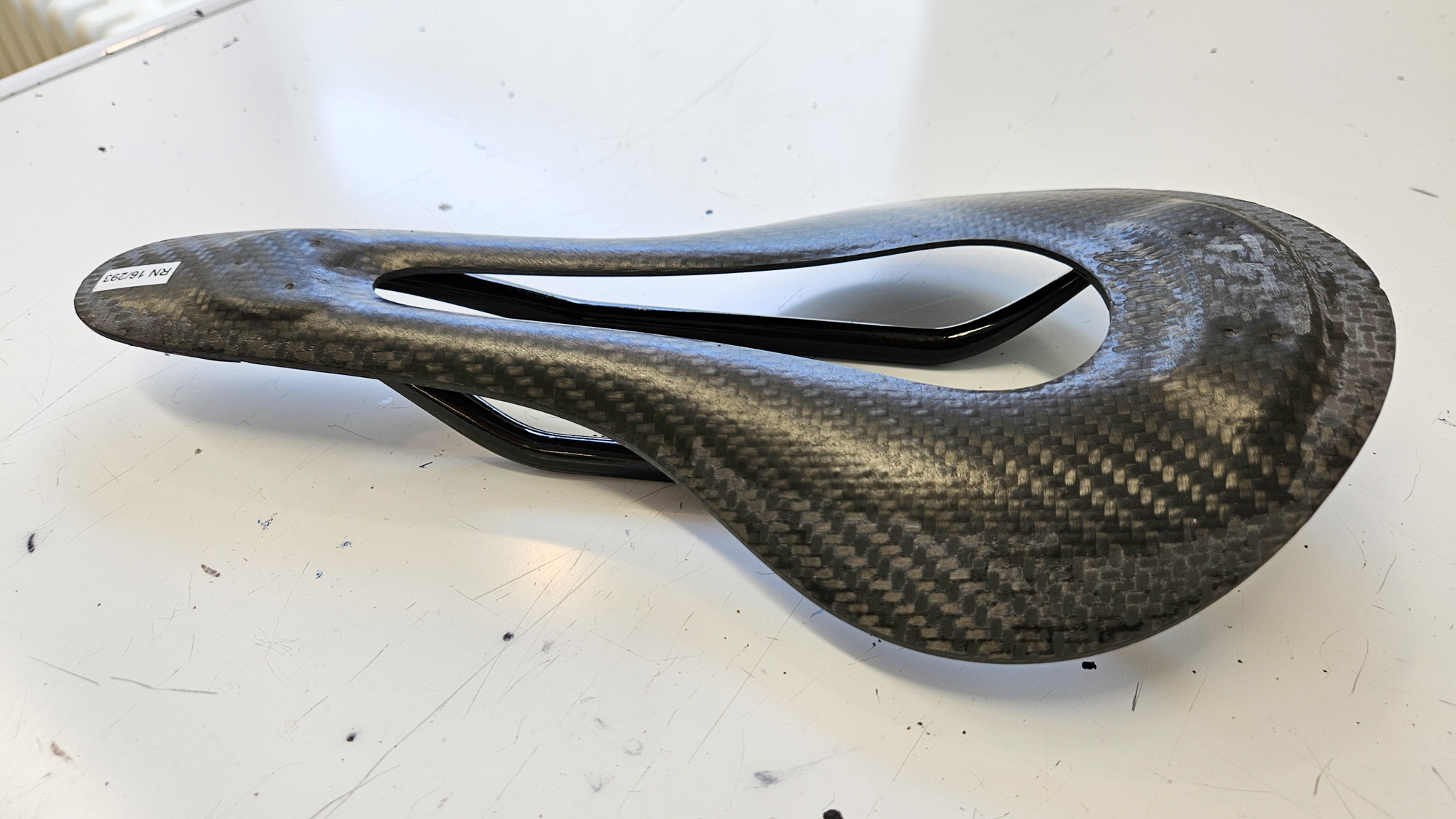

It's also different from other saddles on the market. Every other 3D printed saddle currently on the market is being manufactured using a Carbon technologies liquid polymer 3D printer. Posedla is instead using a powder-based 3D printing technology from HP. HP is a leader in digital press technology and this is an adaptation of that same tech.

Despite that difference though, it's not drastically different to the consumer. Both systems end up with a lattice structure that allows for precise tuning of the feel. Visually it's more rounded. While Carbon saddles use nodes and lines that look like triangles when finished, the Posedla saddle is a collection of rounded holes. The edges of the saddle mirror that look with a very rounded aesthetic to both the centre cutout and to the nose as well as the rear. There's maybe a little throwback to 90's design energy here but it doesn't impact the performance one way or the other. When everything is combined you end up with a 180-gram carbon saddle with a carbon base and 3D-printed upper. It’s on the shorter side, similar to Fizik and Sella San Marco, at 262mm and the final width will be between 136 and 162mm depending on your needs.

The advantage of using BASF is more about the goals close to Jiří's heart. Instead of incurring the carbon footprint of extensive shipping, BASF is a local company. Also falling in line with company goals is the fact that it's possible to return the finished piece to powder form for reuse. Remember, sustainability and locality are both goals for Jiří.

The custom moulding process

As with the discussion of the design, it's necessary to take a step back when starting the discussion of the performance. This isn't a saddle you'll simply pick out from a web page then attach to your bike and go. What makes the Posedla Joyseat unique, and special, is that it's made for you. There will be others in the world like it but none of them will be exactly the same.

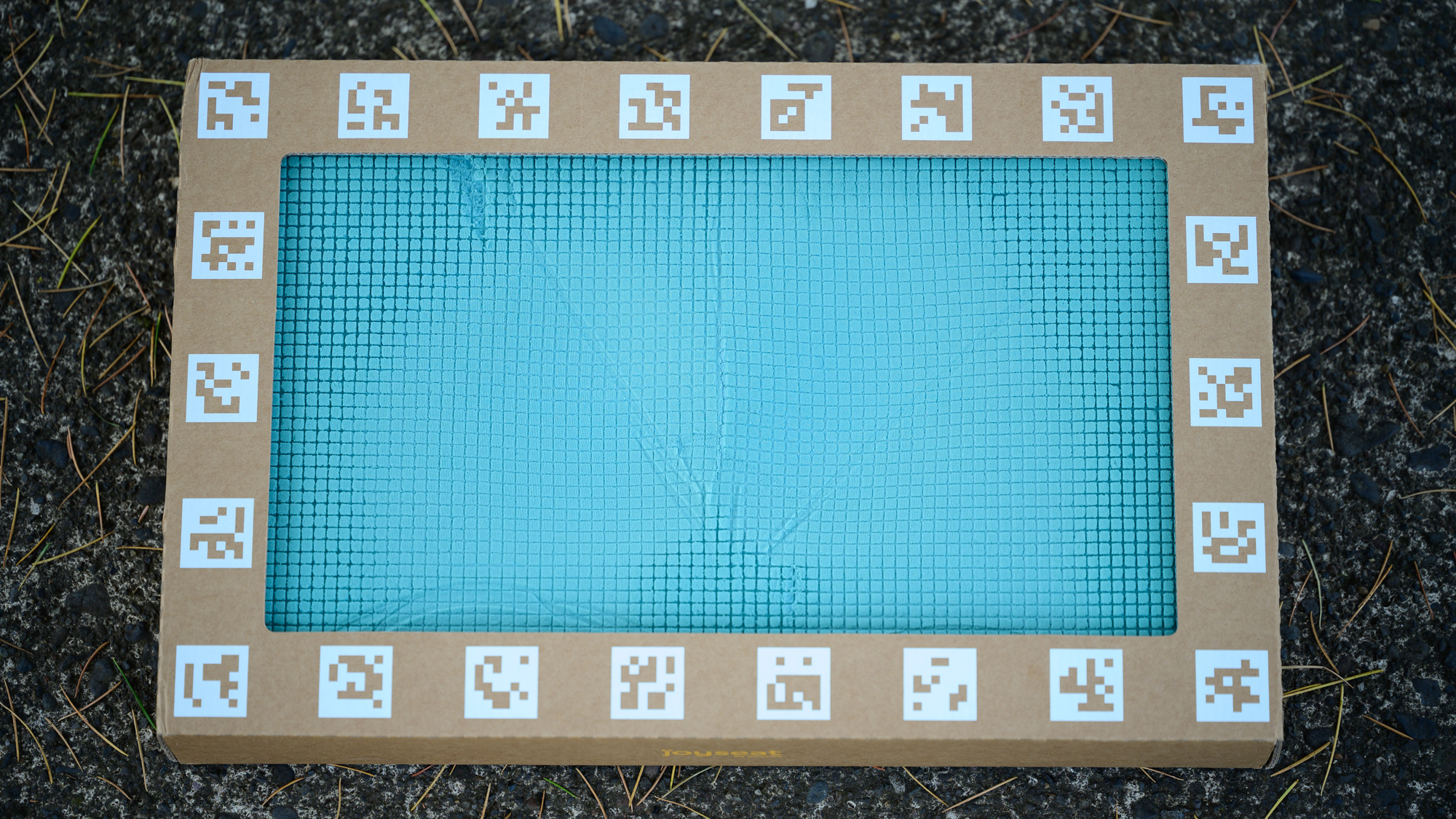

My journey with the Joyseat started, like everyone, with a simple question on the Posedla website. Was I choosing a road gravel, or mountain bike saddle? With that answered, the add to cart button added not just a saddle but also the Smiling Butt Kit. Then, with payment provided, it isn't a saddle that gets added to the shipping queue but rather the Smiling Butt Kit.

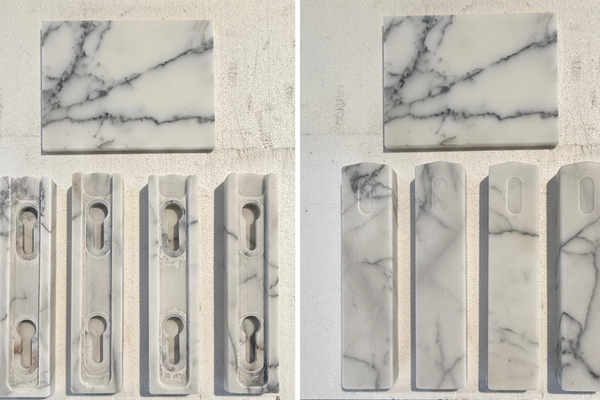

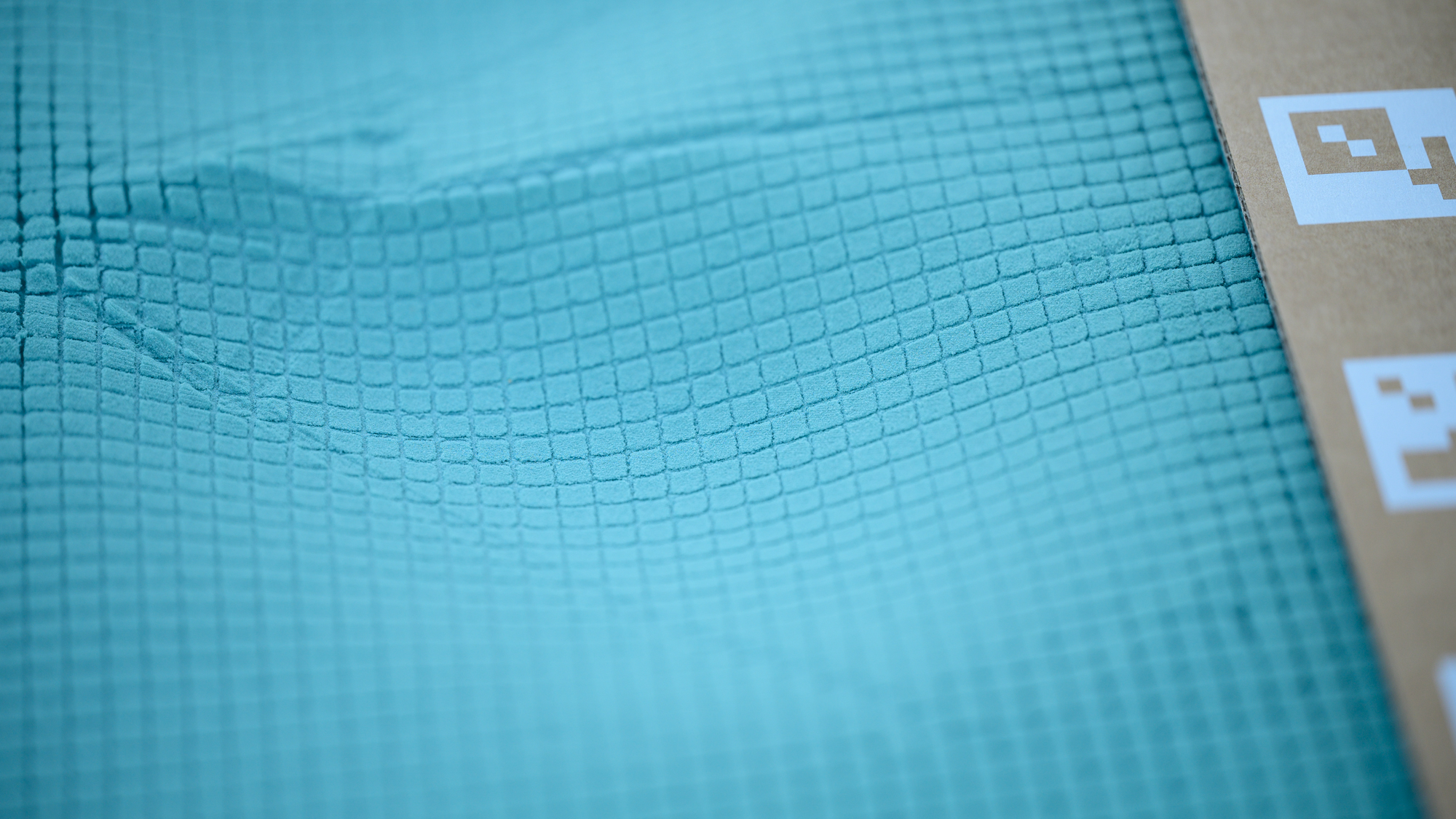

The Smiling Butt Kit is as much the magic of the Joyseat as any other part of the system. The heart of it is a foam that you sit on to create an impression. You don't send the foam back to Posedla though, instead, there's a series of QR codes around the edges of the box that holds the foam. Once you've made an impression you just take a series of images, covering all angles and the QR codes, and the Posedla software depth maps the impression. The fidelity is 5mm and the process is similar in principle to landscape mapping.

The pictures aren't the only part of the custom process though. The next step is a series of questions about your riding. Things like age and gender, there's a different profile for women, and things like flexibility and typical ride distances all play into the final design of your saddle. There are also purely cosmetic custom options such as a colour detail and engraving. When you've answered everything, the images will go through a check and when that's done, the foam isn't needed anymore. The process is complete and it's just a matter of waiting. If there was ever an issue, the two parts of the saddle are mechanically joined so it's possible to separate them and replace the upper.

Performance

My own experience with the Posedla Joyseat was a little different from the norm. Although I went through the same at-home moulding process, I didn't get the saddle shipped to my house. Instead, I got on a plane and headed for Prague to test the saddle the way I like to test things, with a stupid long ride. In this case, the ride was 370 km / 230 miles with 4267 metres / 14,000 ft from Prague to Vienna.

I didn't immediately set out on that ride though. Instead, my first opportunity to take a look at the Joyseat was at a world-class bike shop just outside of Prague called SBCR. It's an excellent place to launch a big ride in Czech and for me, it was an opportunity to start things on a new bike, and a new saddle, with a bike fit. It also meant that I got to see not only my specific saddle but also a collection of other Joyseats. Right away, I regretted not adding colour to my saddle.

It's a small thing that's not specifically related to the performance of this saddle but I have to mention it. The padding of the Joyseat is essentially a "U" shape. Starting at each rear corner, it comes to the front and follows the shape of the centre cutout before ending at the opposite rear corner. In the rear behind the cutout is a depression with a bit of plastic replacing the padding. That bit of plastic has a Posedla logo and during the order process, there's an option to pick a colour. As I said, it's a small thing but the colours are rich and really quite beautiful. The nature of my job is that I am constantly changing bikes and kit so I went with black for purposes of matching but when you order, pick a colour.

The other thing I did when the saddle first got mounted to the Festka I was riding was push on it. I think everyone naturally does this with saddles but 3D-printed saddles are inherently different from traditional saddles. The reason saddle companies turn to 3D printing is that the technology allows for infinite variability, and pinpoint accuracy, in how the padding responds. Instead of general areas where the padding is stiffer, 3D printing allows for a huge range. The best 3D printed saddles make use of this by being softer in most places but still having the density you need under your sit bones.

Posedla and the Joyseat exhibit the best of what you can expect in a 3D saddle. The nose is easily compressed under your thumb while the area under the sit bones is almost completely unyielding with a thumb press. The outer edges of the wings of the saddle are somewhere in between.

Of course, all of this is unique to my Joyseat saddle. I ride around 16,000 km / 10,000 miles a year in an aggressive road bike position. I also don't rotate my hips forward all that much and though I'm flexible, I tend to do the bending higher up my back. That detail about my flexibility means my saddle has a slight wave to it.

When I actually rode the Joyseat, it felt like an old friend. You know that saddle you've used forever and know you can depend on? That's what you get right from the first ride with the Joyseat. I found it easy to transition between standing and sitting and on shorter rides, where I move around a lot, I always seemed to be in the right spot.

After 16 hours of pedalling, and 20 hours elapsed time, with the Joyseat those initial impressions didn't change much. On long rides, I spend more time locked in something approaching my TT position and this time, I never experienced any numbness. I loved how the slight wave allowed me to stay stable in my position even as the hours dragged on. I did notice though, as I was on a bike that was slightly too big, that the padding was so exact that I sometimes moved off the ideal spot for my sit bones as I subtly tried to correct the oversized bike. I wouldn't consider that a mark against the saddle but you'll want to make sure your bike is right for you. Given most people won't be on a borrowed bike a world away from home, I suspect you won't have an issue but it's worth consideration.

Verdict

What sums up my experience with the Posedla Joyseat is that I spent 20 hours sitting on it and at the end, I still liked it. Yes, I was on a great bike with a great pair of bib shorts but those kinds of hours exaggerate any issues you might have. I didn't give myself an opportunity to back out of using this saddle, I just jumped in and put it to the test. Now that I'm back home, I'll be picking a different bike to put it on. That is high praise in terms of the actual performance.

If we stick to a purely product-focused discussion about the Joyseat, my only real question is how necessary it is. It's an expensive saddle and, at least right now, it takes a long time to get it in your hands. I happen to find myself right at the top of the bell curve for most cycling products. That means if a company, like Fizik, is averaging the data collected from a range of customers, it's probably perfect for me. If that's you, it might not be necessary to go for a custom saddle. If you fall outside of that perfect placement, the Joyseat makes a lot of sense.

The Joyseat also makes a lot of sense if you just aren't sure. If you've struggled to find what works and you've got a growing collection of saddles, maybe it's time to try something different. The Posedla system automates the whole process of finding the perfect saddle for you.

There's another layer to the discussion though. The Joyseat is a great saddle but Posedla has an incredibly compelling backstory. It's a group of cyclists who started a company to bring sustainable manufacturing back to a region of the world that could use it. It's not just top-down either. When I spoke to a young road racer/customer service agent for Posedla, she told me she was also from the same area in Northern Czech. She also told me that the goal of sustainable revitalization mattered to her as much as it did to Jiří. If you like putting your money behind a great story, Posedla has a great story. I'd bet you could even follow in my footsteps and pick up your saddle in person, the area is worth a visit.